Heat-treatment recycling method for excrement

A technology of recycling and excrement, applied in pyrolysis treatment of sludge, chemical instruments and methods, sludge treatment, etc., to achieve the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

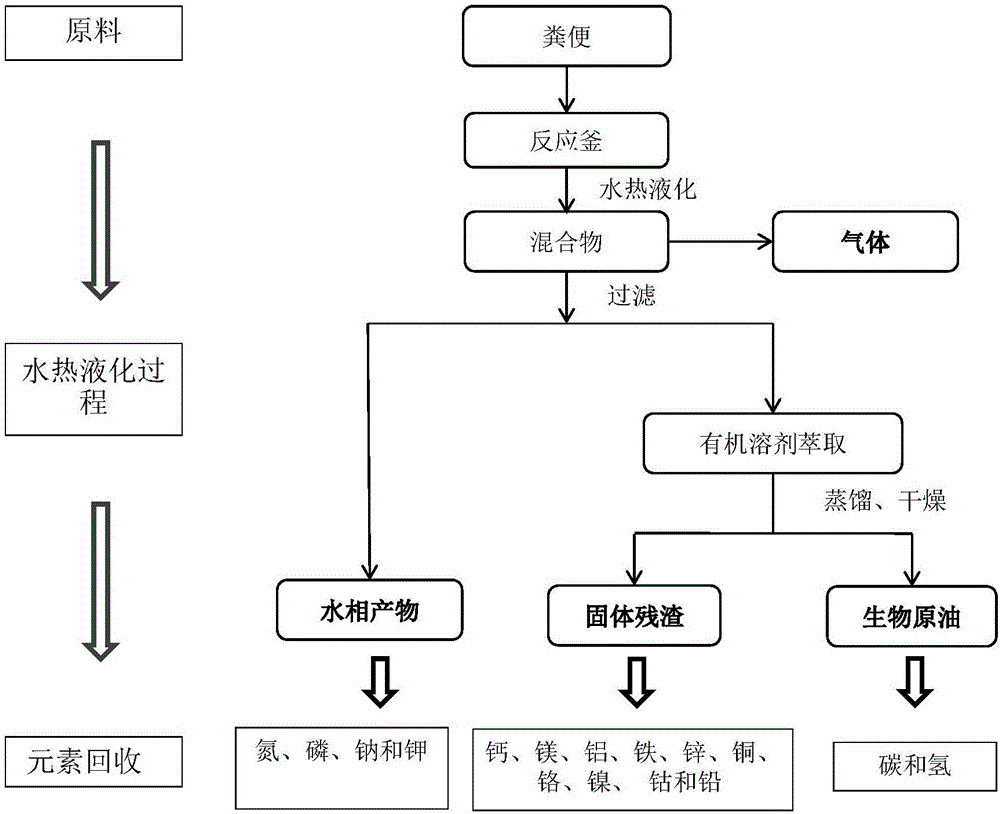

Method used

Image

Examples

Embodiment 1

[0044] A method for fecal heat treatment and recycling, including the following steps:

[0045] a) Add 50 g of pig manure with a water content of 80% into the reaction kettle, then seal the reaction kettle, and give an initial pressure of 4 MPa with gas.

[0046] b) Heat the reaction kettle to 320°C for 180 minutes, then stop heating.

[0047] c) Cool to room temperature, first connect a 2L gas bag to the gas outlet of the reactor for gas collection; then open the reactor to collect the remaining mixture; filter the remaining mixture to obtain an aqueous phase containing Na, K, and P elements and remaining substances .

[0048] The recovery rate of Na, K, N and P elements in the water phase was detected. Na and K elements were determined by inductively coupled plasma emission spectrometer; N and P elements were determined by potassium persulfate oxidation method and molybdenum antimony spectrophotometric method.

[0049] After testing, the recovery rate of Na, K, N and P elements in pi...

Embodiment 2

[0057] A method for fecal heat treatment and recycling, including the following steps:

[0058] a) Add 30 g of human feces with a water content of 75% into the reactor, then seal the reactor, and give an initial pressure of 2 MPa with gas.

[0059] b) Heat the reactor to 450°C for 0 min, then stop heating.

[0060] c) Cool to room temperature, first connect a 2L gas bag to the gas outlet of the reactor to collect gas; then open the reactor to collect the remaining mixture; filter the remaining mixture to obtain an aqueous phase containing Na, K, and P elements and remaining substances .

[0061] The recovery rate of Na, K, N and P elements in the water phase was detected. Na and K elements were determined by inductively coupled plasma emission spectrometer; N and P elements were determined by potassium persulfate oxidation method and molybdenum antimony spectrophotometric method.

[0062] After testing, the recovery rate of Na, K, N and P elements in human feces in this example is 70%....

Embodiment 3

[0070] A method for fecal heat treatment and recycling, including the following steps:

[0071] a) Add 40 g of cow dung with a water content of 95% to the reaction kettle, then seal the reaction kettle, and give an initial pressure of 0 MPa with gas.

[0072] b) Heat the reaction kettle to 220°C for 60 minutes, then stop heating.

[0073] c) Cool to room temperature, first connect a 2L gas bag to the gas outlet of the reactor to collect gas; then open the reactor to collect the remaining mixture; filter the remaining mixture to obtain an aqueous phase containing Na, K, and P elements and remaining substances .

[0074] The recovery rate of Na, K, N and P elements in the water phase was detected. Na and K elements were determined by inductively coupled plasma emission spectrometer; N and P elements were determined by potassium persulfate oxidation method and molybdenum antimony spectrophotometric method.

[0075] After testing, the recovery rate of the Na, K, N, and P elements in the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com