A method of injecting foamy air and oxygen-enriched pyrolysis thermochemical composite air flooding into the oil layer

An air flooding and foam technology, applied in chemical instruments and methods, mining fluids, earthwork drilling, etc., can solve the problems of poor foam stability, hindering popularization and application, short half-life of foam fluid, etc., and achieves short reaction period and high cracking temperature. , The effect of high oil recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

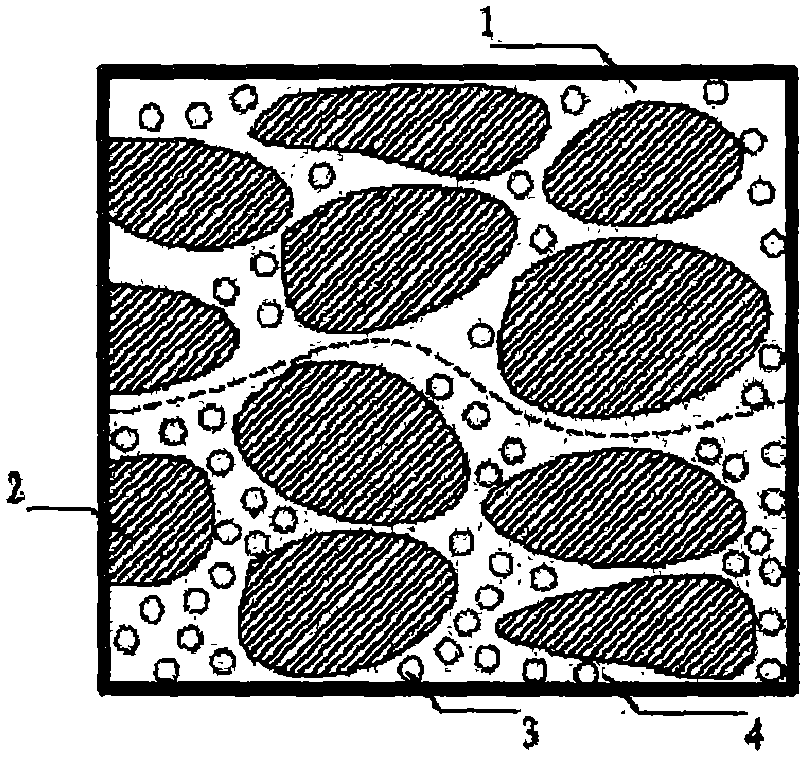

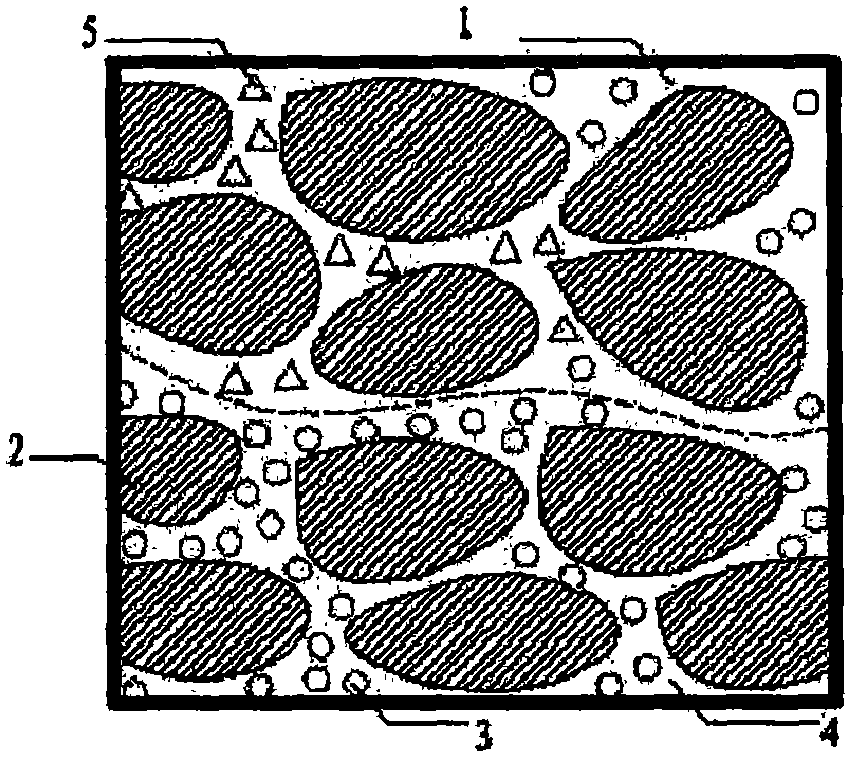

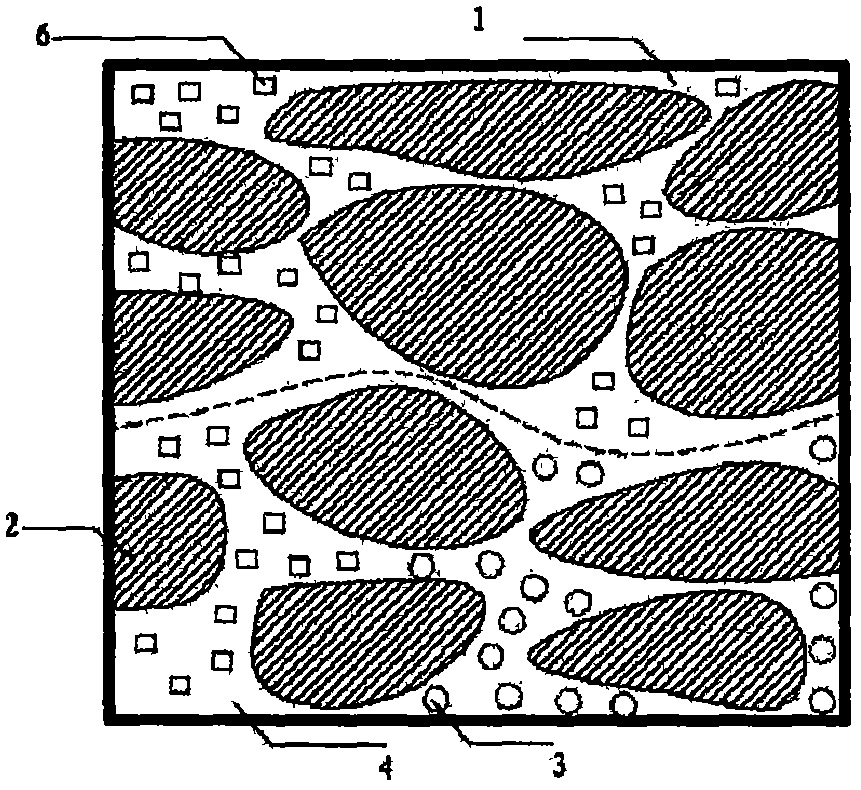

[0041]Injecting foamy air and oxygen-enriched pyrolysis composite air flooding oil recovery method into the oil layer:

[0042] 1. Foam injection stage: Mix the foaming agent and water evenly to prepare a foam solution. The foaming agent must be avoided during the mixing process, and the foam solution is injected into the formation through the gas injection well. After the foam solution is injected, air is injected, and the foam starts to foam during the process of pushing the foam solution into the cracks of the oil layer, and the cracks and pores in the oil layer are blocked. The concrete composition of foam solution and percentage mass ratio in the aqueous solution are: sulfonate dioctyl succinate sodium sulfonate 3.5% and dodecylbenzene sodium sulfonate 5%, thickener 6501 (coconut oil fatty acid Diethanolamide) 5%, chelating agent sodium silicate 1.5%, sacrificial agent hydroxysuccinic acid 2%, alcohols ethylene glycol 1.5%, and the balance is clear water.

[0043] 2. Oxy...

Embodiment 2

[0046] Compared with Example 1, the difference is that the specific composition of the foam solution in step 1 and the percentage mass ratio in the aqueous solution are: sulfonate dioctylsuccinate sodium sulfonate 3.2% and dodecylbenzenesulfonic acid Sodium 4.5%, thickener 6501 (coconut oil fatty acid diethanolamide) 4.5%, chelating agent sodium silicate 1.2%, sacrificial agent hydroxysuccinic acid 1.5%, alcohol ethylene glycol 1.2%, and the balance is clear water.

Embodiment 3

[0048] Compared with Example 1, the difference is that the specific components of the foam solution in step 1 and the percentage mass ratio in the aqueous solution are: sulfonate dioctylsuccinate sodium sulfonate 3.8% and dodecylbenzenesulfonic acid Sodium 5.5%, thickener 6501 (coconut oil fatty acid diethanolamide) 5.6%, chelating agent sodium silicate 1.9%, sacrificial agent hydroxysuccinic acid 2.6%, alcohol ethylene glycol 1.8%, and the balance is clear water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com