Composite nano zirconium oxide with uniform particle size distribution, and continuous preparation method and equipment thereof

A nano-zirconia, particle size distribution technology, applied in zirconia, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of long preparation process, not solid solution, etc. The effect of good performance and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

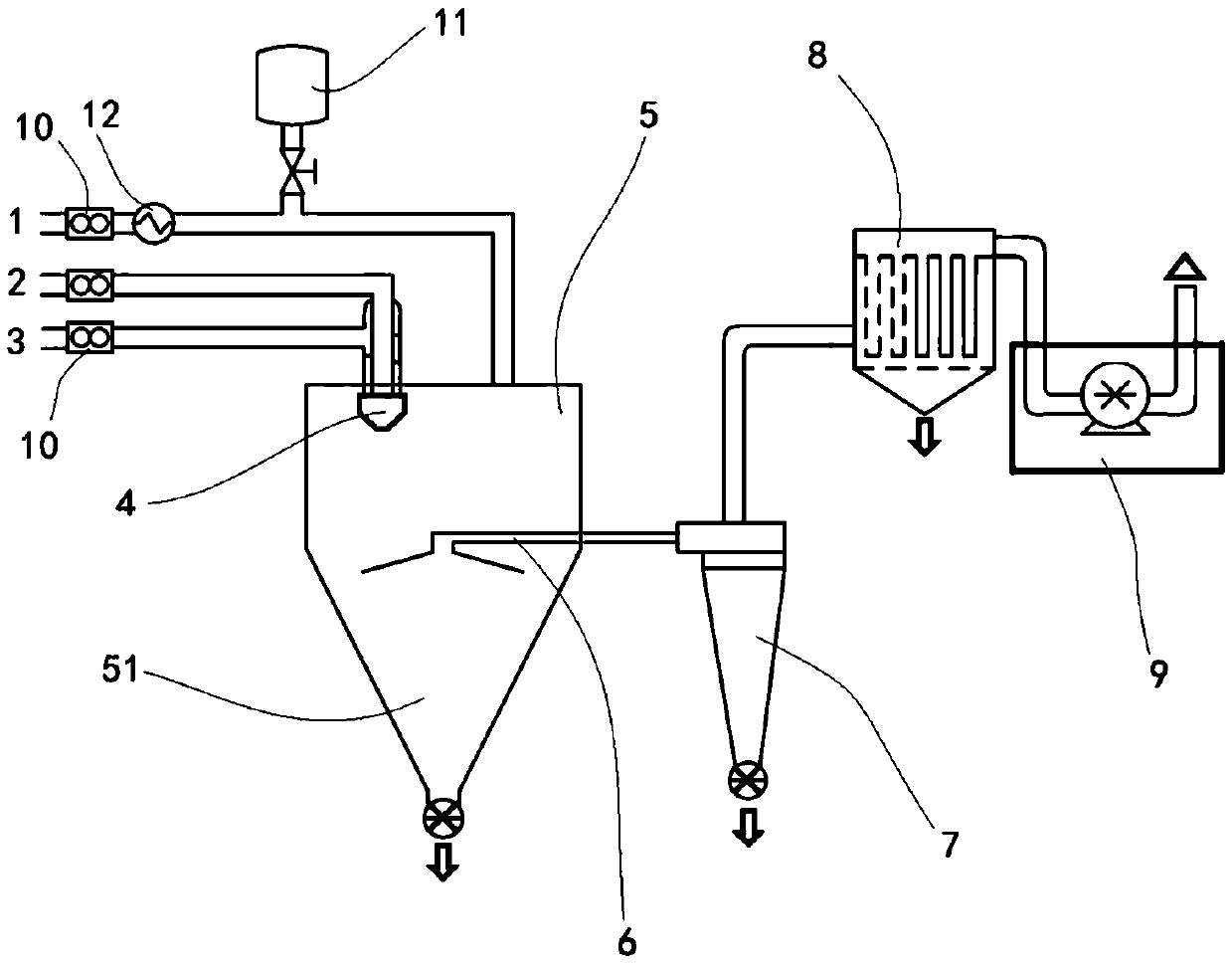

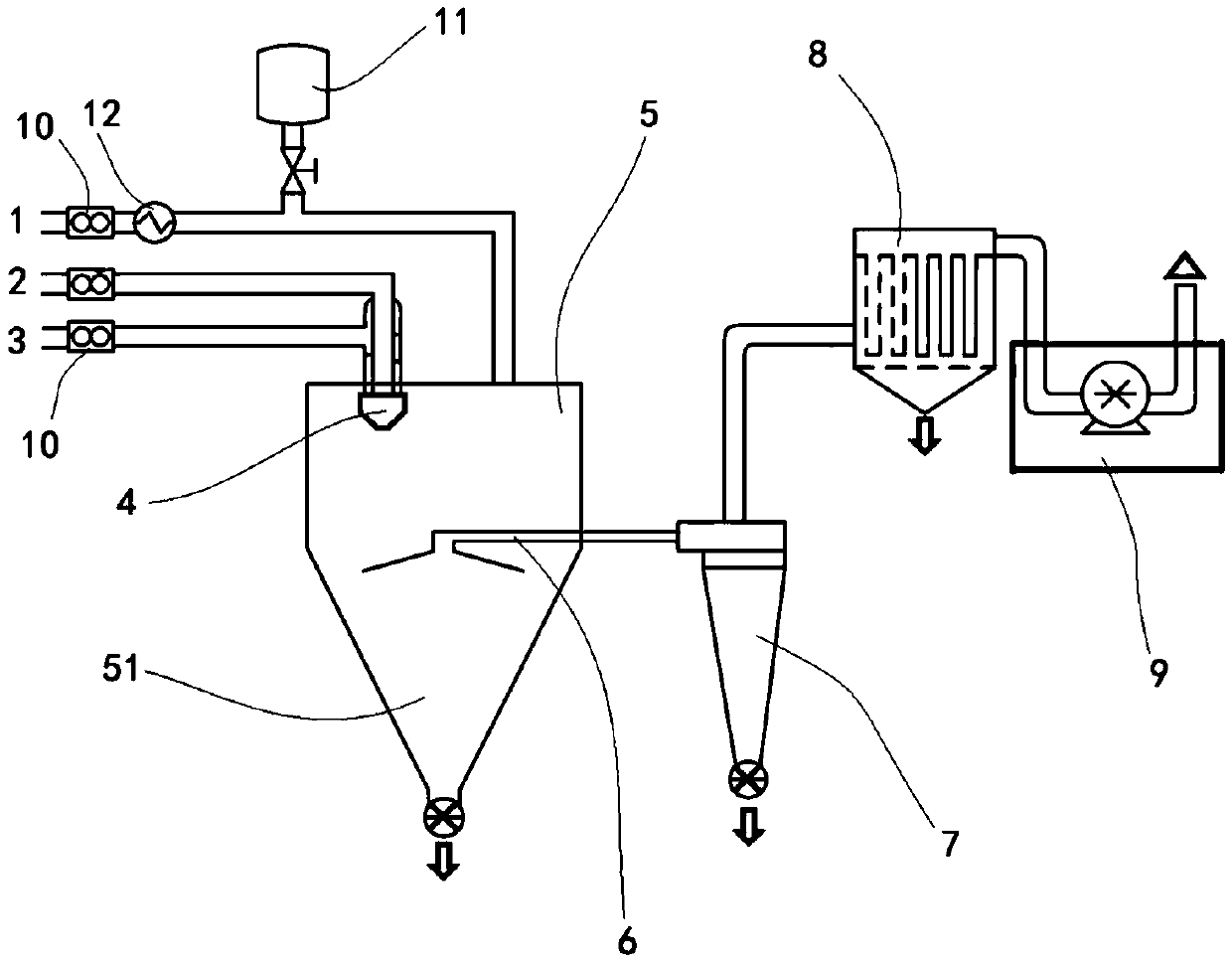

[0068] A device for continuous preparation of composite nano zirconia, which includes a feed system, a reaction system and a product collection system, wherein the feed system includes two inlets, respectively the precursor of volatile zirconia and the stable The inlet of the precursor mixture of the agent and the inlet of the water vapor; the reaction system is used for the hydrolysis reaction between the water vapor and the precursor of the volatile zirconia and the precursor of the stabilizer, including a reactor, preferably, the reactor A heating device is provided outside to control the temperature of the reactor, and the product collection system is used to complete the collection of the generated nano-zirconia product. Wherein, feed system can have two kinds of implementation schemes at least, the first kind of scheme is:

[0069] Such as figure 1 As shown: the feed system includes three gas feeds, the first gas route is connected with the first gas inlet pipe 1, the f...

Embodiment 2

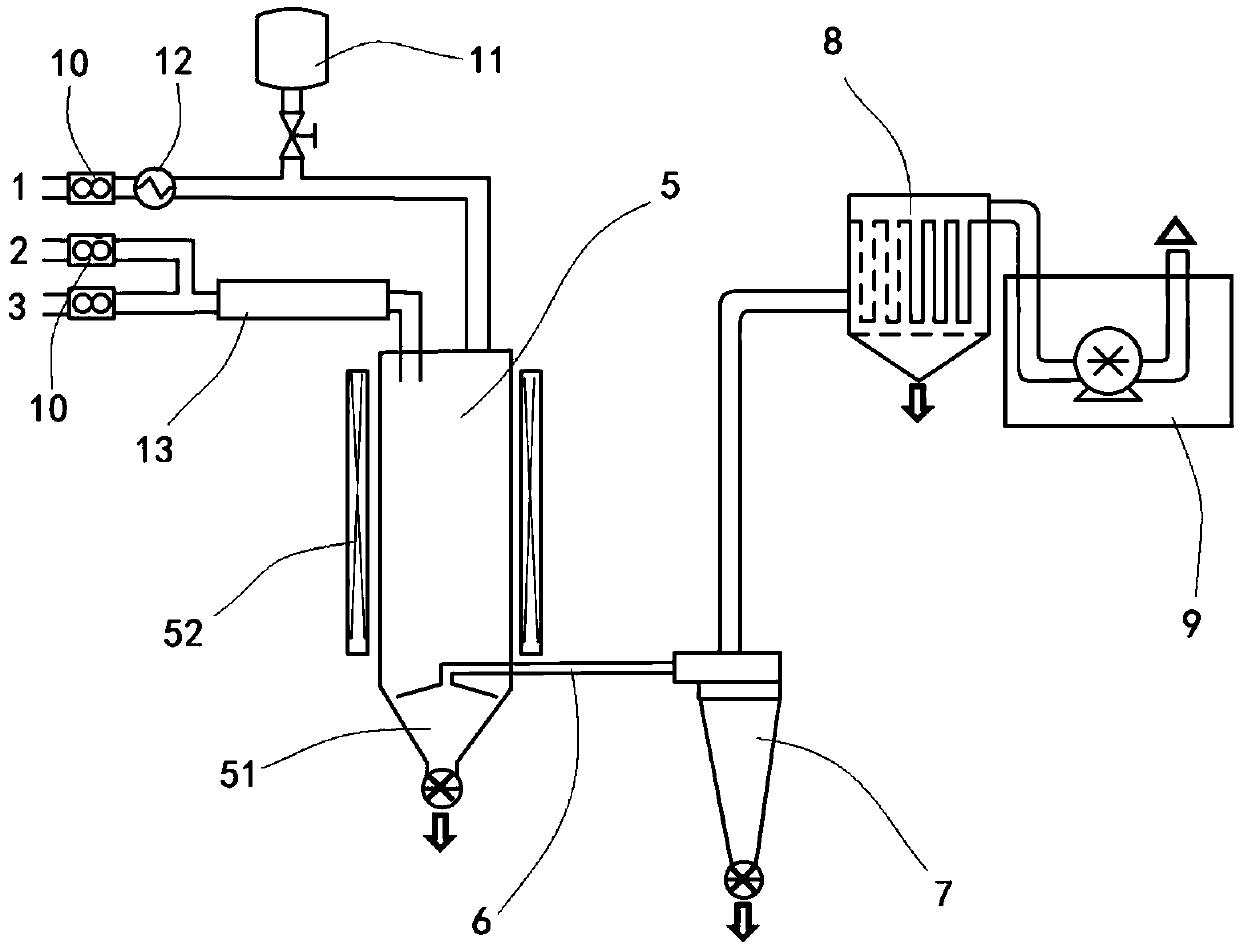

[0077] A kind of equipment for the continuous preparation of composite nano zirconia, the feeding system of this embodiment is the second scheme not listed in embodiment 1, specifically: as figure 2 As shown: the feeding system is composed of two gas feeds. The first gas route is connected to the first gas inlet pipe 1, the first heater 12 and the mixer 11 in sequence. The carrier gas is fed from the first gas inlet pipe 1. The flow meter 10 is used to precisely control the flow rate. After the precursors of zirconia and stabilizer are uniformly mixed in the mixer 11, they enter the pipeline and are carried by the carrier gas heated by the first heater 12 into the reactor 5. At the top, the structure of this gas path is basically the same as that in the first scheme; the second gas path is provided with a second inlet pipe and a third inlet pipe, and the carrier gas and water pass through the second inlet pipe 2 and the third inlet pipe respectively. After the intake pipes 3 ...

Embodiment 3

[0082] use figure 1 The nano-zirconia continuous production equipment, the first gas path uses high-purity nitrogen to carry the gas of zirconium tetrachloride and yttrium isopropoxide, of which the vapor pressures of zirconium tetrachloride and yttrium isopropoxide are 30kPa and 1kPa respectively, and the flow rate 1.5m 3 / h. The air flow in the second air path is 2.5m 3 / h, gas path 3 uses n-pentane, and its flow rate is 1.0m 3 / h. The second gas path and the third gas path enter the reactor through the casing, and an igniter is installed near the outlet of the mixer. After entering the reactor, n-hexane burns. The temperature in the reactor is 720°C, and the generated mixed The heterozygous zirconium hydroxide can be rapidly decomposed at high temperature to generate stable zirconium oxide.

[0083] The reaction product is a white powder, which is analyzed by laser dynamic light scattering, and the average particle size of zirconia doped with yttrium oxide is 4nm. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com