Platinum-iridium alloy type ignition electric nozzle for aero-engine

An aero-engine and platinum-iridium alloy technology, which is applied in the direction of machines/engines, mechanical equipment, gas turbine devices, etc., can solve the problems of corrosion and deformation of the center electrode of the ignition nozzle, hidden dangers of the engine ignition system and engine safety, and improve the anti-oxidation performance , saving economic cost, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

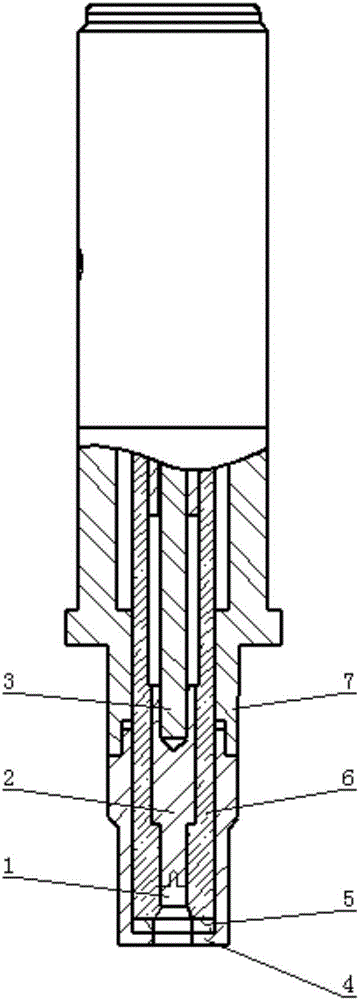

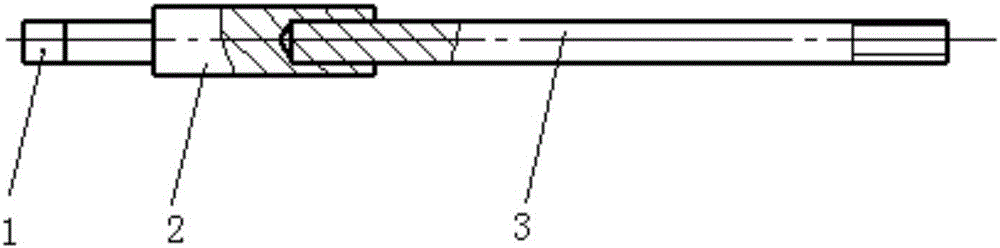

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] see figure 1 . In the structural diagram of the ignition nozzle in the figure, there are center electrode 1 , electrode 2 , sealing wire 3 , side electrode 4 , shell 5 , porcelain tube 6 , and shell 7 . Since the ignition nozzle is used in a high-temperature and high-pressure environment and is also subject to fuel corrosion, the requirements for the electrode material are very high, so the platinum-iridium alloy material with strong oxidation resistance and corrosion resistance is selected. Because 95% alumina ceramics has a high dielectric constant and anti-corona performance, the inner porcelain tube 6 mainly relies on 95% alumina ceramics as an insulating medium. The high temperature glass glue is filled in the rear end of the porcelain tube 6 and the shell 7, and the internal parts of the product are sintered into one body to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com