Novel energy-saving and environment-friendly waterproof plastering gypsum and preparation method thereof

A technology for plastering gypsum, energy saving and environmental protection, which is applied in the fields of industrial waste utilization and building materials, can solve problems such as inability to use, waste, and powder drop, and achieve the effects of low shrinkage, strong viscosity and excellent waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

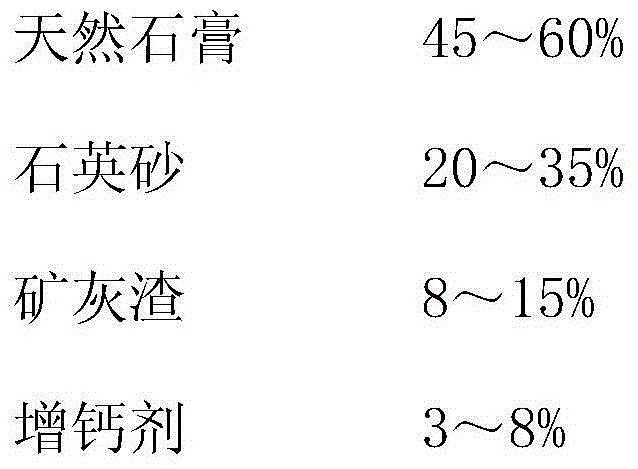

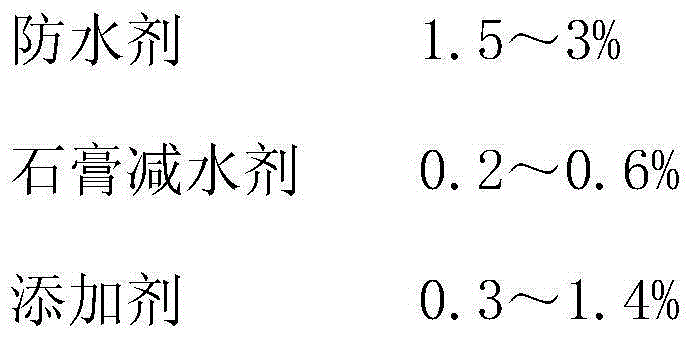

[0027] A new type of energy-saving and environmentally-friendly waterproof plaster and its preparation method. Taking 100kg of dry powder of new-type energy-saving and environmentally-friendly waterproof plaster as an example, the content of each component is as follows:

[0028]

[0029] Natural gypsum is made of natural gypsum stone through calcination, grinding, whitening, roasting and other technological processes, and the screening fineness is 160 mesh;

[0030] Quartz sand is natural quartz stone that has been crushed, finely ground, and screened with a fineness of 60 mesh;

[0031] The ash slag is the waste slag of the power plant boiler. After desulfurization, it is magnetically separated by a magnetic separator, and then processed by fine grinding. The screening fineness is 60 mesh;

[0032] Calcium increasing agent, the main components of calcium hydroxide and calcium oxide, the proportion of calcium hydroxide and calcium oxide is 1:0.2;

[0033] The waterproofing agent is mad...

Embodiment 2

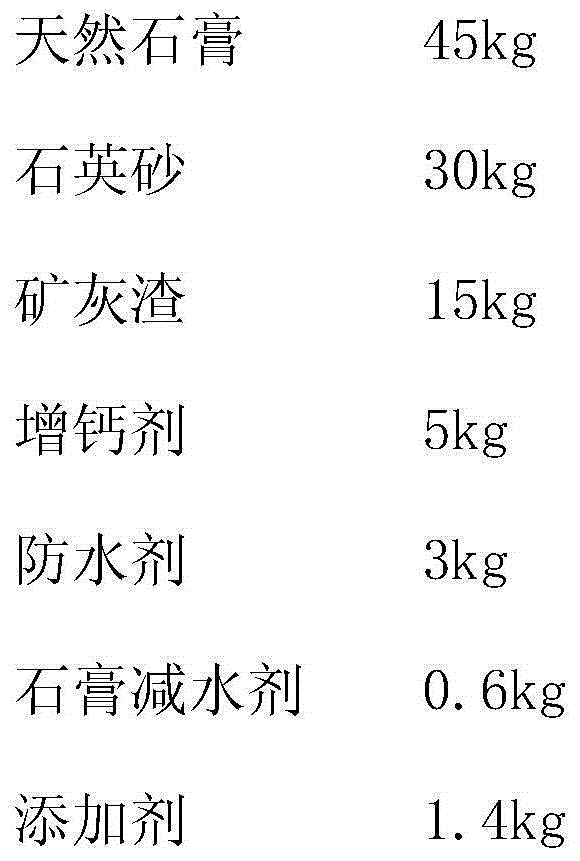

[0038] A new type of energy-saving and environmentally-friendly waterproof plaster and its preparation method. Taking 100kg of dry powder of new-type energy-saving and environmentally-friendly waterproof plaster as an example, the content of each component is as follows:

[0039]

[0040] Among them: natural gypsum is made of natural gypsum stone through calcination, grinding, whitening, roasting and other technological processes, and the screening fineness is 170 mesh;

[0041] Quartz sand is natural quartz stone that has been crushed, finely ground, and screened with a fineness of 70 mesh;

[0042] The ash slag is the waste slag of the power plant boiler. After desulfurization, it is magnetically separated by a magnetic separator, and then processed by fine grinding. The screening fineness is 65 mesh;

[0043] The main components of calcium enhancer are calcium hydroxide and calcium oxide, and the proportion of calcium hydroxide and calcium oxide is 1:0.3;

[0044] The waterproofing a...

Embodiment 3

[0050] A new type of energy-saving and environmentally-friendly waterproof plaster and its preparation method. Taking 100kg of dry powder of new-type energy-saving and environmentally-friendly waterproof plaster as an example, the content of each component is as follows:

[0051]

[0052] Among them: natural gypsum is made of natural gypsum stone through calcination, grinding, whitening, roasting and other technological processes, and the screening fineness is 180 mesh;

[0053] Quartz sand is natural quartz stone that has been crushed, finely ground, and screened with a fineness of 80 mesh;

[0054] The ash slag is the waste slag of the power plant boiler. After desulfurization, it is magnetically separated by a magnetic separator, and then processed by fine grinding. The screening fineness is 70 mesh;

[0055] Calcium increasing agent, the main components of calcium hydroxide and calcium oxide, the proportion of calcium hydroxide and calcium oxide is 1:0.4;

[0056] The waterproofing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com