A kind of method for preparing propylene by catalytic cracking of n-butene

A catalytic cracking and n-butene technology, which is applied in chemical instruments and methods, hydrocarbon cracking to produce hydrocarbons, molecular sieve catalysts, etc., can solve the problems of low single-pass yield of the target product propylene and the need to further improve the propylene yield, and achieve high propylene The effect of one-way yield, increased holding capacity, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

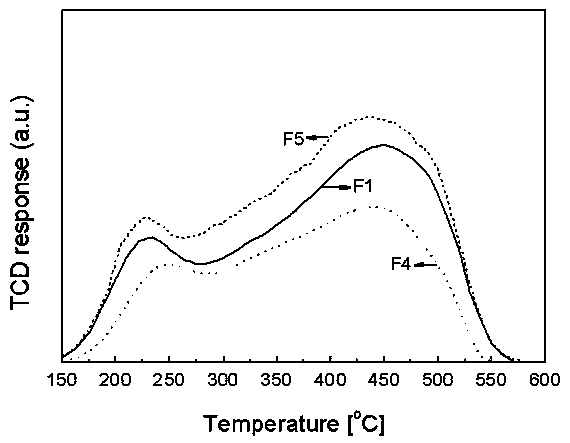

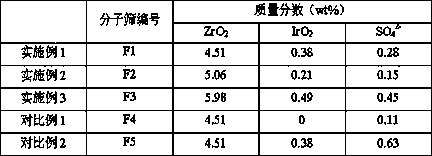

[0033] The specific preparation process of modified ZSM-5 molecular sieve F1 is as follows: (1) 8.5 g of zirconyl nitrate and 0.8 g of chloroiridic acid were dissolved in 22 ml of deionized water, and the obtained saline solution was added to 650 ml of n-hexane solvent, Stirring was continued for 1 hour to form a suspension A1. Add 114.5 g of Si / Al molar ratio 76, pore volume 0.19 cm to suspension A1 3 / g hydrogen ZSM-5 molecular sieve, stirred at room temperature (25°C) for 2 hours to obtain slurry B1. (2) Place the slurry B1 in a rotary evaporator, evaporate the n-hexane solvent to dryness, and obtain dry glue C1, dry at room temperature (25°C) for 24 hours, dry at 120°C for 12 hours, and then bake at 650°C for 5 hours, ZSM-5 molecular sieve D1 containing zirconium and iridium was obtained. (3) Transfer D1 into 500 ml of 0.1 mol / L ammonium sulfate solution and soak for 5 hours. After the required soaking time is reached, filter out the ammonium sulfate solution and rinse t...

Embodiment 2

[0037] The specific preparation process of modified ZSM-5 molecular sieve F2 is as follows: (1) 9.5 g of zirconyl nitrate and 0.5 g of chloroiridic acid were dissolved in 26 ml of deionized water, and the resulting saline solution was added to 520 ml of cyclohexane solvent , stirring continuously for 1 hour to form suspension A2. Add 113.0 g of Si / Al molar ratio 54, pore volume 0.23 cm to suspension A2 3 / g hydrogen ZSM-5 molecular sieve, stirred at room temperature (25°C) for 2 hours to obtain slurry B2. (2) Place the slurry B2 in a rotary evaporator and evaporate the cyclohexane solvent to obtain dry glue C2, dry it at room temperature (25°C) for 24 hours, dry it at 120°C for 12 hours, and then bake it at 600°C After 10 hours, ZSM-5 molecular sieve D2 containing zirconium and iridium was obtained. (3) Transfer D2 into 500 ml of 0.5 mol / L ammonium sulfate solution and soak for 1 hour. After the required soaking time is reached, filter out the ammonium sulfate solution and r...

Embodiment 3

[0039] The specific preparation process of modified ZSM-5 molecular sieve F3 is as follows: (1) 11.2 g of zirconyl nitrate and 1.1 g of chloroiridic acid were dissolved in 23.7 ml of deionized water, and the resulting saline solution was added to 950 ml of cyclohexane solvent , stirring continuously for 1 hour to form suspension A3. Add 114.5 g of Si / Al molar ratio 93, pore volume 0.21 cm to suspension A3 3 / g hydrogen ZSM-5 molecular sieve, stirred at room temperature (25°C) for 2 hours to obtain slurry B3. (2) Place the slurry B3 in a rotary evaporator and evaporate the cyclohexane solvent to obtain dry glue C3, dry at room temperature (25°C) for 24 hours, dry at 120°C for 12 hours, and then bake at 630°C After 10 hours, ZSM-5 molecular sieve D3 containing zirconium and iridium was obtained. (3) Transfer D3 into 500 ml of 0.3 mol / L sulfuric acid solution and soak for 3 hours. After the required soaking time is reached, filter out the sulfuric acid solution and rinse the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com