Multispectral infrared filter array based on micro nano grating

An infrared filter and multi-spectral technology, which is applied in the field of multi-spectral infrared filter arrays, can solve the problems of low transmittance, poor suppression of sideband values, wide bandwidth, etc., and achieve simple manufacturing process, simple structure and accurate high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

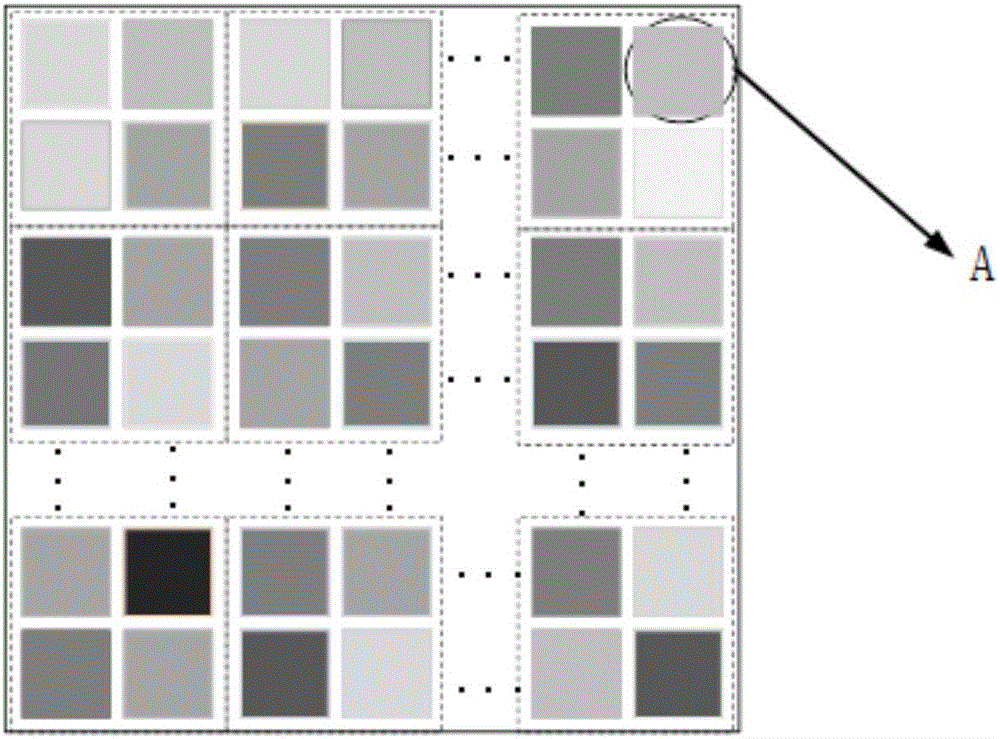

[0025] The invention discloses a multi-spectral infrared filter array based on a micro-nano grating, such as figure 1 , figure 2 As shown, including multiple grating filters arranged in a mosaic pattern, figure 1 Since the parameters of each filter are different, each filter has a different color depth and can obtain different light requirements. The structure of each grating filter is a two-dimensional metal grating from top to bottom. Layer and base structure layer, due to the structural symmetry of the two-dimensional metal grating, the transmission peak wavelength is independent of the polarization direction of the incident light, which greatly improves the utilization efficiency of the incident light in the absorbance detection process.

[0026] Based on the dispersion properties of aluminum and gold in the near-infrared band, the material of the two-dimensional metal grating layer is metal gold; because of the high transmittance and low refractive index of fused silica...

Embodiment 2

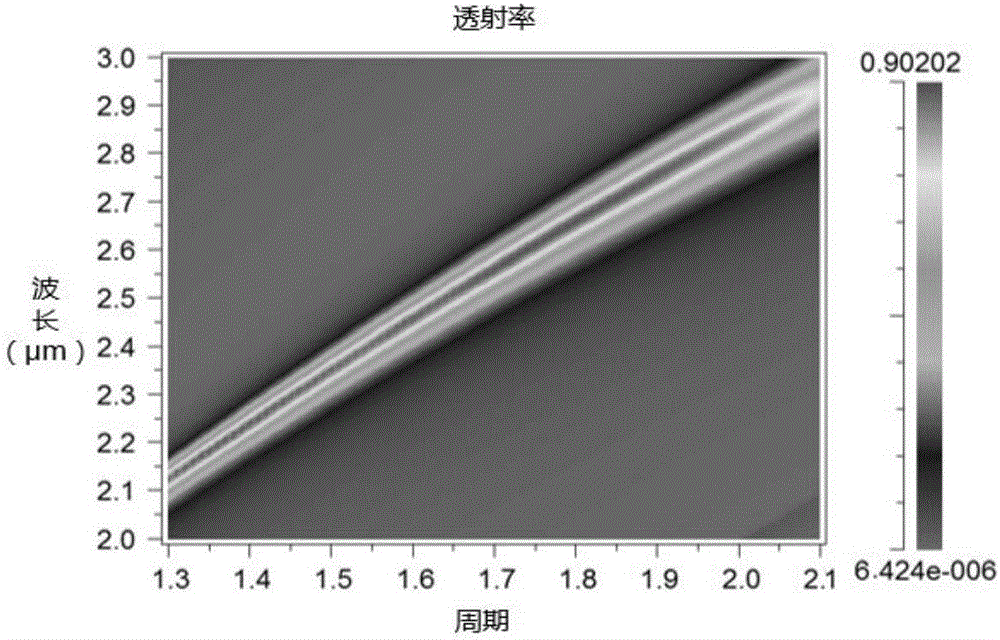

[0039] In the near-infrared 3.0-3.8μm band, when the grating period P is 2.1μm-3.0μm, the grating groove depth h1 is 0.06μm-0.15μm, the duty cycle f is 0.8-0.92, and the thickness of the base structure layer h=0.4-0.7μm , through multivariate optimization of the objective function, the effect of the grating period P on the transmittance, that is, the effect on the central wavelength and bandwidth, can be obtained, namely Figure 5 shown.

[0040] Depend on Figure 5It can be seen that the spectral curve of the grating filter has a narrow bandwidth of 20-100nm, a high transmittance of 96%, and a low sideband transmittance of less than 0.01%, which almost meets the requirements of the ideal spectral curve. However, to obtain a fixed bandwidth spectral curve, it needs to be adjusted. Other parameters, combined to obtain the optimal spectral curve, such as increasing the duty cycle f can reduce the bandwidth width, but move the central wavelength and reduce the central wavelength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com