High-efficient instant slurry powder and preparation method thereof

An instant and mud technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high water loss, high cost, and more labor, so as to reduce water penetration, save economic costs, and reduce water loss. The effect of water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Application engineering: pile construction of a railway project in Shaanxi Province, the construction technology is rotary drilling and drilling, the pile length is about 50 meters, the pile diameter is 1 meter, and the geological conditions are silty sand layer below 20 meters.

[0024] The composition of the high-efficiency instant mud powder is shown in Table 1, and the application performance of the prepared mud is shown in Table 2.

[0025] Table 1 High-efficiency instant mud powder raw material composition (unit: part)

[0026] nonionic polyacrylamide Sodium starch grafted polyacrylate Potassium humate PAC 85 5 5 5

[0027] Table 2 prepared mud application performance

[0028] Viscosity (s) 30 Homogeneity time (h) 120 Sand concentration before the last cycle (%) 0.4 Number of cycles (times) 6 7.5min water loss (ml) 55 The longest wall stabilization time (h) 48

Embodiment 2

[0030] Application project: Pile construction of a railway project in Henan Province, the construction technology is rotary drilling, the pile length is about 50 meters, the pile diameter is 1.2 meters, and the geological condition is that the clay layer is below 10 meters.

[0031] The composition of the high-efficiency instant mud powder is shown in Table 3, and the application performance of the prepared mud is shown in Table 4.

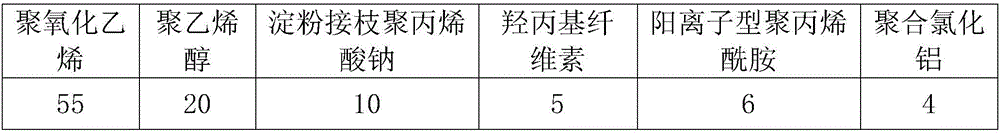

[0032] Table 3 High-efficiency instant mud powder raw material composition (unit: part)

[0033]

[0034] Table 4 prepared mud application properties

[0035] Viscosity (s) 21 Homogeneity time (h) 118 Sand concentration before the last cycle (%) 0.4 Number of cycles (times) 7 7.5min water loss (ml) 50 The longest wall stabilization time (h) 45

Embodiment 3

[0037] Application project: Pile construction of a railway project in Hunan Province, the construction technology is rotary drilling, the pile length is about 60 meters, the pile diameter is 1 meter, and the geological conditions are water-sensitive geology.

[0038] The composition of the high-efficiency instant mud powder is shown in Table 5, and the application performance of the prepared mud is shown in Table 6.

[0039] Table 5 The composition of high-efficiency instant mud powder raw materials (unit: part)

[0040] nonionic polyacrylamide polyethylene oxide Hydroxypropyl Cellulose Potassium humate PAC 30 40 15 5 15

[0041] Table 6 prepared mud application performance

[0042] Viscosity (s) 26 Homogeneity time (h) 115 Sand concentration before the last cycle (%) 0.5 Number of cycles (times) 8 7.5min water loss (ml) 30 The longest wall stabilization time (h) 42

[0043] It can be seen from Tables 2, 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com