Method for separating and recycling organic solvent from dregs evaporation tail gas

A technology of separation and recovery and organic solvent, which is applied in the field of separation and recovery of organic solvent in the tail gas of dregs distillation, can solve the problems of crushing, pulverization, limiting the popularization and application of resin adsorption technology, increasing equipment investment and the amount of adsorption resin used, etc. broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

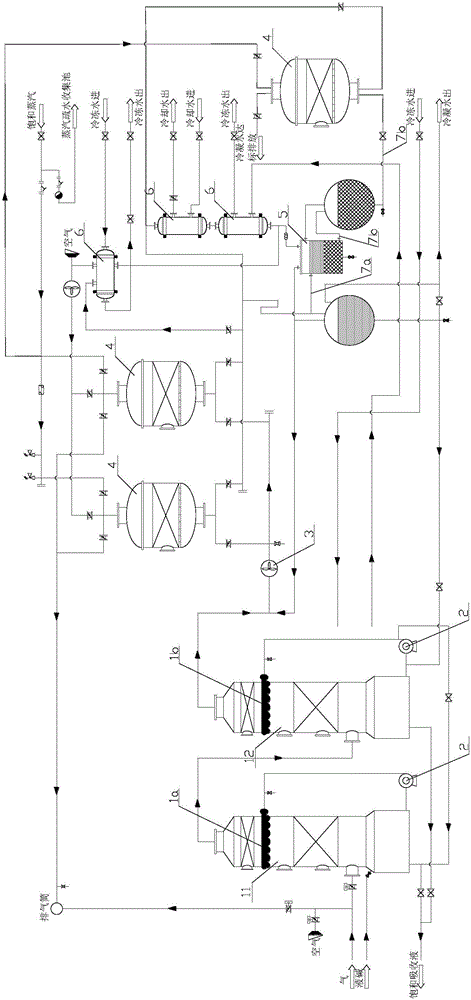

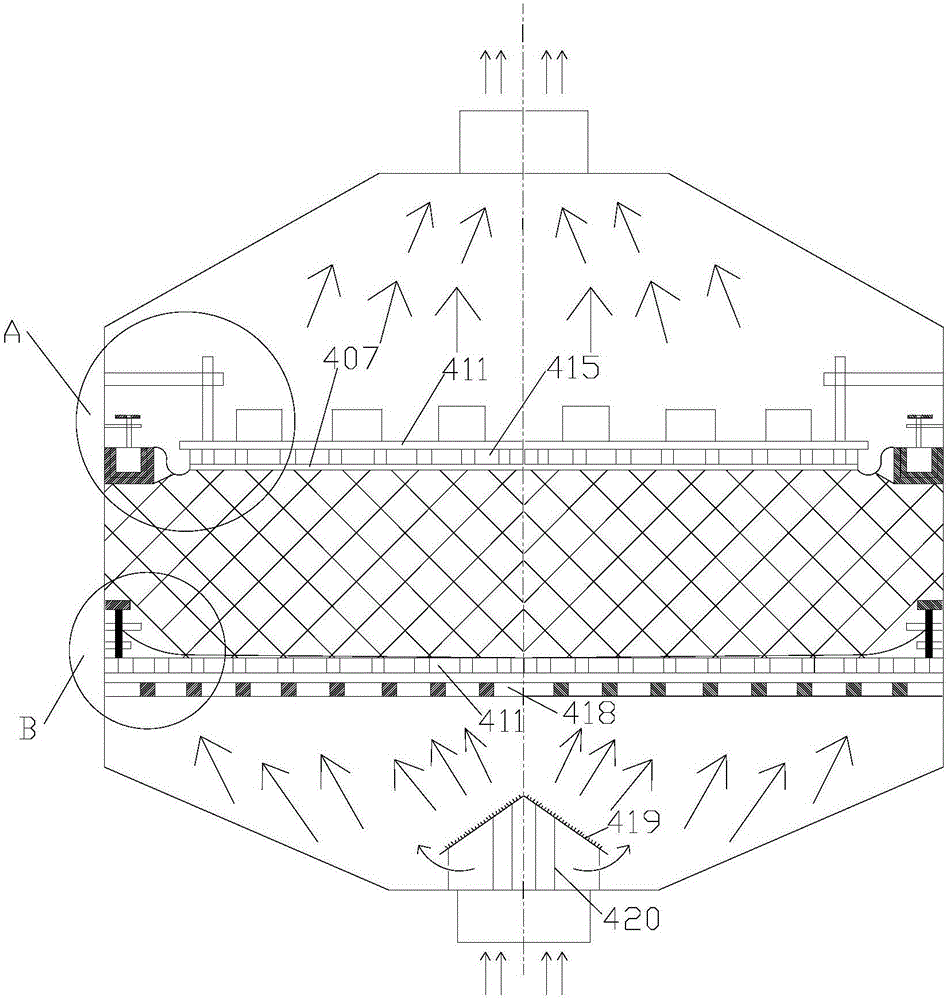

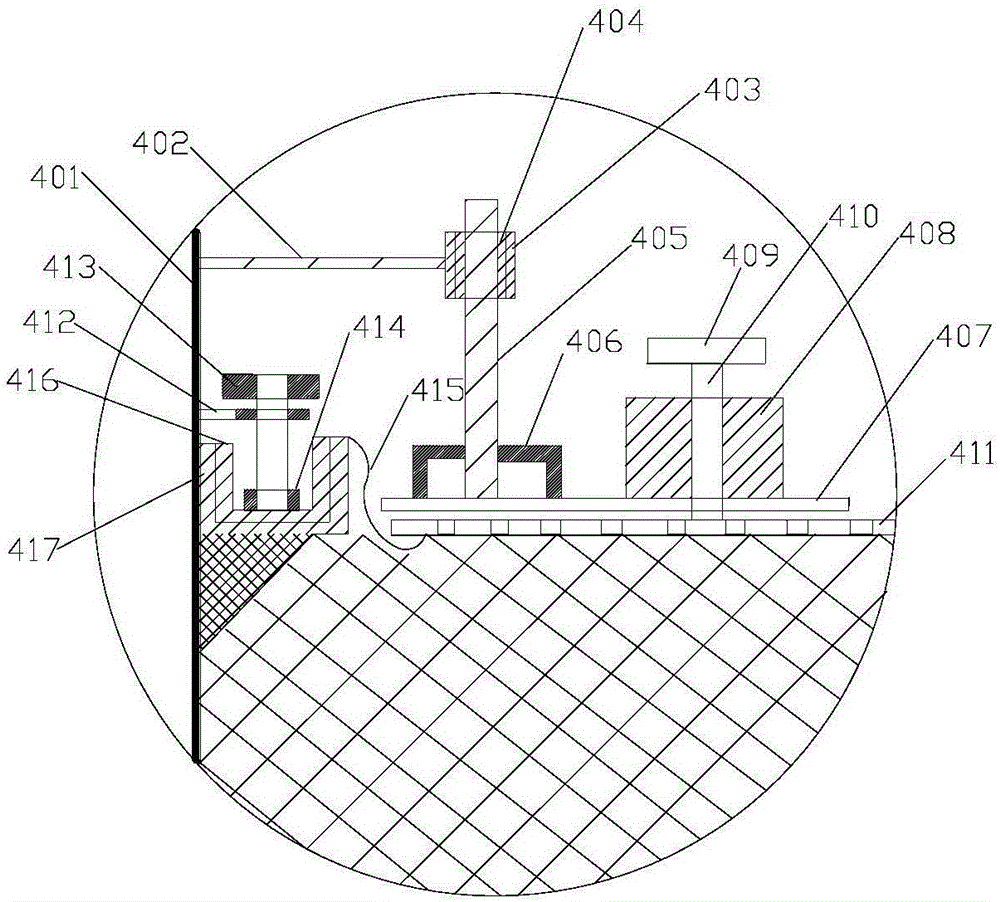

[0028] The method for separating and recovering the organic solvent in the tail gas of meal evaporation of the present invention adopts two semi-fixed adsorption towers equipped with highly microporous hydrophobic adsorption resins to alternately perform adsorption, and one of the adsorption towers performs adsorption while the other adsorption tower performs adsorption. Regeneration of adsorption resin; the condensed water of steam regeneration uses macroporous adsorption resin to further recover the organic solvent. The specific steps are:

[0029] a: Coarse filtration of exhaust gas: coarsely filter the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap