A kind of polyaniline modified bentonite nano microsphere adsorption material and preparation method thereof

A technology of adsorption materials and nano-microspheres, applied in chemical instruments and methods, and other chemical processes, can solve problems such as increased investment costs, secondary pollution, and poor adsorption compatibility, and achieve the effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

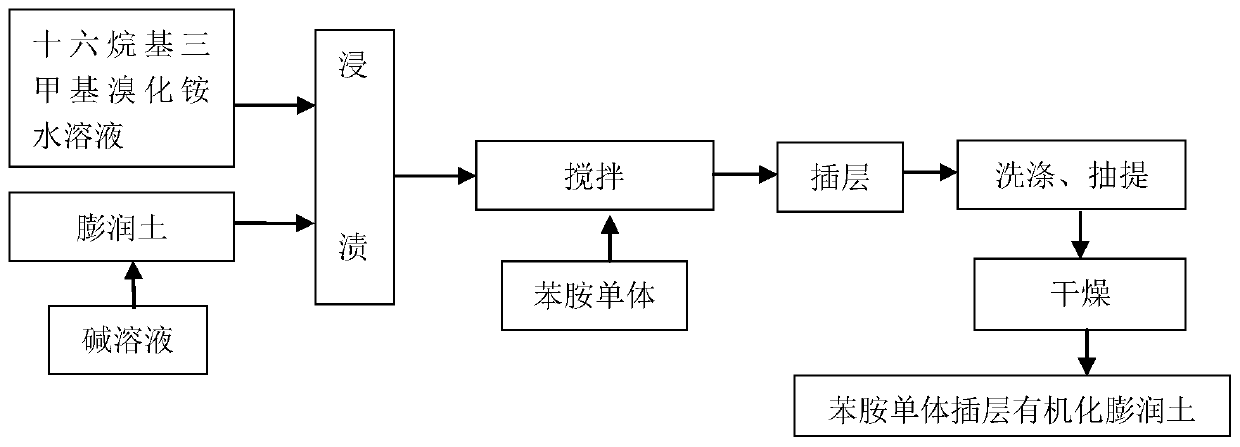

[0062] The first step, organicization of bentonite and preparation of aniline monomer intercalation:

[0063] Select 10% bentonite, add 75% distilled water, 0.02% surfactant cetyltrimethylammonium bromide, 11.7% sodium hydroxide, and mix in a container; heat in a water bath at 40°C for 2 hours for impregnation; then add 3. 28% aniline, continue heating in a water bath to 60°C, and stir for 4 hours to intercalate aniline into the interlayer of bentonite; obtain organic bentonite intercalated with aniline monomer.

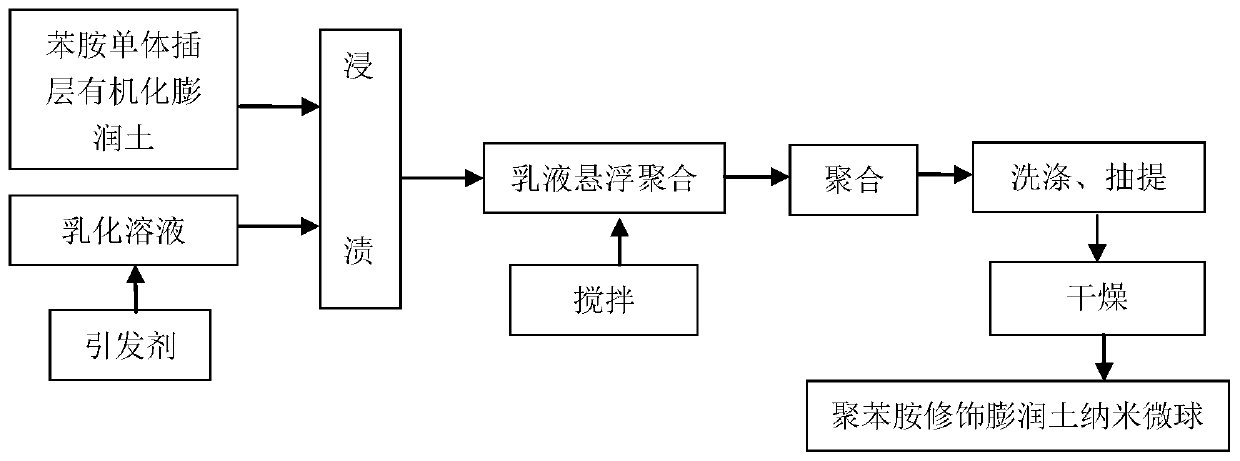

[0064] The second step, the preparation of polyaniline-modified bentonite nano-microsphere adsorption material:

[0065] Select 10% of the aniline monomer intercalated organic bentonite prepared in the first step of the present invention, add 80% distilled water, 0.3% emulsifier Span60, and 9.68% sodium hydroxide, mix in a container to prepare a suspended aqueous solution, After stirring and heating for a period of time, add 0.02% of the initiator ferric chloride dr...

Embodiment 2

[0067] The first step, organicization of bentonite and preparation of aniline monomer intercalation:

[0068] Select 14.5% bentonite, add 65% distilled water, 0.04% surfactant cetyltrimethylammonium bromide, and 14.5% sodium hydroxide, mix in a container; heat in a water bath at 42°C for 1.5h, and impregnate; then Add 5.96% aniline, continue heating in a water bath to 62° C., and stir for 3.2 hours to intercalate aniline into the interlayer of bentonite; obtain organic bentonite intercalated with aniline monomer.

[0069] The second step, the preparation of polyaniline-modified bentonite nano-microsphere adsorption material:

[0070] Select 16% of aniline monomer intercalated organic bentonite prepared in the first step of the present invention, add 72% distilled water, 0.4% emulsifier Span60, and 11.56% sodium hydroxide, mix in a container to prepare a suspended aqueous solution, After stirring and heating for a period of time, add 0.06% of the initiator ferric chloride drop...

Embodiment 3

[0072] The first step, organicization of bentonite and preparation of aniline monomer intercalation:

[0073] Select 20% bentonite, add 60% distilled water, 0.06% surfactant cetyltrimethylammonium bromide, 12.4% sodium hydroxide, and mix in a container; heat in a water bath at 50°C for 1 hour for impregnation; then add 7.54% aniline, continue to heat in a water bath to 70°C, and stir for 2 hours to intercalate aniline into the interlayer of bentonite; obtain organic bentonite intercalated with aniline monomer.

[0074] The second step, the preparation of polyaniline-modified bentonite nano-microsphere adsorption material:

[0075] Select 10% of the aniline monomer intercalated organic bentonite prepared in the first step of the present invention, add 80% distilled water, 0.3% emulsifier Span60, and 9.68% sodium hydroxide, mix in a container to prepare a suspended aqueous solution, After stirring and heating for a period of time, add 0.02% of the initiator ferric chloride drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com