Production process for round aluminium alloy rod

A production process, technology of round aluminum rods, applied in the direction of metal/alloy conductors, conductive materials, conductive materials, etc., can solve problems such as low tensile strength, self-heavy weight, and large cable sag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

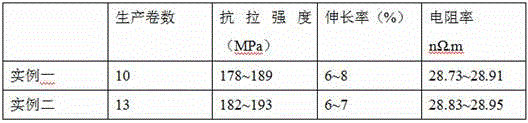

Embodiment 1

[0015] A production process of alloy round aluminum rods for electricians in this embodiment, the production process is continuous casting and rolling, and the specific steps are as follows:

[0016] (1) Fill the molten aluminum with an aluminum content of more than 99.60% in the smelting furnace according to the production demand, so that the temperature is controlled at 748°C;

[0017] (2) 1kg of industrial silicon, 5kg of iron agent with 75% iron content and 3kg of copper agent with 75% copper content are added per ton of aluminum;

[0018] (3) After standing for 15 minutes, add 3 kg of rare earth alloy and 4.5 kg of aluminum boron alloy per ton of aluminum, the rare earth includes lanthanum La and cerium Ce;

[0019] (4) Control the temperature in the furnace at 739°C, turn on electromagnetic stirring to stir the aluminum alloy melt for 38 minutes;

[0020] (5) After the sampling analysis meets the requirements of the alloy standard, use 0.1~0.2MPa argon spray powder (ref...

Embodiment 2

[0025] A production process of alloy round aluminum rods for electricians in this embodiment, the production process is continuous casting and rolling, and the specific steps are as follows:

[0026] (1) Fill the molten aluminum with an aluminum content of more than 99.60% according to the production demand in the smelting furnace, so that the temperature is controlled at 760°C;

[0027] (2) 1kg of industrial silicon, 5kg of iron agent with 75% iron content and 3kg of copper agent with 75% copper content are added per ton of aluminum;

[0028] (3) After standing for 19 minutes, add 3kg of rare earth alloy and 4.5kg of aluminum boron alloy per ton of aluminum, the rare earth includes lanthanum La and cerium Ce;

[0029] (4) Control the temperature in the furnace at 756°C, and turn on the electromagnetic stirring to stir the aluminum alloy melt for 40 minutes;

[0030] (5) After the sampling analysis meets the requirements of the alloy standard, use 0.1~0.2MPa argon spray powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com