Preparation method of ornithine aspartate

A technology of ornithine aspartate and ornithine aspartate is applied in the field of preparation of ornithine aspartate, which can solve the problems of inconvenient procurement, transportation and use of ammonia water, unfavorable health of workers in the production environment, and the like. Low cost, easy industrial production, high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

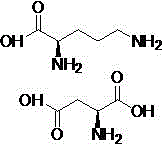

[0035] The present invention relates to the preparation method of aspartic acid ornithine, the structural formula of described aspartic acid ornithine is:

[0036]

[0037] The preparation method comprises the following steps:

[0038] Step 1: Using L-ornithine acetate and L-aspartic acid as starting materials, adding acid-binding agent ammonium carbonate to neutralize the acetate group of L-ornithine acetate to obtain free L-ornithine acetate Amino acid; L-ornithine and L-aspartic acid react to form a salt of the two, namely aspartic acid ornithine;

[0039] Step 2: then using the difference in solubility of ornithine aspartate and ammonium acetate in the crystallization solvent to remove ammonium acetate to obtain pure ornithine aspartate with a yield of more than 90%.

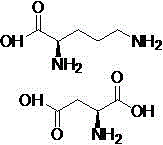

[0040] The synthetic route of described preparation method is:

[0041] .

[0042] Step one is specifically:

[0043] Dissolve L-ornithine acetate and L-aspartic acid in water to form a suspension, ...

Embodiment 1

[0058] Add 22.5g of L-ornithine acetate (monohydrate), 13.3g of L-aspartic acid, and 20mL of purified water, and stir. Ammonium carbonate solution (9.9 g of ammonium carbonate dissolved in 40 mL of purified water) was added dropwise to the above suspension, with CO 2 Gas evolution with slight exotherm (control of drop rate). The suspension gradually became clear. After the addition, the stirring was continued for 10 minutes, and the pH value of the reaction solution was about 7.0-8.0. The temperature was raised to 70-80°C, and 150 mL of methanol was slowly added dropwise, and a solid precipitated out. After heat preservation and crystallization for 2h, it was slowly lowered to room temperature, and stirring was continued for 2h. Filter, and rinse the solid with about 50mL of methanol:water=4:1 mixture once, and then rinse with methanol (50mL×2). After pumping to dryness, 21.7 g of wet solid was obtained. It can be directly used for refining without drying.

[0059]Add 21...

Embodiment 2

[0061] Add 21.0g of L-ornithine acetate, 13.3g of aspartic acid, and 20mL of purified water, and stir. Ammonium carbonate solution (9.6 g ammonium carbonate dissolved in 40 mL purified water) was added dropwise to the above suspension, with CO 2 Gas evolution with slight exotherm (control of drop rate). The suspension gradually became clear. After the addition, the stirring was continued for 10 minutes, and the pH value of the reaction solution was about 7.0-8.0. The temperature was raised to 70-80°C, and 150 mL of ethanol was slowly added dropwise, and a solid precipitated out. After heat preservation and crystallization for 2h, it was slowly lowered to room temperature, and stirring was continued for 2h. Filter, and rinse the solid with about 50mL of ethanol: water = 4:1 mixture once, and then rinse with ethanol (50mL×2). After pumping to dryness, 22.5 g of wet solid was obtained. It can be directly used for refining without drying.

[0062] Add 22.5g of wet crude orni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com