Method for producing seedling and cultivation media from waste agaric sticks

A technology of cultivation substrate and Agaric fungus, which is applied in the field of preparation of cultivation substrate for seedling cultivation, can solve problems such as lack of methods, and achieve the effects of wide sources of process raw materials, environmental protection, and improvement of water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

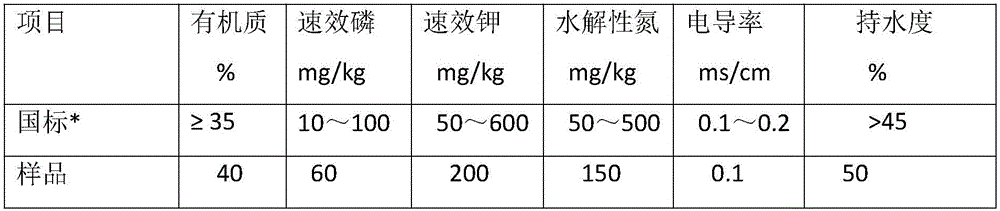

[0024] The collected discarded fungus sticks are peeled off the outer plastic packaging bag; then they are crushed, and in the crushed discarded fungus sticks, the volume ratio is 60%: 30%: 10%. , peat, chicken manure mixed evenly. Then, add yeast and bacillus to the mixed material, wherein the mass ratio of yeast and bacillus is 2:1, and the total amount of yeast and bacillus added is 0.1% of the material volume, and then stacked and fermented, covered outside the pile Plastic film makes the temperature in the heap rise, and keeps the temperature at 45°C. During the fermentation process, the moisture is kept at 60%, and fermented for 20 days, wherein the primary substrate is obtained by turning and throwing once every 5 days. Then in the primary substrate, add sodium dodecylbenzenesulfonate and vermiculite, its addition is respectively 2% and 6% of the primary substrate volume, after mixing evenly, promptly obtains seedling cultivation cultivation substrate (table 1), its pur...

Embodiment 2

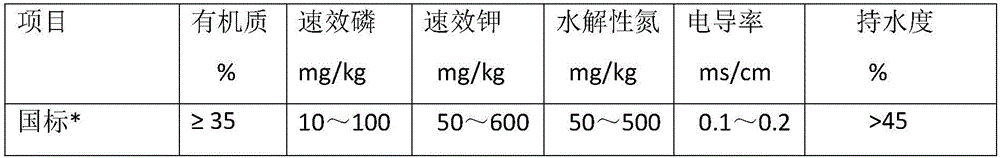

[0029] The collected discarded fungus sticks are peeled off the plastic packaging bag of its outer layer; then it is pulverized, and in the pulverized discarded fungus sticks, the volume content ratio is 40%: 50%: 10%, the fungus sticks , peat, chicken manure mixed evenly. Then add yeast and bacillus to the mixed material, wherein the mass ratio of yeast and bacillus is 2:1, and the total amount of yeast and bacillus added is 1% of the material volume, and then stacked and fermented, covered outside the pile Plastic film makes the temperature in the heap rise and keeps the temperature at 60°C. During the fermentation process, the moisture is kept at 60%, and the fermentation is carried out for 25 days, wherein the primary substrate is obtained by turning and throwing once every 5 days. Then in primary substrate, add sodium dodecylbenzene sulfonate and vermiculite, its addition is respectively 4% and 3% of primary substrate volume, after mixing uniformly, namely obtain seedling...

Embodiment 3

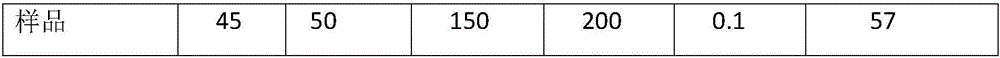

[0035] The collected discarded fungus sticks are peeled off the outer plastic packaging bag; then they are crushed, and in the crushed discarded fungus sticks, the volume ratio is 50%: 30%: 20%. , peat, chicken manure mixed evenly. Then add yeast and bacillus to the mixed material, wherein the mass ratio of yeast and bacillus is 2:1, and the total amount of yeast and bacillus added is 0.6% of the material volume, and then stacked and fermented, covered outside the pile A plastic film is used to raise the temperature in the heap and keep the temperature at 50°C. During the fermentation process, the moisture is maintained at 60%, and the fermentation is carried out for 25 days, wherein the primary substrate is obtained by turning and throwing once every 5 days. Then, in the primary substrate, polyethylene glycol and vermiculite were added in an amount of 3% and 5% of the volume of the primary substrate respectively. After mixing evenly, the seedling cultivation substrate (Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com