High-performance self-adhesion asphalt polymeric membrane composite rolled waterproof material and preparation method thereof

A polymer film and waterproof membrane technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, asphalt material adhesives, etc., can solve the problems of easy separation of polymer reinforced membranes and achieve shrinkage Strong adaptability to deformation and cracking, good weather resistance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

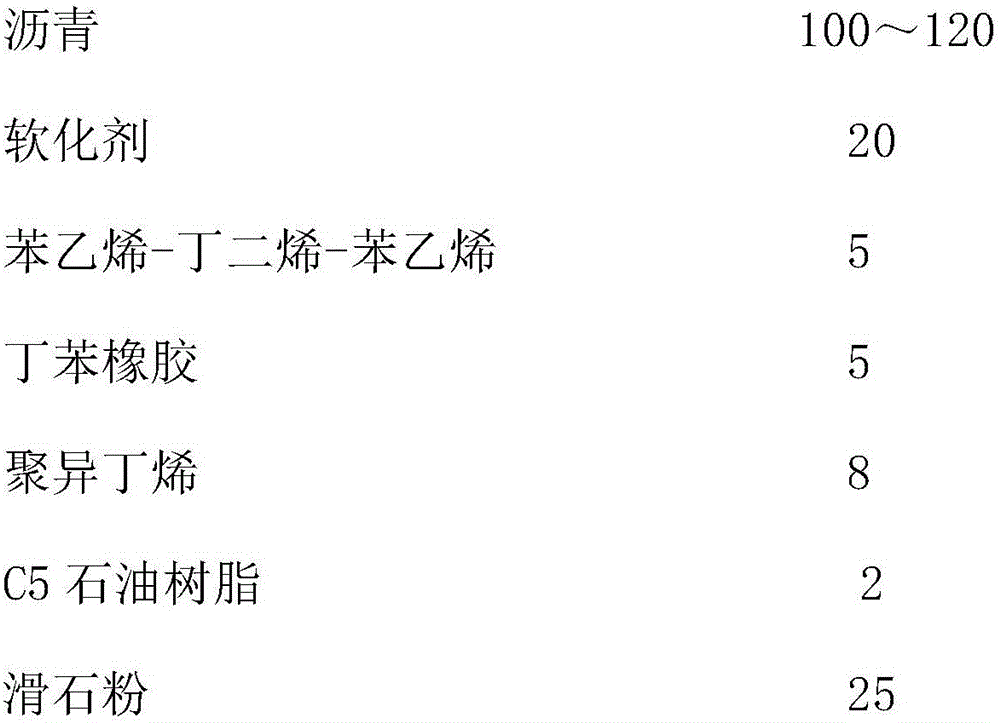

[0021] 1. Calculated by mass parts, the chemical composition of high-performance self-adhesive asphalt material is as follows:

[0022]

[0023] 2. Preparation of high-performance self-adhesive asphalt polymer membrane composite waterproof membrane

[0024] (1) Weigh 100-120 parts of asphalt, 5 parts of styrene-butadiene-styrene, 5 parts of styrene-butadiene rubber, 8 parts of polyisobutylene, 2 parts of C5 petroleum resin, 25 parts of stone powder slip, at a temperature of 130 ° C , add asphalt, softener, styrene-butadiene-styrene, styrene-butadiene rubber, polyisobutylene, talcum powder in sequence, and mix to obtain self-adhesive asphalt.

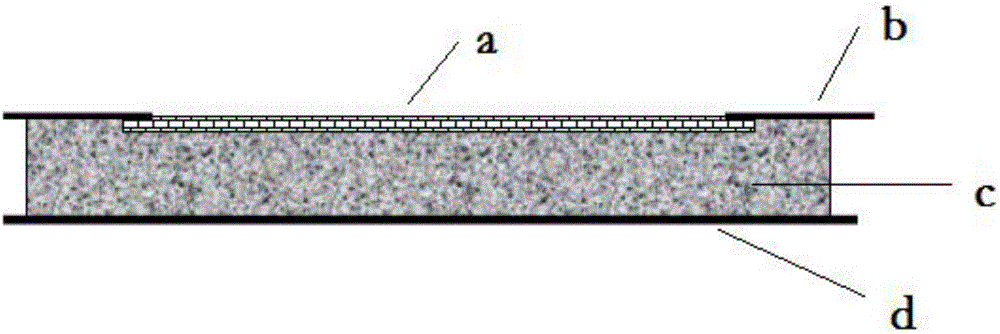

[0025] (2) After the coil forming process, the PET reinforced film is placed on the upper surface, the lower surface is coated with the self-adhesive asphalt prepared in the above steps, and the lower layer of the coil is covered with a PET isolation film, after thickness setting, cooling and shaping, and winding. Among them, the upp...

Embodiment 2

[0030] 1. Calculated by mass parts, the chemical composition of high-performance self-adhesive asphalt material is as follows:

[0031]

[0032] 2. Preparation of high-performance self-adhesive asphalt polymer membrane composite waterproof membrane

[0033] (1) Weigh 100-120 parts of asphalt, 20 parts of softener, 5 parts of styrene-butadiene-styrene, 5 parts of styrene-butadiene rubber, 8 parts of polyisobutylene, 8 parts of polyisobutylene, 25 parts of stone powder slip, in When the temperature is 130°C, add asphalt, polymer modifier, styrene-butadiene rubber, polyisobutylene, and talc in sequence, and mix to obtain self-adhesive asphalt.

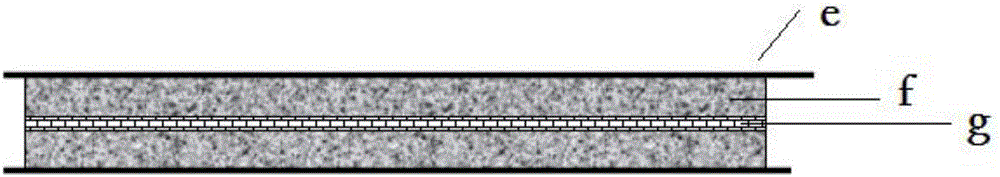

[0034] (2) After the coil forming process, the PET reinforced film is placed in the middle, and the self-adhesive asphalt prepared in the above steps is coated on both sides, and the upper and lower layers of the coil are covered with PET isolation film. After thickness setting, cooling and shaping, winding. Among them, the upper laye...

Embodiment 3

[0038] 1. Calculated by mass parts, the chemical composition of high-performance self-adhesive asphalt material is as follows:

[0039]

[0040] 2. Preparation of high-performance self-adhesive asphalt polymer membrane composite waterproof membrane

[0041] (1) Weigh 140-150 parts of asphalt, 15 parts of softener, 10 parts of styrene-butadiene-styrene, 6 parts of styrene-butadiene rubber, 3 parts of polyisobutylene, 8 parts of C5 petroleum resin, 30 parts of stone powder slip, At a temperature of 130°C, add asphalt, styrene-butadiene-styrene, styrene-butadiene rubber, polyisobutylene, and talcum powder in sequence, and mix to obtain self-adhesive asphalt.

[0042] (2) After the coil forming process, the HDPE reinforced film is placed on the upper surface, the lower surface is coated with the high-performance self-adhesive asphalt prepared in the above steps, and the lower layer of the coil is covered with a PET isolation film, after thickness setting, cooling and setting, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com