Antifreezing water-based metal cutting fluid

A technology of metal cutting fluid and base type, applied in the field of metal cutting fluid and antifreeze water-based metal cutting fluid, can solve the problems of easy freezing or demulsification, unfavorable storage or transportation, etc. Good cooling and antifreeze performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

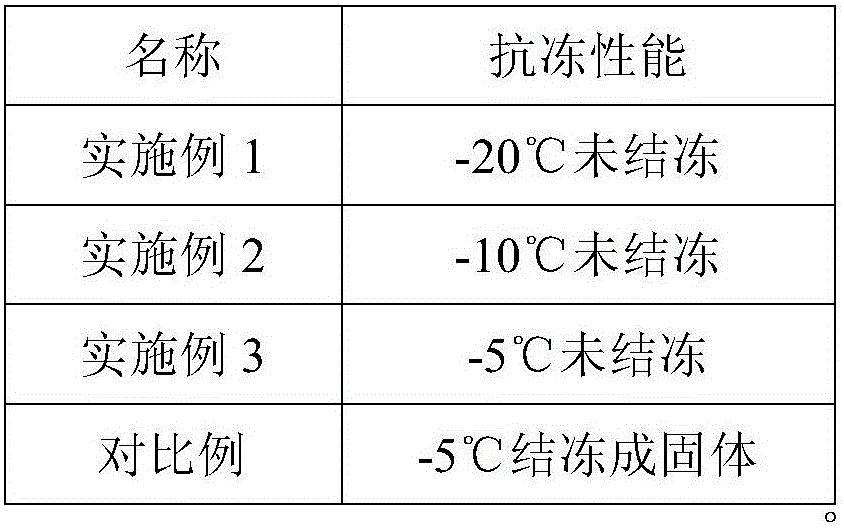

Examples

Embodiment 1

[0035] The microemulsion cutting fluid is composed of an oil additive and a water additive, the oil additive accounts for 49% of the total microemulsion cutting fluid; the water additive accounts for 28% of the total microemulsion cutting fluid, and the balance is water.

[0036] Oily additive A: 18% of mineral oil with a pour point less than -20 degrees, 8% of organic alcohol amine, 5% of organic carboxylic acid, 6.5% of sodium chloride stone, 4.5% of synthetic ester, 3.5% of sorbitan fatty acid ester, Petroleum sulfonate 3.5% mixed evenly and heated to 60-70 degrees Celsius, and kept warm for 30 minutes.

[0037] Mix 23% of water with 15% of ethylene glycol, 2% of nonylphenol polyoxyethylene ether, 1.5% of MBM, 0.7% of BK, 0.8% of ethylenediaminetetraacetic acid, 7.8% of water-based borate and defoamer (conventional Commercially available product) 0.2% mixed with water-based additive B, stirred and mixed evenly.

[0038] Then add the well-mixed liquid to the oily additive A...

Embodiment 2

[0040] The microemulsion cutting fluid is composed of an oily additive and a watery additive, the oily additive accounts for 40% of the total weight of the microemulsion cutting fluid; the water-based additive accounts for 26.2% of the total weight of the microemulsion cutting fluid, and the balance is water.

[0041] Oily additive A: 16% naphthenic oil with a pour point less than -20 degrees, 5% organic alcohol amine, 5% organic carboxylic acid, 8% phosphorus-containing extreme pressure agent, 2% synthetic ester, sorbitan fatty acid Ester 4% mixed evenly and heated to 60-70 degrees, and kept for 30 minutes.

[0042] Mix 33.8% of water with 10% of propylene glycol, 3% of octylphenol polyoxyethylene ether, 1.5% of sandan oil, 0.7% of BK, 0.8% of nitrilotriacetic acid, 10% of water-based borate and 0.2% of defoamer Mix the water-based additive B of the composition and stir and mix well.

[0043] Then add the well-mixed liquid to the oily additive A after the heat preservation i...

Embodiment 3

[0045] The microemulsion cutting fluid is composed of an oily additive and a watery additive, the oily additive accounts for 41% of the total weight of the microemulsion cutting fluid; the water-based additive accounts for 17% of the total weight of the microemulsion cutting fluid, and the balance is water.

[0046] Oil additive A: 10% naphthenic oil with a pour point less than -20 degrees, 8% organic alcohol amine, 5% organic carboxylic acid, 6.5% sulfur-containing extreme pressure agent, 4.5% synthetic ester, sorbitan fatty acid Mix 3.5% ester and 3.5% petroleum sulfonate evenly and heat to 60-70 degrees, and keep it warm for 30 minutes.

[0047] Mix water 42% with dipropylene glycol 5%, nonylphenol ethoxylate 2%, MBM 2%, IPBC 1%, EDTA 0.8%, sodium nitrite 6% and defoamer 0.2% Aqueous Additive B Stir and mix well.

[0048] Then add the well-mixed liquid to the oily additive A after the heat preservation is completed, and stir while adding, and finally form a transparent and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com