Preparation method of inorganic-organic composite inkjet printing paste

A technology of inkjet printing and preparation method, applied in dyeing method, textile and papermaking, etc., can solve the problems of poor fluidity of bentonite mineral paste, low definition of printing pattern, reduced fabric permeability, etc., and achieves improved fluidity, High color yield and fineness, reduction of organic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the preparation method of inorganic-organic composite inkjet printing paste, carry out following steps successively:

[0025] 1) Preparation of modified bentonite raw paste: 3 parts of sodium bentonite raw material, 1 part of methylamine, 0.5 part of triethylene glycol, and water, 100 parts in total; after mixing, stir at high speed and heat to above 80 °C for 1 h, and precipitate after standing Precipitate, wash with water, dry in vacuum, grind to make modified bentonite raw paste suitable for inkjet printing.

[0026] 2) Preparation of inkjet printing paste: 12 parts of modified bentonite raw paste, 1 part of sodium alginate raw paste, 8 parts of urea, 4 parts of sodium bicarbonate, 2 parts of sodium sulfate, 1 part of resist salt S, add water , a total of 100 parts, fully stirred evenly after mixing, and an environment-friendly inorganic-organic composite inkjet printing paste was obtained.

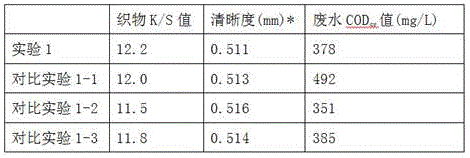

[0027] Experiment 1, using the printing paste obtained in th...

Embodiment 2

[0041] The preparation method of inorganic-organic composite inkjet printing paste, carries out the following steps successively:

[0042] 1) Preparation of modified bentonite raw paste: 10 parts of calcium-based bentonite raw materials, 3 parts of n-propylamine, 1.5 parts of glycerol, and water, a total of 100 parts; after mixing, stir at high speed and heat to above 80 ℃ for 1 h, and precipitate after standing Precipitate, wash with water, dry in vacuum, grind to make modified bentonite raw paste suitable for inkjet printing.

[0043] 2) Preparation of inkjet printing paste: 1 part of modified bentonite raw paste, 10 parts of carboxymethyl cellulose raw paste, 2 parts of urea, 4 parts of sodium bicarbonate, 2 parts of sodium sulfate, 1 part of anti-staining salt S , add water, a total of 100 parts, mix well and stir evenly to prepare an environment-friendly inorganic-organic composite inkjet printing paste.

[0044] Experiment 2: Using the printing paste obtained in Example...

Embodiment 3

[0052] The preparation method of inorganic-organic composite inkjet printing paste, carries out the following steps successively:

[0053] 1) Preparation of modified bentonite raw paste: 6 parts of sodium-based bentonite raw materials, 2 parts of n-butylamine, 1 part of triethylene glycol, and water, 100 parts in total; after mixing, stir at high speed and heat to above 80 °C for 1 h, after standing The precipitate was precipitated, washed with water, dried in vacuum, and ground to make a modified bentonite paste suitable for inkjet printing.

[0054] 2) Preparation of inkjet printing paste: 6 parts of modified bentonite raw paste, 6 parts of processed starch raw paste, 4 parts of urea, 4 parts of sodium bicarbonate, 2 parts of sodium sulfate, 1 part of anti-staining salt S, add water, A total of 100 parts are mixed and fully stirred evenly to obtain an environment-friendly inorganic-organic composite inkjet printing paste.

[0055] Experiment 3: Using the printing paste obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com