Method and system for processing cut stems for fine cigarettes

A processing method and technology for cut stems, which are applied in the field of processing methods and systems for cut cut stems for thin cigarettes, can solve the problems of destroying fibrous tissue cells of tobacco stems, affecting the sensory quality of cigarettes, and large investment in equipment, so as to reduce technological updates. Cost and risk, good versatility and compatibility, and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

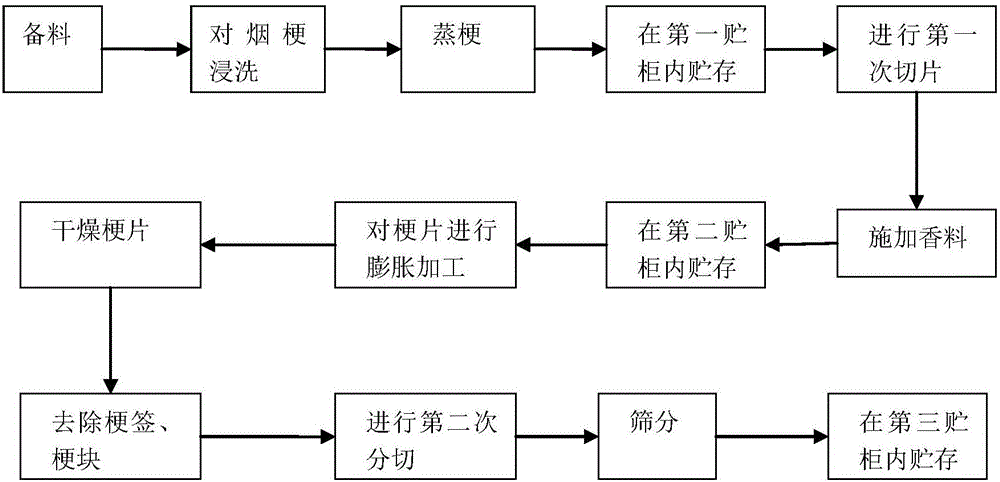

[0066] Such as figure 1 Shown, a kind of processing method of shredded stem for thin cigarette, concrete steps are as follows:

[0067] 1) The tobacco stems are soaked with a soaking machine, and the tobacco stems are soaked with water at 60±5°C. The soaking time is 60-150s, and the flow rate of the tobacco stems is 2600-3200kg / h. Moisture at 25-31%;

[0068] 2) After washing the tobacco stems, steam the stems to loosen the tissue, increase softness and resistance to crushing, and then store the stems. The process parameters are controlled as follows:

[0069] project unit skills requirement steam pressure MPa 0.5-0.8 Tobacco stem moisture after steaming % 32-38 Discharge temperature ℃ 85-90 Storage time h 2-48

[0070] 3) Slitting the stored tobacco stems into stem slices with a thickness meeting the technical requirements, the thickness of the cut stem slices: 0.16-0.22 mm.

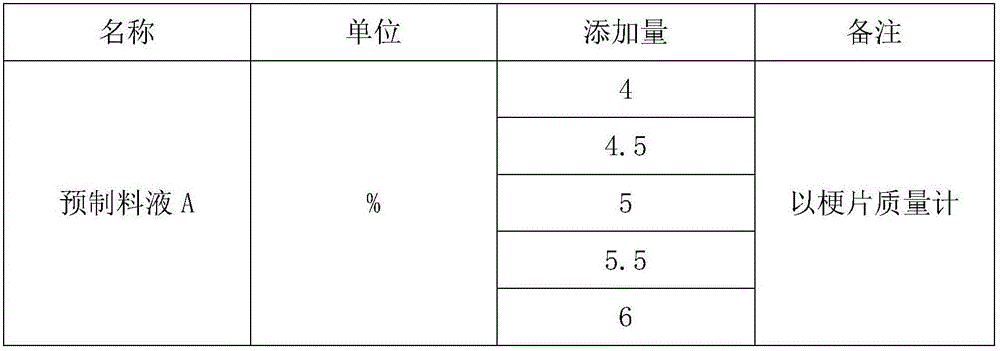

[0071] 4) Add prefabricated feed liquid A to the s...

Embodiment 2

[0093] 1) Obtain quantitative tobacco stems, wash with water to remove tobacco powder and non-tobacco impurities, and each process parameter is controlled as follows:

[0094] project unit skills requirement washing time s 60-150 washing water temperature ℃ 40-70 stem flow kg / h 2600-3200 Tobacco stem moisture after washing % 25-31

[0095] 2) After washing the tobacco stems, steam the stems to loosen the tissue, increase softness and resistance to crushing, and then store the stems. The process parameters are controlled as follows:

[0096] project unit skills requirement steam pressure MPa 0.5-0.8 Tobacco stem moisture after steaming % 32-38 Discharge temperature ℃ 85-90 Storage time h 2-48

[0097] 3) Mechanically press the tobacco stems whose water content meets the process requirements to the thickness required by the process, and the thickness is 1.0-1.6mm.

[0098] 4) Slitting ...

Embodiment 3

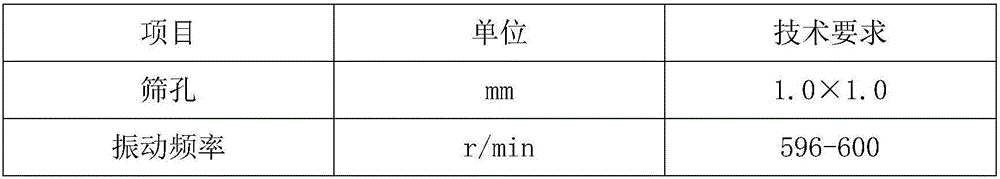

[0116]A processing system for shredded cigarette stems, including a stem dipping machine for rinsing tobacco stems, a tobacco stem moisturising machine that provides a steam pressure of 0.5-0.8MPa, a first storage cabinet, a first cutting device, and a feeding device , the second storage cabinet, providing a cut stem expander with a steam pressure of 0.4-0.8MPa, a shred drying machine for drying stem slices, a cut stem air separator for sorting stem sticks and stem pieces in stem slices, The second cutting equipment, cut stem screening machine, the above equipments are connected through the conveying equipment in turn, or set up independently, the conveying mechanism can be a belt conveyor or a vibrating conveyor, after the cut stems are screened, the The shredded stems are sent into the third storage cabinet for storage.

[0117] The above-mentioned processing system shows how the cut stems are processed in each equipment, the work efficiency is high, the obtained cut stems m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com