Method for preparing chicken flavoring from waste beer yeast

A technology of waste beer yeast and chicken essence, applied in the field of preparation of chicken essence by waste beer yeast, to achieve delicious taste, reduce production cost, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

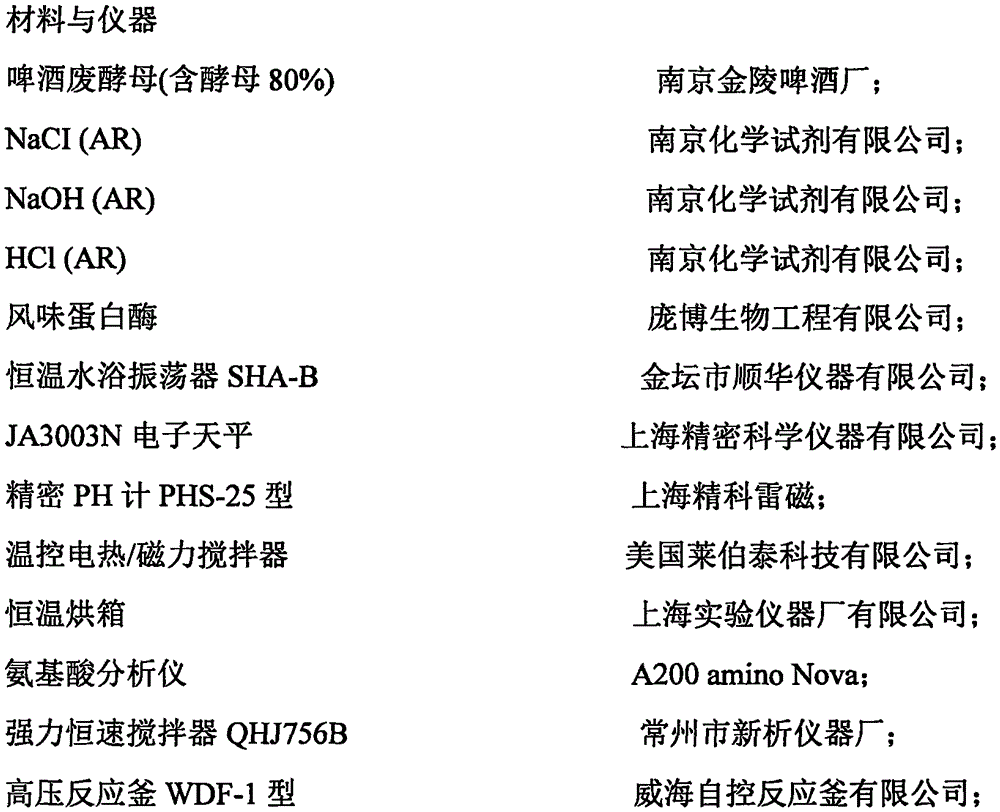

Method used

Image

Examples

Embodiment 1

[0015] Mix the waste beer yeast with water, sieve twice with a 120-mesh sieve, centrifuge at 5000r / min, wash by centrifugation for 3 times, collect the yeast sludge obtained by centrifugation; put the obtained yeast sludge into a container, add water and stir evenly , make yeast suspension, add NaCl, adjust the pH value to 6.0 with NaOH and HCl, add 1.2% flavor protease of yeast slime mass to the yeast suspension, and enzymolyze at 50°C for 24h; after enzymolysis, heat up to Inactivate the enzyme at 80°C for 20 minutes, then centrifuge at 5000r / min, collect the supernatant, and obtain the yeast protein hydrolyzate.

[0016] Get yeast enzymolysis liquid and water and be made into 100g solution, add 4g glucose, 1g cysteine, 1g glycine, 1.5g thiamine, 4g chicken fat to it, then add in high-pressure reactor and carry out Maillard reaction, reaction The temperature is 120° C., the reaction time is 50 minutes, and the pH value is 6.0. After the reaction is completed, pass condensed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com