Ni-S-W-C hydrogen evolution electrode and preparation method thereof

A hydrogen evolution electrode and anode technology, applied in the field of electrocatalytic hydrogen evolution, can solve the problems of limited storage capacity, difficulty in large-scale industrial application, high energy consumption, etc., and achieve high hydrogen evolution catalytic activity, excellent stability, and low hydrogen evolution overpotential effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a method for preparing the Ni-S-W-C hydrogen evolution electrode described in the above technical solution, comprising the following steps:

[0029] (1) An electroplating aqueous solution is provided, and the electroplating aqueous solution includes components of the following concentrations: nickel source 80-160g / L, thiourea 80-130g / L, tungsten source 10-45g / L, lysine 1-5g / L , Complexing agent 60~100g / L, H 3 BO 3 20-60g / L, conductive agent 20-60g / L, saccharin 0.5-5.0g / L, sulfosalicylic acid 5-30g / L;

[0030] (2) Using the nickel substrate as the cathode and the anode, the distance between the cathode and the anode being 0.5 to 3.0 cm, performing electroplating with the electroplating aqueous solution obtained in the step (1) to obtain a Ni-S-W-C hydrogen evolution electrode.

[0031] The invention provides an electroplating aqueous solution. The electroplating aqueous solution includes components with the following concentrations:...

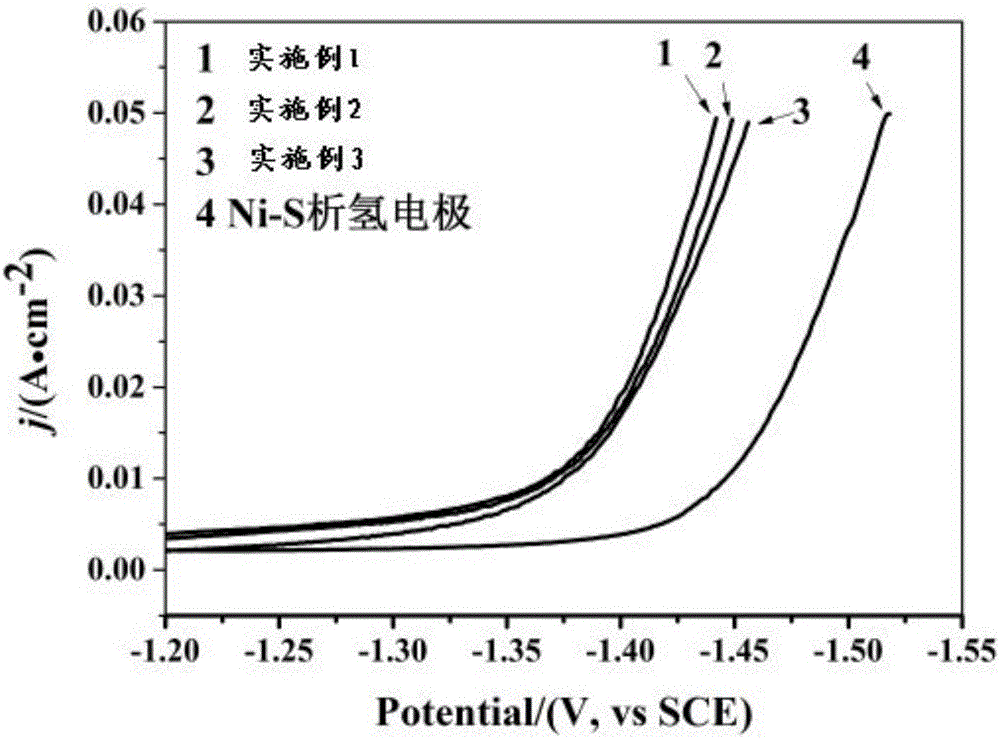

Embodiment 1

[0053] (1) Pretreatment of Ni matrix

[0054] First, the Ni sheet is mechanically polished to remove the oxide on the surface to make it metallic luster, and then cleaned with deionized water; then ultrasonically oscillated in lye and absolute ethanol for 20 minutes for chemical degreasing, wherein the lye is 15g / LNaOH, 60g / L Na 3 PO 4 12H 2 O, 25g / L Na 2 CO 3 and 15g / LNa 2 SiO 3 Then rinse it with deionized water, boil and etch it in 20% hydrochloric acid for 5 minutes, then rinse it with deionized water, dry it naturally, and immerse it in absolute ethanol solution for later use;

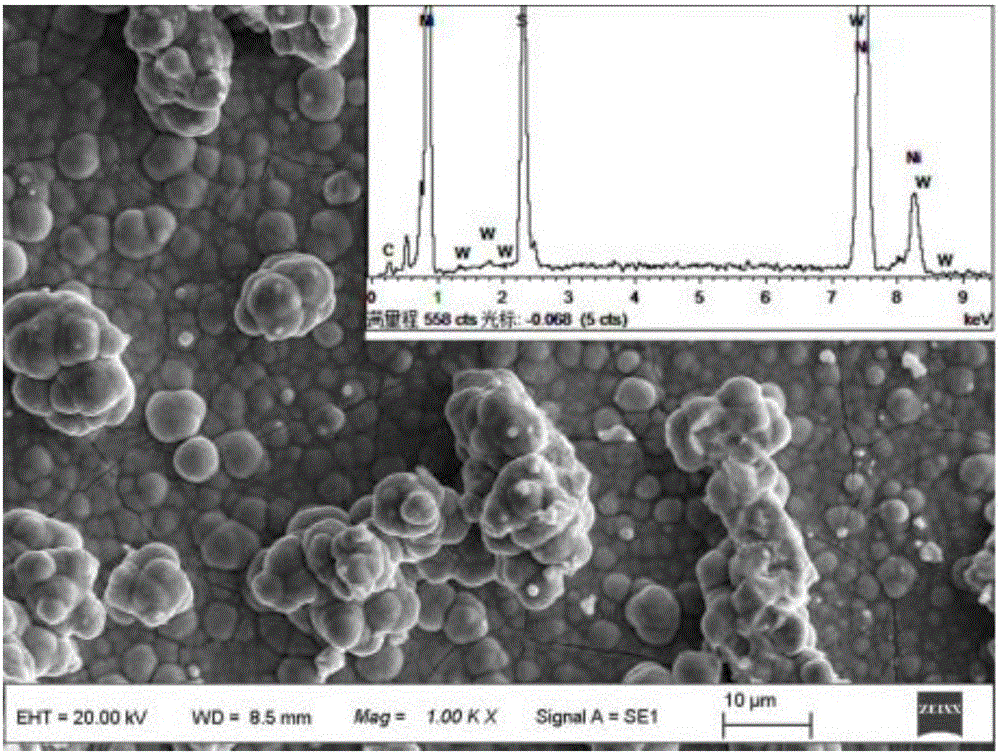

[0055] (2) Preparation of Ni-S-W-C hydrogen evolution electrode by pulse electrodeposition

[0056] A double-anode and single-cathode system is adopted, and the Ni substrate treated in step (1) is used as the cathode and the anode. Composition of Ni-S-W-C plating solution: 140g / L NiSO 4 ·6H 2 O, 100g / L thiourea, 15g / L Na 2 WO 4 2H 2 O, 1g / L Lysine, 70g / LNa 3 C 6 h 5 o 7 2H 2 O, ...

Embodiment 2

[0060] Step (1) is the same as step (1) in Example 1;

[0061] (2) Preparation of Ni-S-W-C hydrogen evolution electrode by pulse electrodeposition

[0062] A dual-anode and single-cathode system is adopted, and the nickel sheet treated in step (1) is used as the cathode and the anode. Composition of Ni-S-W-C plating solution: 120g / L NiSO 4 ·6H 2 O, 80g / L thiourea, 10g / L Na 2 WO 4 2H 2 O, 3g / L Lysine, 80g / L Na 3 C 6 h 5 o 7 2H 2 O, 40g / L H 3 BO 3 , 20g / L NaCl, 1.5g / L saccharin, 5g / L sulfosalicylic acid, the pH value of the plating solution is 3, the temperature of the plating solution is 50°C; the pulse peak current density is 1A / dm 2 , the duty cycle is 0.85, the pulse frequency is 100Hz, and the electrodeposition time is 70min. Rinse with deionized water after electroplating to remove residual plating solution, and dry naturally to prepare Ni-S-W-C hydrogen evolution electrode.

[0063] Step (3) is the same as step (3) in Example 1, and the hydrogen evolution li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com