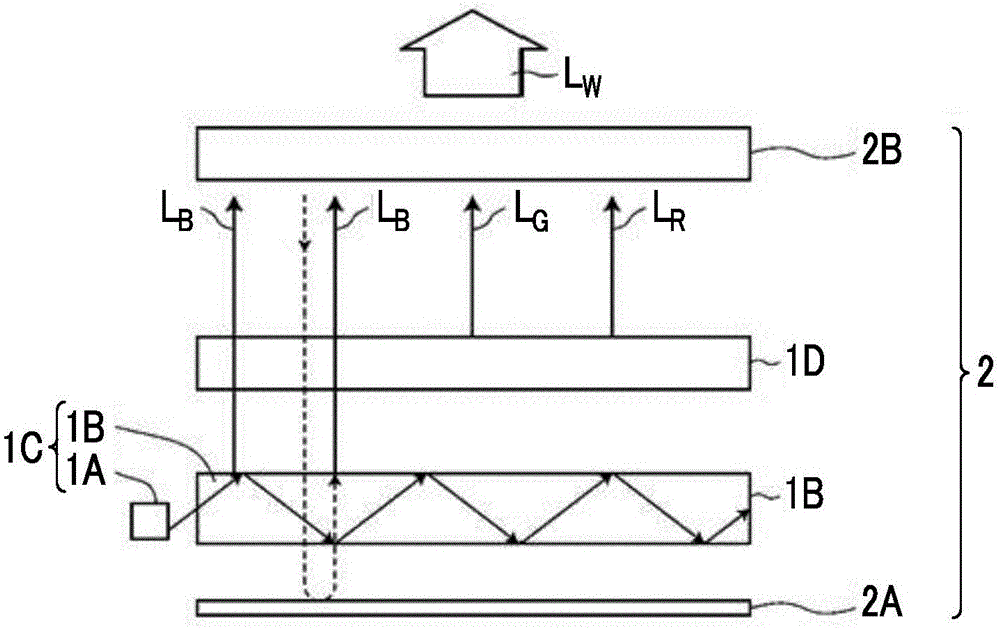

Wavelength conversion member, backlight unit provided with same, and liquid crystal display device

A wavelength conversion and wavelength conversion layer technology, applied in the field of backlight units, can solve problems such as the reduction of luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

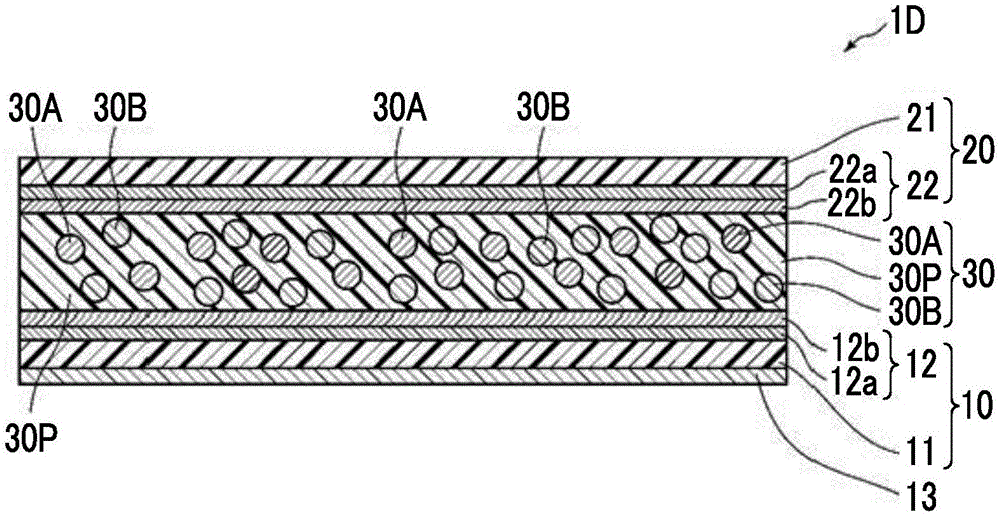

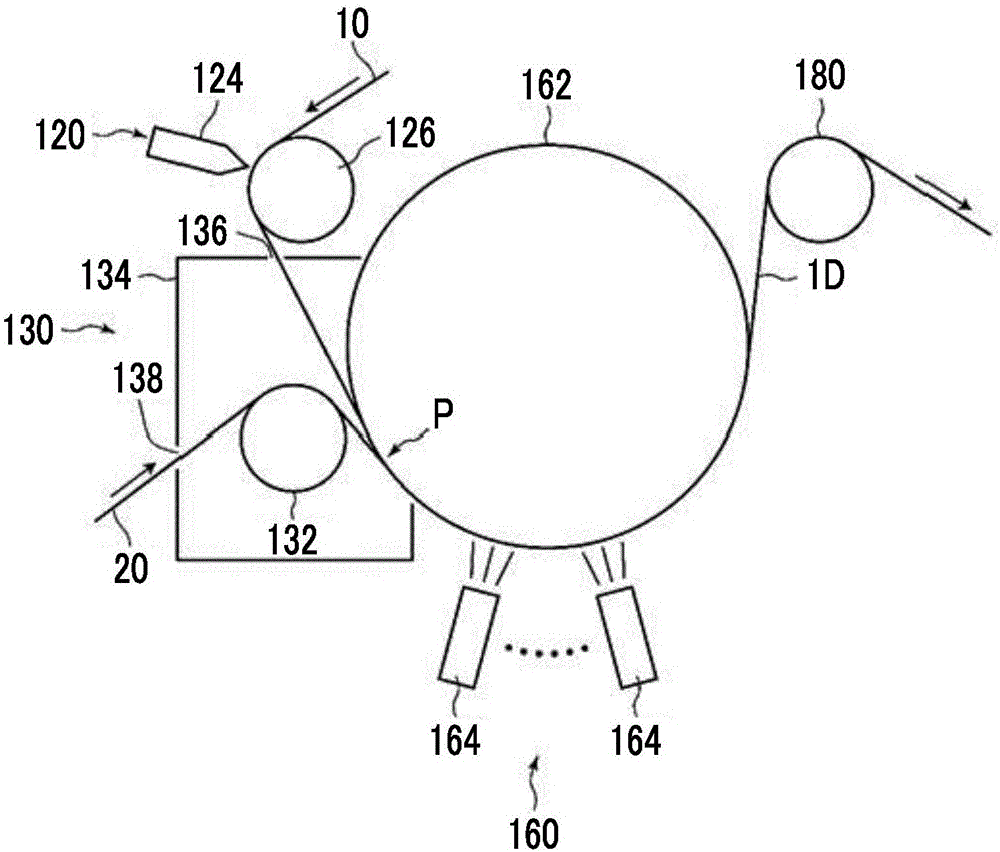

[0188] The first PET 1 was prepared, and was continuously transported at 1 m / min and 60 N / m tension, and the polymerizable composition 1 containing quantum dots was coated on the inorganic layer with a die coater to form a coating film with a thickness of 50 μm. Next, the first PET1 with the coating film formed thereon is wound around a support roll, the second PET1 is laminated on the coating film in the direction where the inorganic layer contacts the coating film, and the first PET1 and the second PET1 are used to sandwich the coating film. In the state, it passed through the heating zone of 100 degreeC for 3 minutes, conveying continuously. Thereafter, it was cured by irradiating ultraviolet light with a 160 W / cm air-cooled metal halide lamp (manufactured by EYE GRAPHICS CO., LTD.), to form a wavelength conversion layer containing quantum dots. The amount of ultraviolet radiation is 2000mJ / cm 2 .

Embodiment 2~6 and comparative example 1~4

[0190] Wavelength converting members of other examples and comparative examples were fabricated in the same manner as in Example 1 except that the base film or barrier layer was changed to those described in Table 1.

[0191] (Evaluation of Brightness)

[0192] A commercially available tablet terminal (manufactured by Amazon.com, Inc., Kindle Fire HDX 7") was disassembled, and QDEF (quantum dot film manufactured by 3M Company) was taken out from the backlight unit, and the examples and comparisons cut in a rectangular shape were assembled. Example wavelength conversion member was used instead of QDEF. In this way, a liquid crystal display device was fabricated.

[0193] The produced liquid crystal display device was turned on so that the entire surface displayed white, and measured with a luminance meter (SR3, manufactured by TOPCON CORPORATION) installed at a position 740 mm vertical to the surface of the light guide plate. The measurement results are shown in Table 1.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorptance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| absorptance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com