A method for preparing battery negative electrode active material calcium zincate by jet mill

A technology of battery negative electrode and active material, applied in battery electrodes, nickel storage batteries, alkaline storage batteries, etc., can solve the problems of low charge-discharge performance and cycle performance, long production time, low stability, etc., to avoid the phenomenon of flatulence , The effect of large production capacity and uniform fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The method for preparing the battery negative electrode active material calcium zincate by jet mill of the present embodiment comprises the following steps:

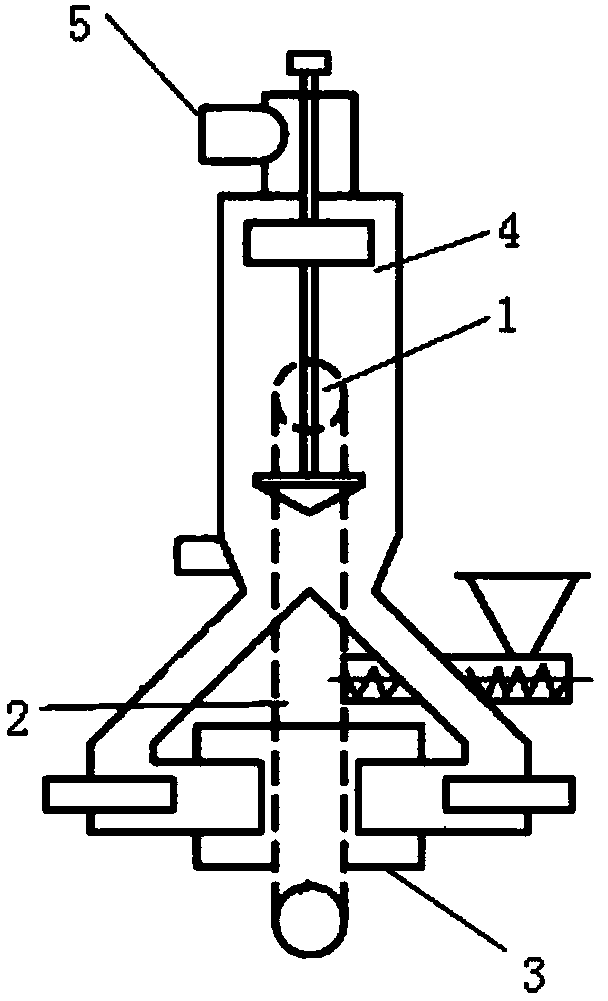

[0037] Step 1: After mixing and stirring zinc oxide, calcium hydroxide and deionized water in a weight ratio of 4:4:1, the particle diameters of the zinc oxide and calcium hydroxide are both 50-150 mesh, and put them into the jet mill Material inlet 1, the pressure of the material inlet 1 is 0.4-0.8MPa, and then enters the crushing chamber 3 through the riser 2, the pressure of the crushing chamber 3 is 0.002-0.01MPa, and the crushed material is obtained;

[0038] Step 2: Enter the pulverized material obtained in Step 1 into the classification chamber 4 for classification, and the speed of the classification is 3000-6000 rpm to obtain the classified particles;

[0039] Step 3: The classified particles obtained in step 2 are returned to the crushing chamber (3) with a particle size of ≤1000 mesh for re-grinding; th...

Embodiment 2

[0041] The method for preparing the battery negative electrode active material calcium zincate by jet mill of the present embodiment comprises the following steps:

[0042] Step 1: After mixing and stirring zinc oxide, calcium hydroxide and deionized water in a weight ratio of 6:6:1, the particle diameters of the zinc oxide and calcium hydroxide are both 50-150 mesh, and put them into the jet mill Material inlet 1, the pressure of the material inlet 1 is 0.4-0.8MPa, and then enters the crushing chamber 3 through the riser 2, the pressure of the crushing chamber 3 is 0.002-0.01MPa, and the crushed material is obtained;

[0043] Step 2: Enter the pulverized material obtained in Step 1 into the classification chamber 4 for classification, and the speed of the classification is 3000-6000 rpm to obtain the classified particles;

[0044] Step 3: The classified particles obtained in step 2 are returned to the crushing chamber (3) with a particle size of ≤1000 mesh for re-grinding; th...

Embodiment 3

[0046] The method for preparing the battery negative electrode active material calcium zincate by jet mill of the present embodiment comprises the following steps:

[0047] Step 1: After mixing and stirring zinc oxide, calcium hydroxide and deionized water in a weight ratio of 5:5:1, the particle diameters of the zinc oxide and calcium hydroxide are both 50-150 mesh, and put them into the jet mill Material inlet 1, the pressure of the material inlet 1 is 0.4-0.8MPa, and then enters the crushing chamber 3 through the riser 2, the pressure of the crushing chamber 3 is 0.002-0.01MPa, and the crushed material is obtained;

[0048] Step 2: Enter the pulverized material obtained in Step 1 into the classification chamber 4 for classification, and the speed of the classification is 3000-6000 rpm to obtain the classified particles;

[0049] Step 3: The classified particles obtained in step 2 are returned to the crushing chamber (3) with a particle size of ≤1000 mesh for re-grinding; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com