Structure of membrane electrode for SPE water electrolysis and preparation and application thereof

A water electrolysis and membrane electrode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of low catalyst utilization, high catalyst dosage, poor electrode stability, etc., and achieve adjustable catalyst components and thin catalytic layer thickness , the effect of enhancing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

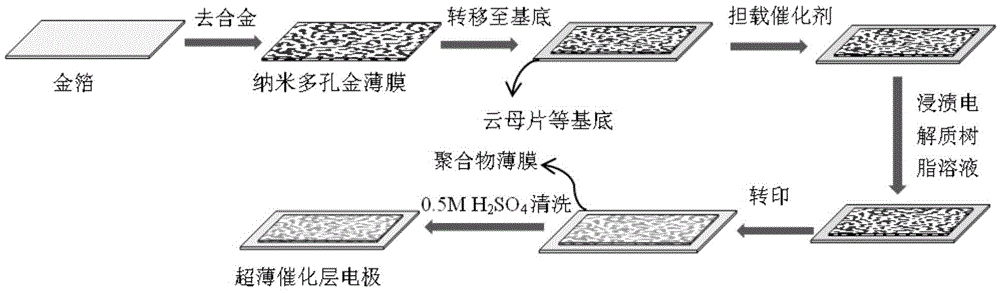

Embodiment 1

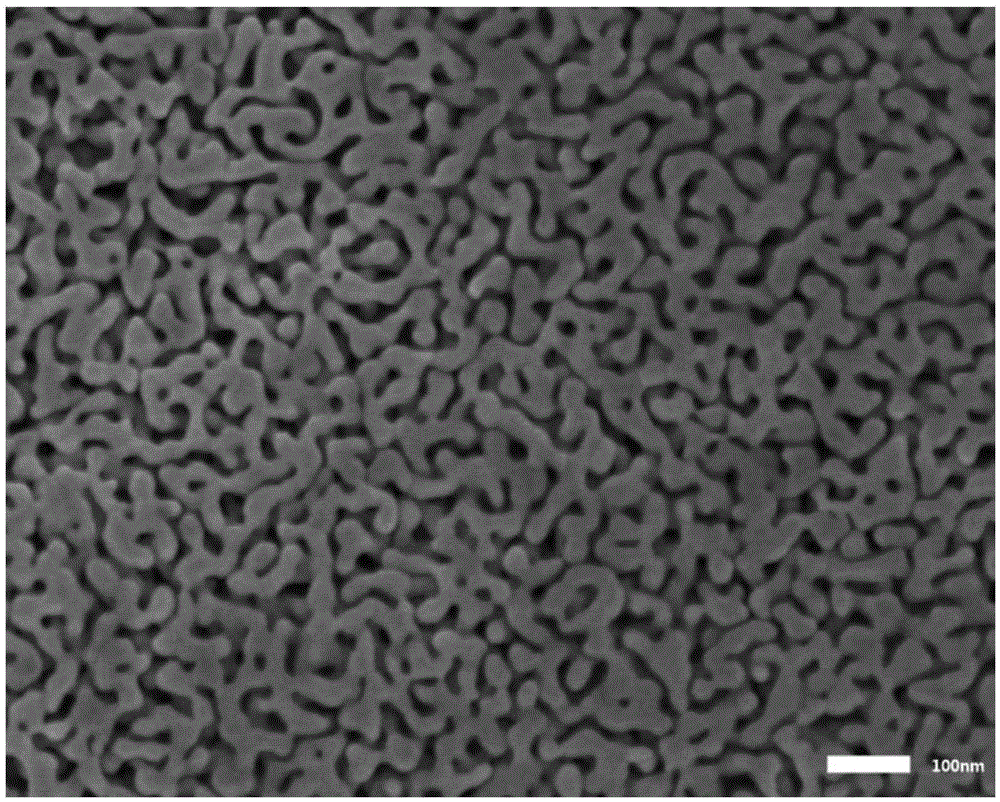

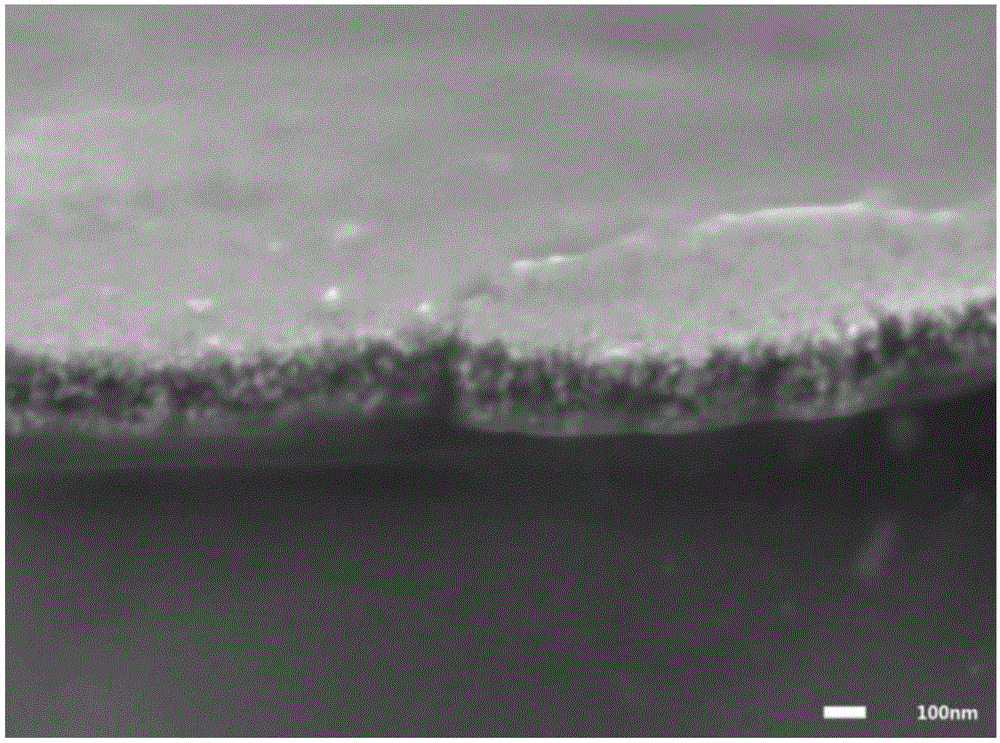

[0051] With 12K gold leaf (Au 50 Ag 50 wt.%) as the raw material, cut the gold foil into 2.1cm*2.1cm, spread the gold foil on the surface of deionized water, and transfer it to the nitric acid aqueous solution (the volume ratio of nitric acid and deionized water is 1:1), control The reaction time is 2 hours, and the reaction temperature is controlled at 25°C. Transfer the nanoporous gold film (NPG, nanoporous gold film) obtained after dealloying to deionized water, at this time, the nanoporous gold film spreads on the surface of deionized water; replace the deionized water 3-4 times to remove the nanoporous gold film. nitric acid on the gold film; the nanoporous gold film was transferred to a mica sheet (size 2.5cm*7.0cm), and dried at room temperature; the prepared nanoporous gold was labeled as NPG. The SEM section test shows that the prepared nanoporous gold has a thickness of 150nm; the pore size test shows that the porosity is 59.92%, and the characteristic pore size is...

Embodiment 2

[0062] Refer to Example 1 for the preparation and transfer process of the nanoporous gold film.

[0063] Prepare H at a concentration of 0.05M 2 IrCl 6 isopropanol solution, impregnate the NPG loaded on the mica sheet into the prepared H 2 IrCl 6 In the isopropanol solution, control the immersion time to 3.0min and the immersion temperature to 25°C. After the impregnation was completed, the mica sheet was taken out, the remaining precursor solution on the surface was sucked off, and the impregnated NPG was dried at room temperature.

[0064] The NPG impregnated with the catalyst precursor was placed in a tube furnace and calcined at 400 °C, 450 °C, and 500 °C for 30 min to prepare the catalytic layer, and the roasting atmosphere was air.

[0065] Reheat pressed on 212 (DuPont) membrane, the transfer pressure was 2.0MPa, the time was 30s, and the mica substrate was removed after transfer.

[0066] The electrodes prepared by firing at 400°C, 450°C, and 500°C are marked as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com