A kind of processing method of high temperature coal tar

A technology of high-temperature coal tar and process method, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of large amount of metal deposition, large metal content, fast deactivation speed, etc., and achieve reduction of processing capacity, The effect of large aperture and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

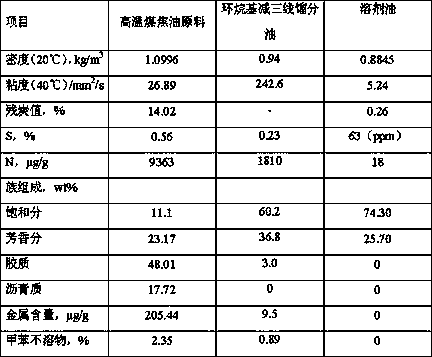

[0041] The test raw materials are the high-temperature coal tar and the third-line distillate described in Table 1, and the alcohol is ethanol. The reaction conditions are shown in Table 2, and the reaction results are shown in Table 3.

Embodiment 2

[0043] The test raw materials are high-temperature coal tar and the third-line distillate oil described in Table 1. The alcohols are ethanol, and 1-butyl-3-methylimidazole tetrafluoroborate is added simultaneously. The amount of ethanol is the same as that of high-temperature coal tar. The weight ratio is 1:25000, the reaction conditions are shown in Table 2, and the reaction results are shown in Table 3.

Embodiment 3

[0045] The test raw materials are the high-temperature coal tar and the third-line distillate oil described in Table 1, the alcohols are methanol, and additives 1-butyl-3-methylimidazole hexafluoroborate and demulsifier are added at the same time. The weight ratio of the amount to the high-temperature coal tar is 1:25000, and the amount of the demulsifier is 1 / 20000 of the weight of the coal tar. The reaction conditions are shown in Table 2, and the reaction results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com