Analysis method of gold in gold saltcyanide

An analysis method, cyanide technology, applied in the field of analysis, can solve problems such as cyanide pollution, achieve the effect of eliminating cyanide pollution and overcoming impurity interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Weigh 100g of anhydrous sodium carbonate, 25g of anhydrous borax, 50g of silicon dioxide, 300g of lead oxide, and mix evenly; weigh 0.1g of potassium aurous cyanide, 2.0g of flour and 60g of flux, and put them in a container and mix evenly, and cover it with a layer of sodium chloride; put the container in a high-temperature furnace and smelt at 1100°C for 30 minutes; the smelted lead alloy is separated by ash blowing at 900°C, and the end point is to blow off the lead ash; The obtained gold particles are heated, washed and dried with 5% dilute nitric acid solution; the weight of gold is weighed and the gold result is calculated. This parallel test was performed 7 times, and the measurement results are shown in Table 1 below.

Embodiment 2

[0020] Embodiment 2: Take by weighing 200g anhydrous sodium carbonate, 50g anhydrous borax, 100g silicon dioxide, 600g lead oxide, mix uniformly; Take by weighing 1.0g potassium gold cyanide, 3.0g flour and 150g flux, pack in the container and Mix evenly and cover with a layer of sodium chloride; put the container in a high-temperature furnace and smelt at 1300°C for 50 minutes; the smelted alloy is separated by ash blowing at 1000°C, and the lead ash is blown clean to be the end point; The gold particles are heated, washed and dried with 5% dilute nitric acid solution; the weight of the gold particles is weighed and the gold result is calculated. This parallel test was performed 7 times, and the measurement results are shown in Table 1 below.

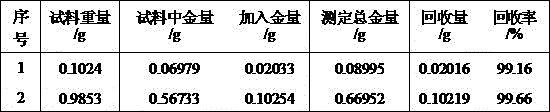

[0021] Table 1 embodiment measurement result

[0022] Example The measurement results / % average value / % The relative standard deviation / % 1 68.15,68.10,68.20,68.18,68.07,68.23,68.09 68.15 0.09 2 57.55,57.68,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com