Composite hydrogen storage material containing calcium carbide and preparation method thereof

A hydrogen storage material, calcium carbide technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of complex preparation process of nano-catalysts, reduced hydrogen desorption activation energy, poor reversibility, etc., and achieve good reversible hydrogen absorption. performance, improvement of hydrogen storage performance, effect of low hydrogen desorption temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

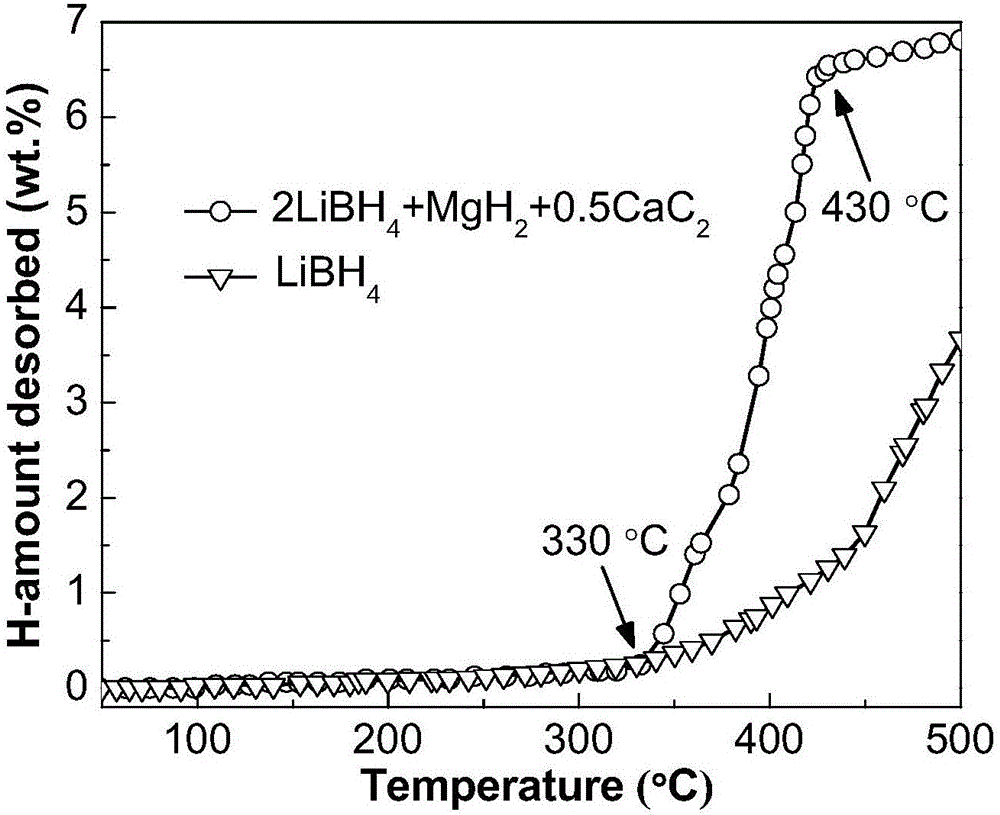

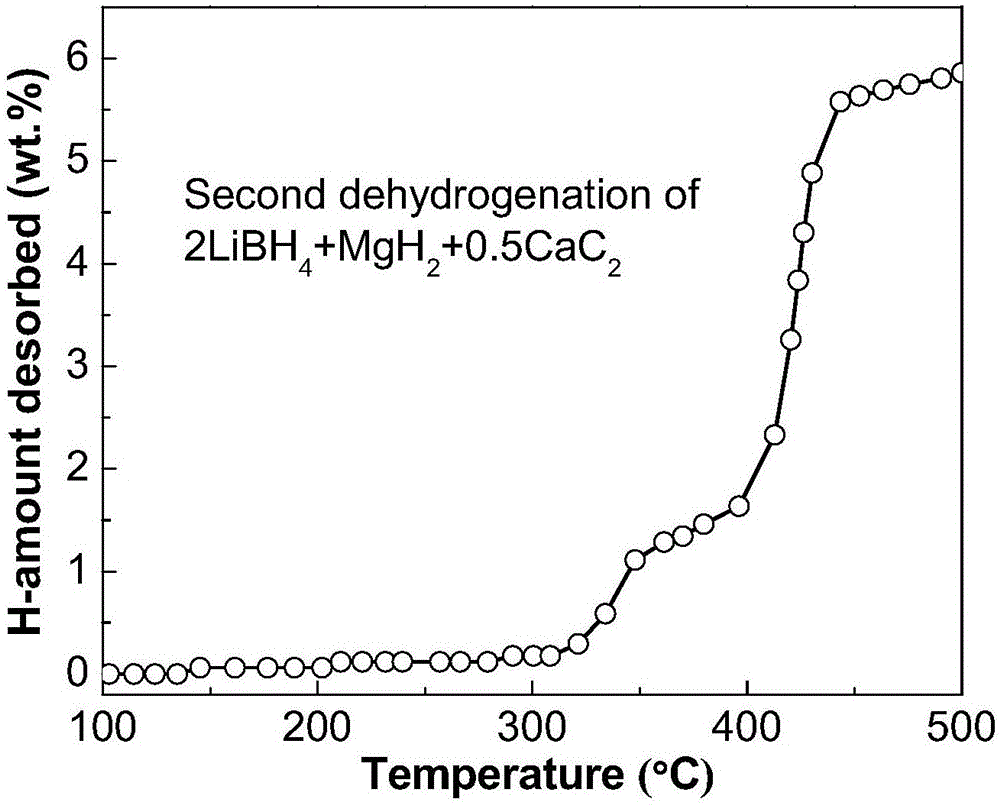

[0024] The commercially available irregular small block calcium carbide (CaC 2 , The purity is not less than 97%) mechanically crushed into powder with a particle size of less than 500μm; according to the 2:1:0.5 molar ratio, weigh lithium borohydride (LiBH 4 ), magnesium hydride (MgH 2 ) And calcium carbide powder and mixed; LiBH 4 , MgH 2 And CaC 2 Pour the mixed powder into a stainless steel ball mill tank with a volume of 250mL, and fill the ball mill tank with 1atm argon gas; use a planetary ball mill to ball mill the mixed powder for 10 hours (ball-to-material ratio 20:1, speed 400rpm), that is Available 2LiBH 4 +MgH 2 +0.5CaC 2 Composite hydrogen storage material. by figure 1 It can be seen that the obtained 2LiBH 4 +MgH 2 +0.5CaC 2 The composite hydrogen storage material starts to release hydrogen at 330°C and basically ends at 430°C, and the amount of hydrogen released reaches 6.8wt.%. In comparison, pure LiBH 4 The hydrogen desorption temperature is high and the hydrog...

Embodiment 2

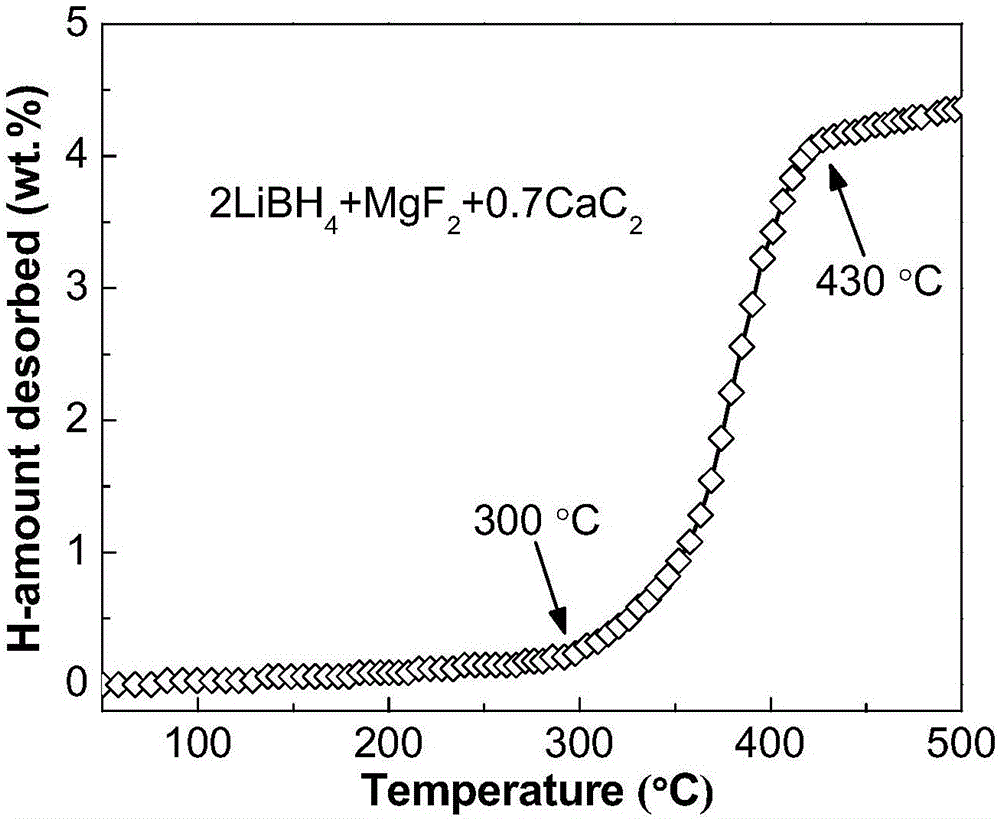

[0026] The commercially available irregular small block calcium carbide (CaC 2 , The purity is not less than 97%) mechanically crushed into powder with a particle size of less than 500μm; LiBH is respectively weighed according to the molar ratio of 2:1:0.7 4 , Magnesium fluoride (MgF 2 ) And CaC 2 Powder and mix; LiBH 4 , MgF 2 And CaC 2 Pour the mixed powder into a stainless steel ball mill tank with a volume of 250mL, and fill the ball mill tank with 1atm argon gas; use a planetary ball mill to ball mill the mixed powder for 10 hours (ball-to-material ratio 20:1, speed 400rpm), that is Available 2LiBH 4 +MgF 2 +0.7CaC 2 Composite hydrogen storage material. by image 3 It can be seen that the obtained 2LiBH 4 +MgF 2 +0.7CaC 2 The composite hydrogen storage material starts to release hydrogen at 300°C and basically ends at 430°C, and the amount of hydrogen released reaches 4.5wt.%.

Embodiment 3

[0028] The commercially available irregular small block calcium carbide (CaC 2 , The purity is not less than 97%) mechanically crushed into powder with a particle size of less than 500μm; LiBH is respectively weighed according to the 2:1:1 molar ratio 4 , MgH 2 And CaC 2 Powder and mix; LiBH 4 , MgH 2 And CaC 2 Pour the mixed powder into a stainless steel ball mill tank with a volume of 250mL, and fill the ball mill tank with 2atm nitrogen; use a planetary ball mill to mill the mixed powder for 8 hours (ball-to-material ratio 30:1, speed 400rpm). Obtain the 2LiBH 4 +MgH 2 +CaC 2 Composite hydrogen storage material. by Figure 4 It can be seen that the obtained 2LiBH 4 +MgH 2 +CaC 2 The composite hydrogen storage material starts to release hydrogen at 325°C and basically ends at 420°C, and the amount of hydrogen released reaches 4.7wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com