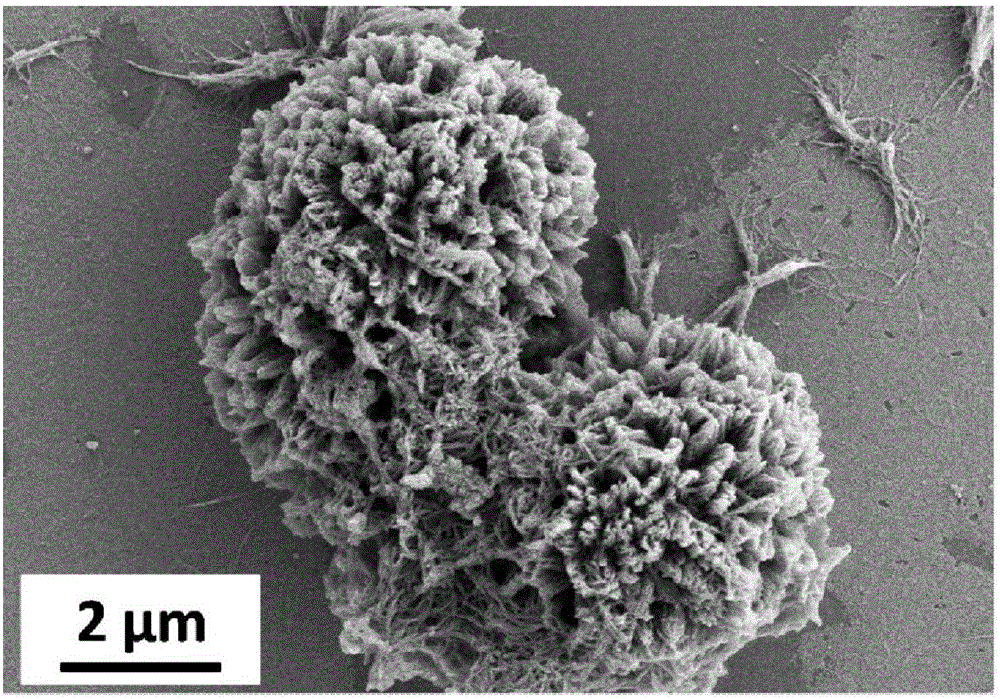

Flower-shaped porous polyaniline nanometer material and preparation method thereof

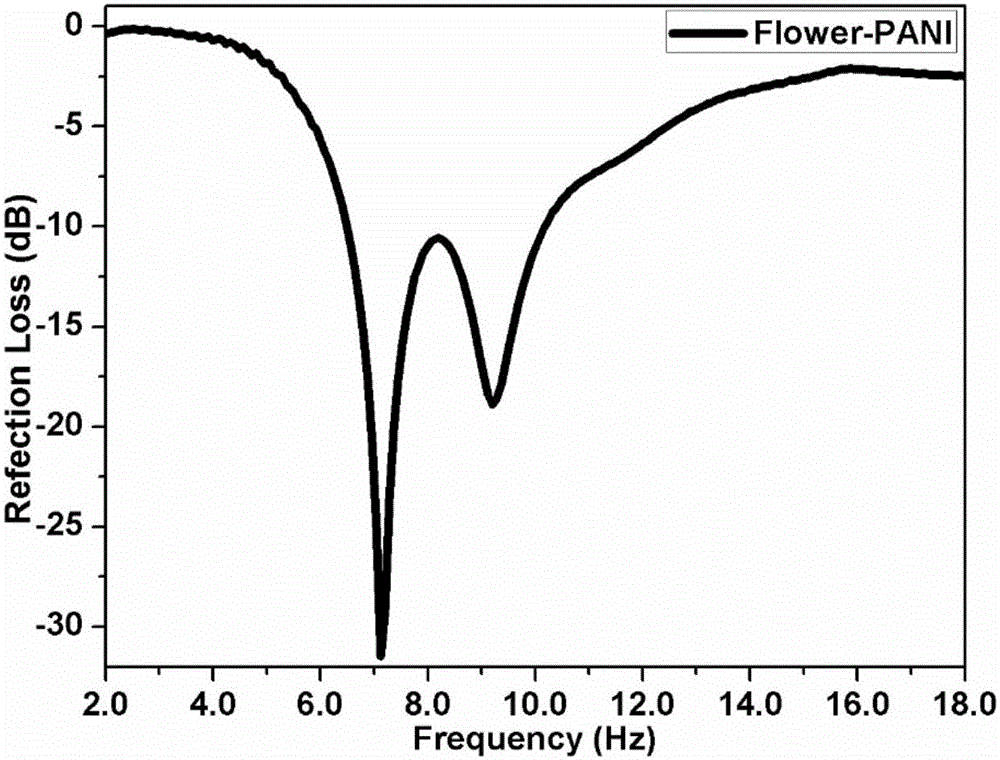

A nanomaterial and polyaniline technology, applied in the field of wave absorbing materials, can solve the problems of complicated steps of porous loose polyaniline composite material, unfavorable for industrial application and cost control, uneven molecular weight distribution of in-situ polymerization, etc. Multi-reflection effect, increasing electromagnetic wave receiving area, light specific gravity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing a flower-like porous polyaniline nanomaterial, comprising the steps of:

[0026] Step 1) adding L-phenylalanine into deionized aqueous solution for primary dispersion, then adding aniline monomer for secondary dispersion, magnetically stirring and mixing, then adding ammonium persulfate aqueous solution dropwise and stirring at a reduced speed to obtain a mixed reaction solution;

[0027] Step 2) leaving the mixed reaction solution to react at low temperature;

[0028] Step 3) After the reaction, thawing and suction filtration, washing and vacuum freeze-drying to obtain flower-like porous polyaniline nanomaterials.

[0029] In step 1), the molar ratio of L-phenylalanine and aniline monomer is 1-8:24. The molar ratio of L-phenylalanine, aniline monomer and ammonium persulfate is 1:3-24:4-30. The time for magnetic stirring and mixing is 10-60 minutes, and the speed of magnetic stirring and mixing is 100-300 rpm. The dropping rate of the ammonium ...

Embodiment 1

[0033] A preparation method of flower-like porous polyaniline nanomaterials, comprising the following steps:

[0034] 1) Disperse 0.179g of L-phenylalanine in 500ml of deionized water, and disperse evenly with magnetic stirring; then add 0.86g of aniline monomer, and use a low-temperature cooling system to keep the mixed solution at 5°C for 60 minutes with magnetic stirring; 2.34 Disperse 5 g of ammonium persulfate in 500ml of deionized water, cool down to 5°C for pre-cooling; add the ammonium persulfate solution dropwise to the mixed solution of L-phenylalanine and aniline, and control the reaction temperature at 5°C;

[0035] 2) After the dropwise addition, stop the magnetic stirring, take out the magnetic stirring bar, and continue to place the mixed solution system at -5°C for 5 hours of static reaction;

[0036] 3) Remove the supernatant from the product obtained in step 2) and suction filter, wash with deionized water and absolute ethanol until the filtrate is colorless;...

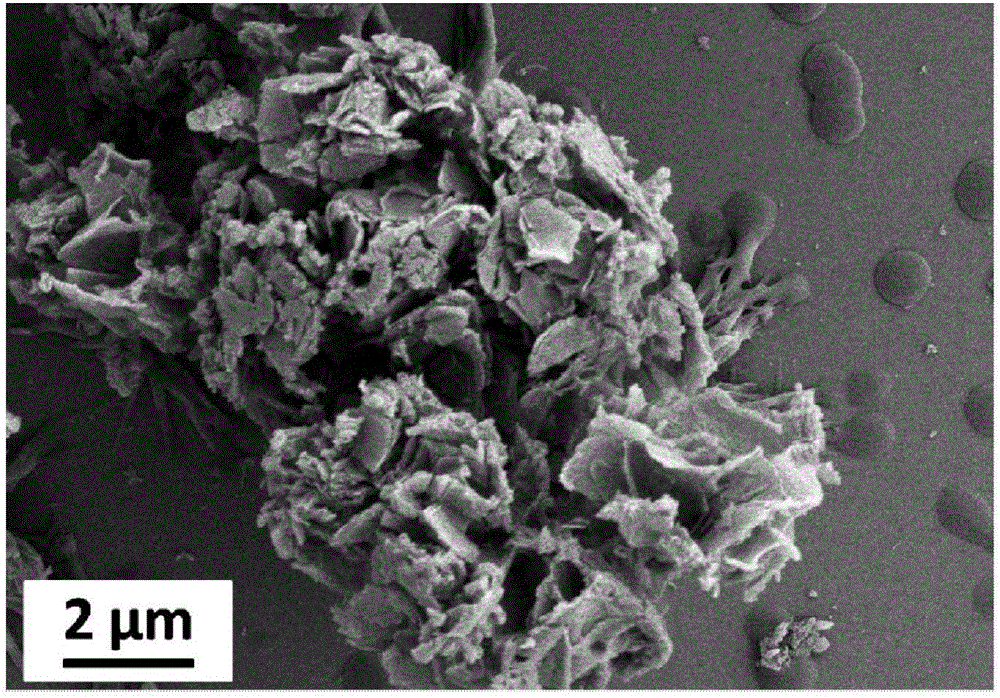

Embodiment 2

[0038] A preparation method of flower-like porous polyaniline nanomaterials, comprising the following steps:

[0039] 1) Disperse 0.269g of L-phenylalanine in 500ml of deionized water, and disperse evenly with magnetic stirring; then add 0.86g of aniline monomer, and use a low-temperature cooling system to keep the mixed solution at 5°C for 60 minutes; Disperse 5 g of ammonium persulfate in 500ml of deionized water, cool down to 5°C for pre-cooling; add the ammonium persulfate solution dropwise to the mixed solution of L-phenylalanine and aniline, and control the reaction temperature at 5°C;

[0040] 2) After the dropwise addition, stop the magnetic stirring, take out the magnetic stirring bar, and continue to place the mixed solution system at -5°C for 5 hours of static reaction;

[0041] 3) Remove the supernatant from the product obtained in step 2) and suction filter, wash with deionized water and absolute ethanol until the filtrate is colorless; then freeze at -10°C for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com