Ag2Mo2O7@AgBr composite photocatalyst and preparation method thereof

A composite catalyst, ag2mo2o7 technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of quantum yield photogenerated electron-hole pair recombination rate defects, application obstacles, etc. Strong controllability, high degradation efficiency, simple and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

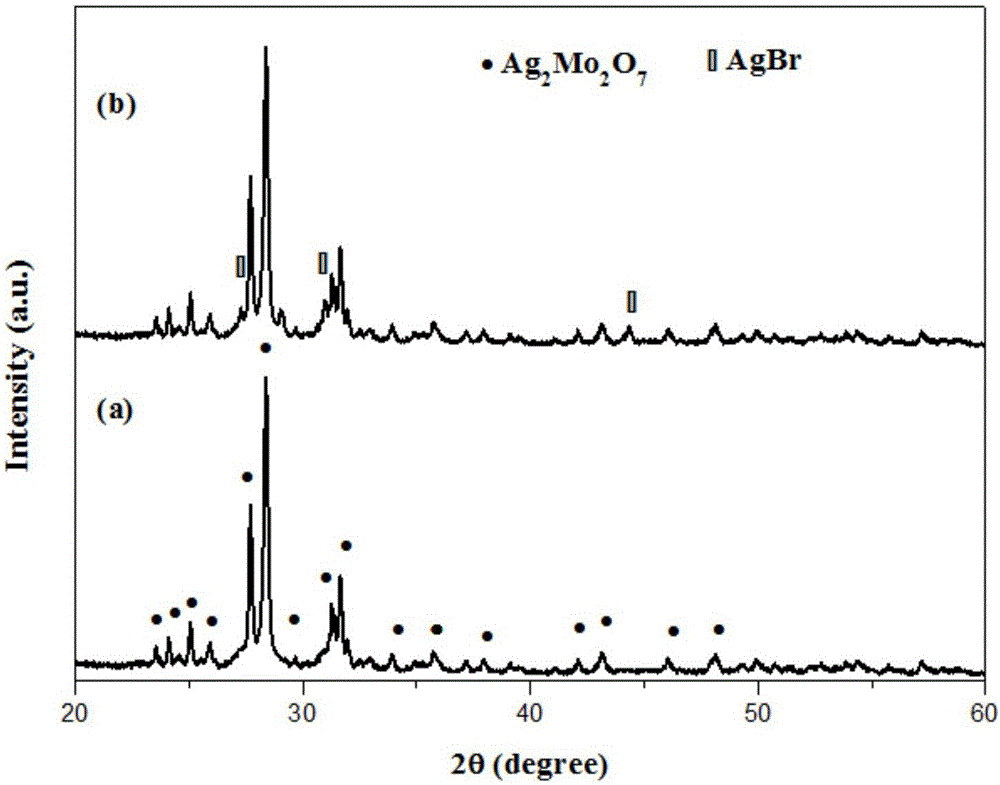

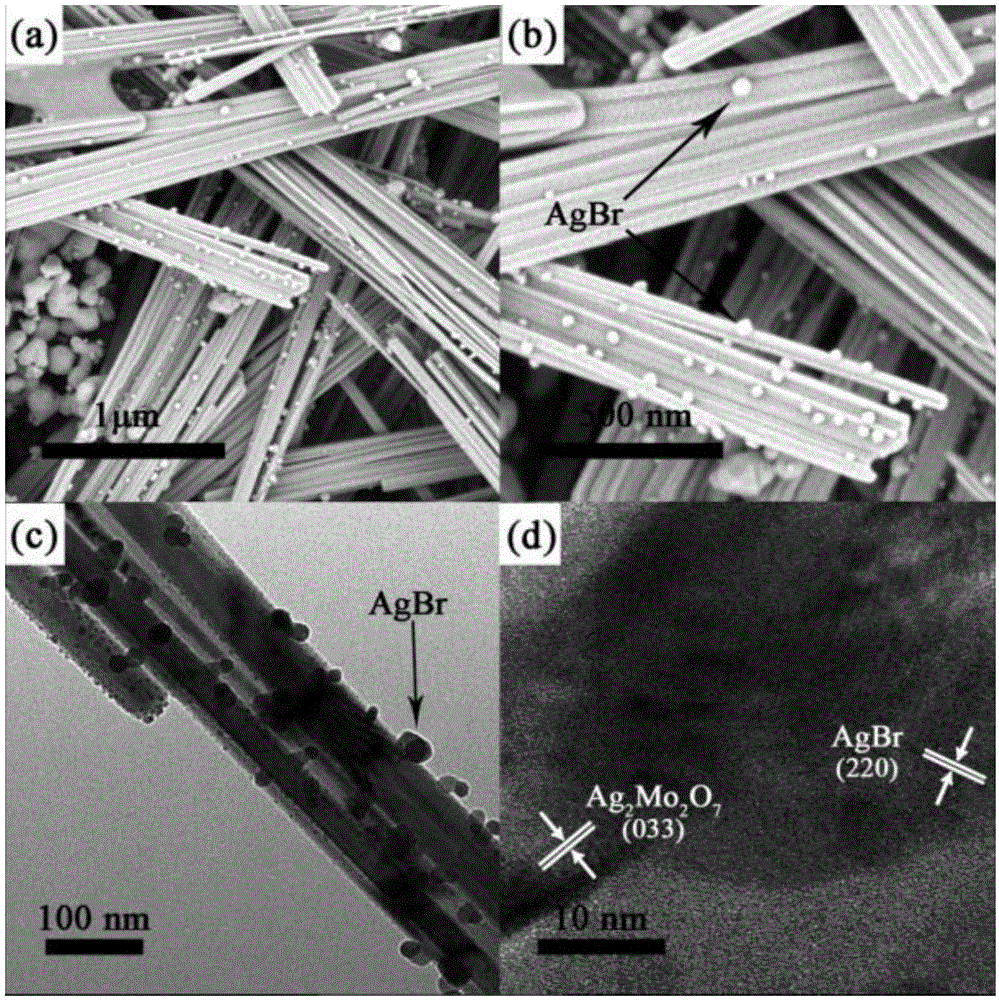

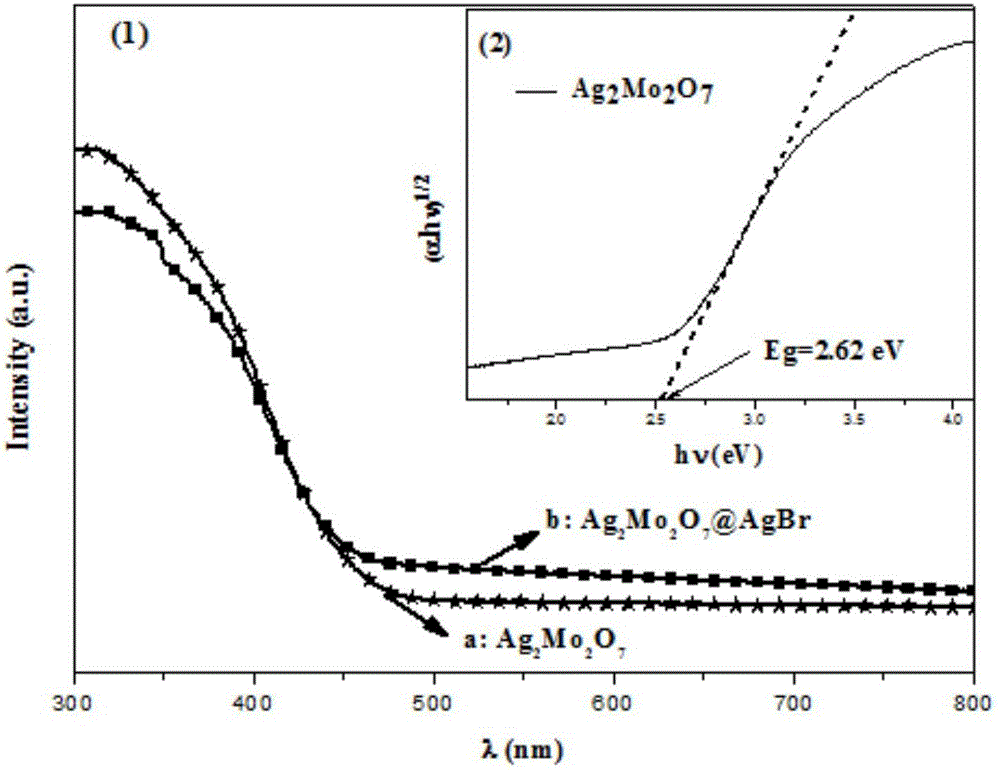

Image

Examples

Embodiment 1

[0035] Ag in this example 2 Mo 2 o 7 @AgBr composite photocatalyst, the specific preparation steps are as follows:

[0036] a) 2mmol AgNO 3 Dissolve in 50mL deionized water, add NH dropwise after complete dissolution 3 ·H 2 O, forming silver ammonium ion solution for subsequent use. At the same time 0.3mmol ammonium molybdate (NH 4 ) 6 Mo 7 o 24 Completely dissolve in 30mL deionized water, add the silver ammonia ion solution drop by drop under stirring condition, finish with HNO 3 Adjust the pH of the solution at 2. Transfer the above mixed solution to a 250mL round-bottomed flask, and react at a constant temperature of 60°C for 20h under stirring conditions. After the reaction, the product was washed with deionized water and absolute ethanol three times respectively, and the collected product was dried in an oven at 50°C for 12h. get Ag 2 Mo 2 o 7 powder.

[0037] b) Take 0.5196g Ag 2 Mo 2 o 7 The sample was ultrasonically dispersed in 30mL of deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com