Environment-friendly preparing method of nanometer copper with ascorbic acid and Arabic gum serving as reducing agent and protective agent

A technology of gum arabic and ascorbic acid, which is applied in the field of preparation of nano-copper particles, can solve problems such as inability to apply large-scale production well, waste of human and material resources, etc., and achieve the effects of reducing waste, low cost, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 0.3 g of gum arabic, add it to a 250 mL three-neck flask, add 15 mL of deionized water, dissolve it under magnetic stirring, and make a gum arabic solution;

[0028] Weigh 0.05 g of copper sulfate pentahydrate and add it to a 50 mL beaker, add 5 mL of deionized water, and dissolve it under magnetic stirring to form a copper sulfate solution;

[0029] Pour the prepared copper sulfate solution into a three-necked flask containing gum arabic solution, raise the temperature to 50°C, and stir magnetically for 10 minutes to mix the two evenly to obtain a gum arabic-copper sulfate mixed solution;

[0030] Weigh 0.3 g of ascorbic acid, add it to a 50 mL beaker, and add 10 mL of deionized water to make an ascorbic acid solution with a mass concentration of 0.15 g / mL;

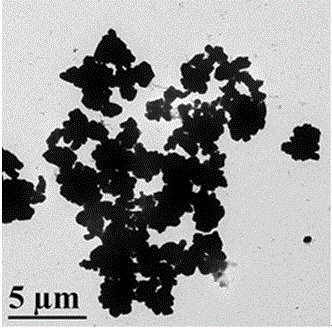

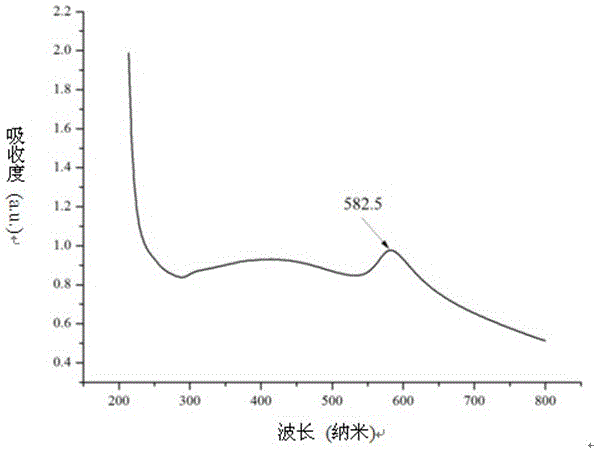

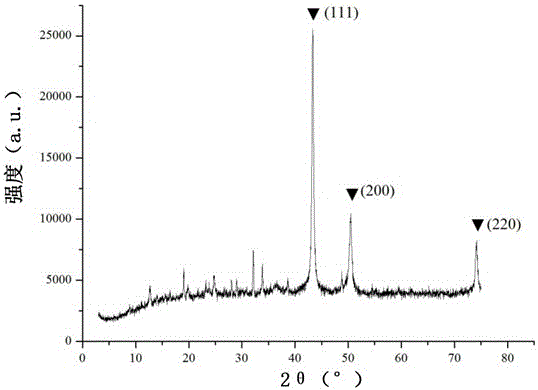

[0031] Under the action of magnetic stirring, the ascorbic acid solution was added dropwise to the mixed solution of gum arabic-copper sulfate, the temperature was raised to 50°C, and the magnetic stirring w...

Embodiment 2

[0034] Example 2: Same as Example 1, but the amount of gum arabic in step (1) is changed to 0.5 g, and the amount of deionized water is changed to 150 mL.

Embodiment 3

[0035] Example 3: Same as Example 1, but the amount of copper sulfate pentahydrate in step (2) is changed to 0.1 g, and the amount of deionized water is changed to 20 mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com