Expanded polytetrafluoroethylene artificial dura mater and preparation technique thereof

A technology of polytetrafluoroethylene and artificial dura mater, which is applied in prosthesis, medical science, etc., can solve the problems of thin thickness and poor anti-sticking performance, and achieve the effects of simple process, convenient operation, reduced volume and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

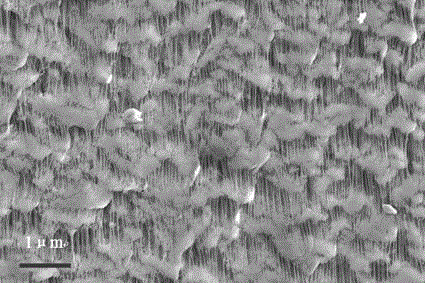

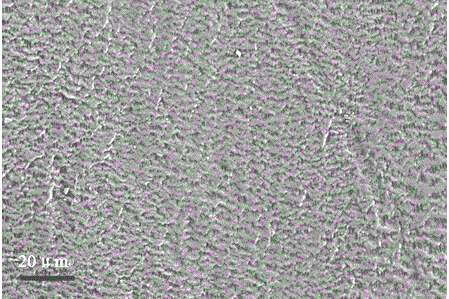

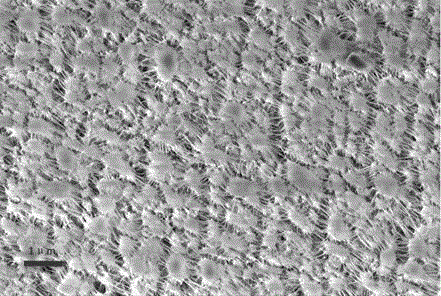

Image

Examples

Embodiment 1

[0048] S1, mixing materials: the polytetrafluoroethylene of 70% Teflon 601A brand and the isoparaffin solvent oil Isopar-L of 30% mass fraction are mixed uniformly by mass fraction;

[0049] S2, aging: aging the mixture obtained in step S1 at 50°C for 12h;

[0050] S3. Paste extrusion: send the product in the step S2 to an extruder for extrusion, the compression ratio during extrusion is 30, the extrusion temperature is 50°C, and the extrusion pressure is 3Mpa;

[0051] S4. Calendering: send the product in the step S3 to a calender for calendering to obtain a polytetrafluoroethylene base tape. The thickness of the polytetrafluoroethylene base tape is 1.2 mm and the width is 12 cm. During the calendering process, the calendering The speed of the two rollers of the machine is 3m / min;

[0052] S5. Degreasing: degreasing the polytetrafluoroethylene tape obtained in step S4 at 220° C.;

[0053] S6, longitudinal stretching: the product of the step S5 is subjected to longitudinal s...

Embodiment 2

[0057] The invention provides an expanded polytetrafluoroethylene artificial dura mater. The dura mater is prepared by mixing polytetrafluoroethylene whose raw material brand is Daikin F106 and isoparaffin solvent oil Isopar-C.

[0058] The present invention also provides a preparation process of expanded polytetrafluoroethylene artificial dura mater, comprising the following steps,

[0059] S1, mixing materials: the Daikin F106 brand polytetrafluoroethylene with a mass fraction of 75% and the Isopar-C with a mass fraction of 25% are mixed evenly;

[0060] S2, aging: aging the mixture obtained in step S1 at 35°C for 12h;

[0061] S3. Paste extrusion: send the product in step S2 to an extruder for extrusion, the compression ratio during extrusion is 50, the extrusion temperature is 50°C, and the extrusion pressure is 4 Mpa;

[0062] S4, calendering: Send the product in the step S3 to a calender for calendering to obtain a polytetrafluoroethylene base tape, the thickness of the...

Embodiment 3

[0068] The invention provides an expanded polytetrafluoroethylene artificial dura mater. The dura mater is prepared by mixing polytetrafluoroethylene whose raw material brand is Daikin F106 and isoparaffin solvent oil Isopar-C.

[0069] The present invention also provides a preparation process of expanded polytetrafluoroethylene artificial dura mater, comprising the following steps,

[0070] S1, mixing materials: the Daikin F104 brand polytetrafluoroethylene with a mass fraction of 74% and the Isopar-L with a mass fraction of 26% are mixed evenly;

[0071] S2. Aging: aging the mixture obtained in step S1 at 30° C. for 24 hours;

[0072] S3, Paste extrusion: Send the product in the step S2 to an extruder for extrusion, the compression ratio during extrusion is 40, the extrusion temperature is 40°C, and the extrusion pressure is 1 Mpa;

[0073] S4, calendering: Send the product in the step S3 to a calender for calendering to obtain a polytetrafluoroethylene base tape, the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com