Non-woven cloth oven integrating infrared drying and water circulation cooling and drying system

A technology of water circulation cooling and non-woven fabrics, applied in drying, dryer, progressive dryer and other directions, can solve problems such as high energy consumption, damage, non-woven fabric breakage, etc., to achieve low energy consumption, avoid damage or Fracture, uniform cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

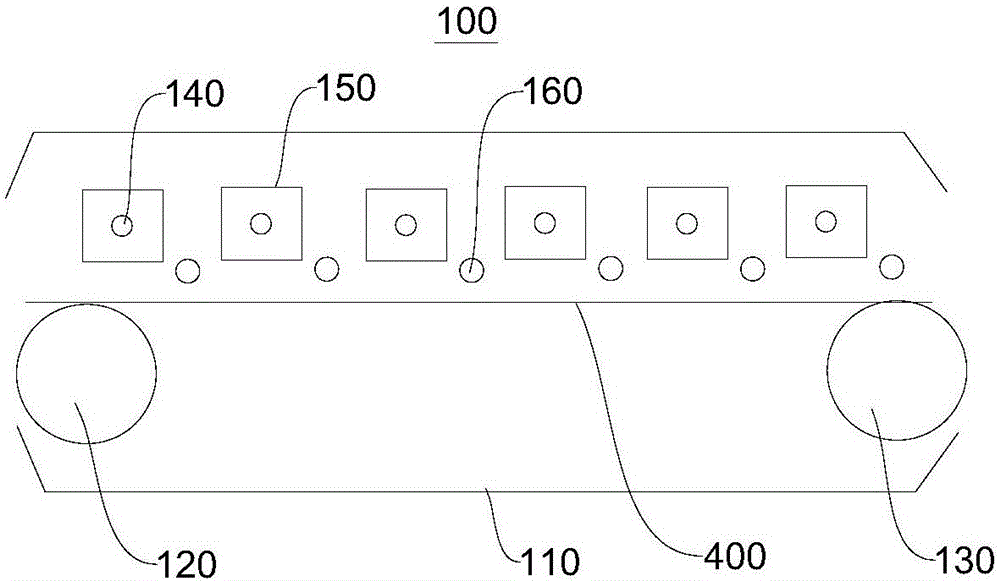

[0032] figure 1 For the schematic structural diagram of the nonwoven fabric oven 100 integrating infrared drying and water circulation cooling provided in the first embodiment of the present invention, please refer to figure 1 .

[0033] This embodiment provides a nonwoven fabric oven 100 integrating infrared drying and water circulation cooling. The nonwoven fabric oven 100 integrating infrared drying and water circulation cooling is used for drying the nonwoven fabric 400 . The nonwoven fabric oven 100 integrating infrared drying and water circulation cooling includes a box body 110, a first idler roller 120, a second idler roller 130, a temperature controller (not shown in the figure), and a plurality of infrared tubes 140, a plurality of cooling tubes 160, a water pump (not shown) and a plurality of quartz boxes 150.

[0034] The first idler 120 , the second idler 130 , the infrared tube 140 and the cooling tube 160 are all arranged inside the box body 110 . The first ...

no. 2 example

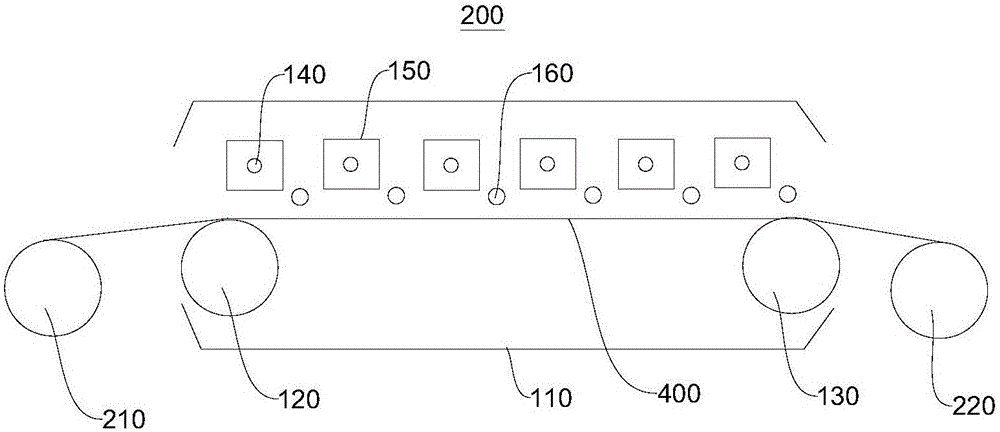

[0042] figure 2 For the structure diagram of the nonwoven fabric drying system 200 integrating infrared drying and water circulation cooling provided for the second embodiment of the present invention, please refer to figure 2 .

[0043] This embodiment provides a nonwoven fabric drying system 200 integrating infrared drying and water circulation cooling. The nonwoven fabric drying system 200 integrating infrared drying and water circulation cooling includes a supply roll 210, a take-up roll 220 and the nonwoven fabric oven 100 integrating infrared drying and water circulation cooling in the first embodiment.

[0044] The supply roller 210 is arranged on one side of the nonwoven fabric oven 100 integrating infrared drying and water circulation cooling, and the supply roller 210 is used to transport the nonwoven fabric 400 to the first idler roller 120 . The take-up roller 220 is arranged on the other side of the nonwoven fabric oven 100 integrating infrared drying and wate...

no. 3 example

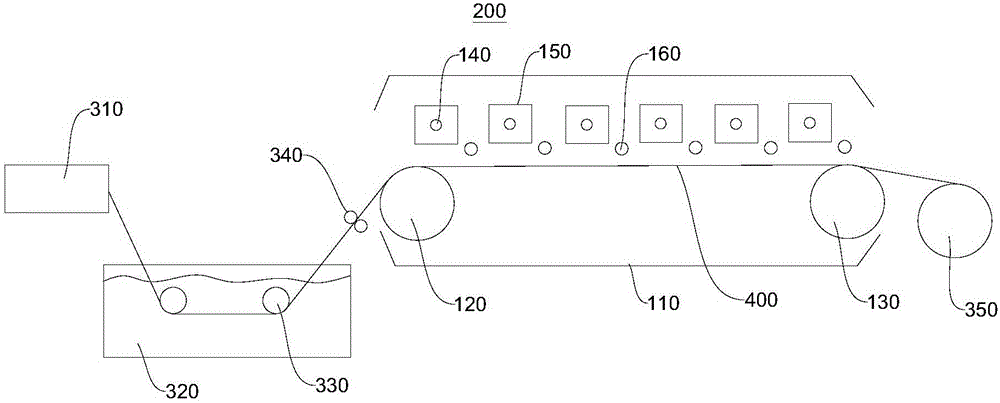

[0048] image 3 For the structure diagram of the nonwoven fabric drying system 200 integrating infrared drying and water circulation cooling provided by the third embodiment of the present invention, please refer to image 3 .

[0049] This embodiment provides a nonwoven fabric drying system 200 integrating infrared drying and water circulation cooling. The nonwoven fabric drying system 200 integrating infrared drying and water circulation cooling includes a nonwoven fabric forming machine 310, a cooling tank 320, a positioning roller 330, a guide roller 340, a winding roller 350 and the infrared drying and water circulation in the first embodiment. Cooled nonwovens oven 100.

[0050] The nonwoven fabric forming machine 310 is arranged on the side of the nonwoven fabric oven 100 that integrates infrared drying and water circulation cooling relatively close to the first idler roller 120 . The cooling tank 320 is arranged between the nonwoven fabric forming machine 310 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com