A p-gan/i-gan/n-bn neutron detector

A neutron detector and p-gan technology, applied in the field of nuclear radiation detection, can solve the problems of neutron conversion layer and low detection efficiency, and achieve the effects of low cost, improved detection efficiency and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

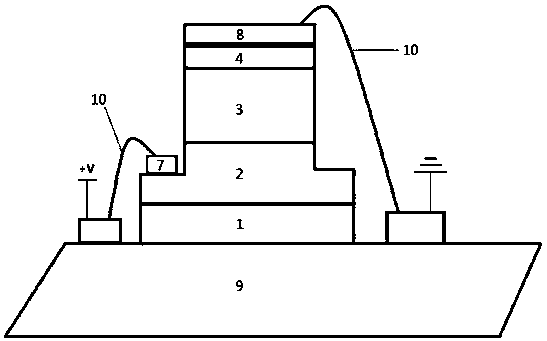

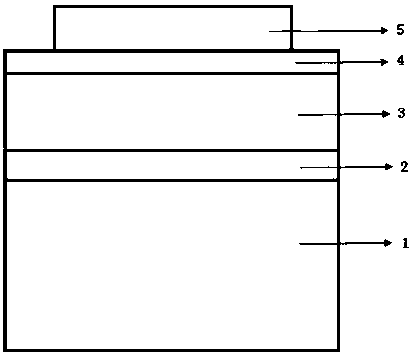

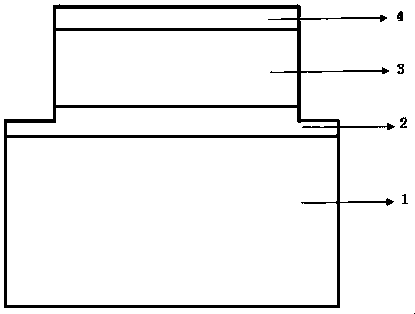

[0032] The p-GaN / i-GaN / n-BN neutron detector of the present invention and its preparation method, the detector is suitable for detecting low-energy thermal neutrons:

[0033] First, 150 μm thick Al 2 o 3 The substrate 1 is placed in the growth chamber of the metal-organic chemical vapor deposition equipment, and then the Al 2 o 3 The substrate 1 is heated to 1100° C. and baked at high temperature for 10 minutes to remove impurities on the surface of the substrate. First grow a GaN buffer layer with a thickness of 20nm at 550°C, then raise the temperature to 1350°C to grow n-BN thin film 2, hydrogen sulfide is used as the gas doping source, and the doping concentration is 5×10 18 cm -3 , with a thickness of 20 μm; again at a temperature of 1050 ° C, epitaxially grow an undoped i-GaN film 3 on the n-BN film 2 with a thickness of 10 μm; finally at a temperature of 950 ° C, on the n-GaN / i -GaN film epitaxial growth p-GaN film 4 ( figure 2 ), magnesium dicene as the gas dopi...

Embodiment 2

[0039] The preparation method of the neutron detector with p-GaN / i-GaN / n-BN structure of the present invention, the detector is suitable for detecting fast neutrons with an energy of 0.1-5 MeV, and a polyethylene switch is placed between the neutron source and the detector agent:

[0040] First, a 200 μm thick Al 2 o 3 The substrate 1 is placed in the growth chamber of the metal-organic chemical vapor deposition equipment, and then the Al 2 o 3 The substrate 1 is heated to 1100° C. and baked at high temperature for 10 minutes to remove impurities on the surface of the substrate. First grow a GaN buffer layer with a thickness of 20nm at 550°C, then raise the temperature to 1400°C to grow n-BN film 2, hydrogen sulfide is used as the gas doping source, and the doping concentration is 6×10 18 cm -3 , with a thickness of 30 μm; again at a temperature of 1050 ° C, epitaxially grow an undoped i-GaN film 3 on the n-BN film 2 with a thickness of 15 μm; finally at a temperature of ...

Embodiment 3

[0046] The preparation method of the neutron detector with p-GaN / i-GaN / n-BN structure of the present invention, the detector is suitable for detecting fast neutrons with an energy of 0.1-10 MeV, and a polyethylene switch is placed between the neutron source and the detector agent:

[0047] First, 150 μm thick Al 2 o 3 The substrate 1 is placed in the growth chamber of the metal-organic chemical vapor deposition equipment, and then the Al 2 o 3The substrate 1 is heated to 1100° C. and baked at high temperature for 10 minutes to remove impurities on the surface of the substrate. First grow a GaN buffer layer with a thickness of 20nm at 550°C, and then raise the temperature to 1500°C to grow n-BN thin film 2, hydrogen sulfide is used as the gas doping source, and the doping concentration is 8×10 18 cm -3 , with a thickness of 50 μm; again at a temperature of 1050 ° C, epitaxially grow an undoped i-GaN film 3 on the n-BN film 2 with a thickness of 20 μm; finally at a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com