Edible plural gel blast cereal sauce and preparation method thereof

A technology of compound gel and cereal sauce, applied in the fields of food science, food ingredients as gelling agent, application, etc., can solve the problems of sauce penetration, high storage cost, short shelf life, etc., and achieve good chewing and sensory, The effect of improving product texture and improving gel texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

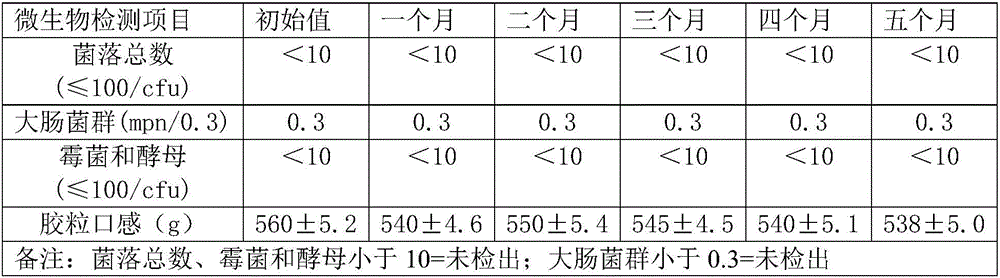

Embodiment 1

[0038] Embodiment 1 Edible composite hydrophilic polysaccharide black rice sauce product

[0039] (1) Compound hydrophilic polysaccharide colloid preparation: mix 9kg sodium alginate, 12kg i-carrageenan, 6kg gelatin, and 6kg pregelatinized starch, then add 567kg warm water (55°C), and carry out cyclic shearing through a colloid mill until it forms Uniform glue solution, keep warm at 55°C after preparation;

[0040] (2) Composite liquid preparation: Dissolve 7.5kg calcium chloride powder with 120kg water, then add 22.5kg fructose syrup and mix evenly for later use;

[0041] (3) Black rice pretreatment: 30kg of black rice is dropped into the composite solution that step (2) makes, 75 ℃ of heating 15 minutes;

[0042] (4) Granulation reaction: filter the black rice after the pretreatment in step (3) to remove the complex solution, then disperse, drop into the composite hydrophilic polysaccharide colloid prepared in step (1) and carry out gel reaction for 5 minutes.

[0043] (5)...

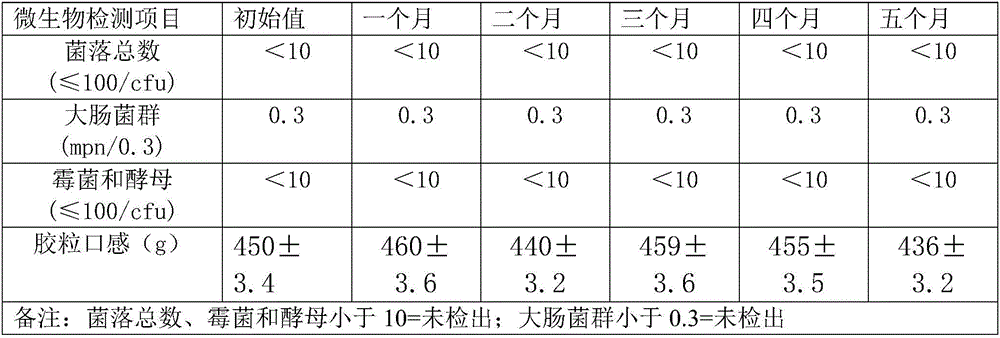

Embodiment 2

[0055] Embodiment 2 Edible compound hydrophilic polysaccharide coix seed colloid product

[0056] (1) Compound hydrophilic polysaccharide colloid preparation: mix 3kg sodium alginate, 3kg i-carrageenan, 6kg gelatin, and 6kg denatured starch, then add 582kg warm water (55°C), and carry out cyclic shearing through a colloid mill until a uniform gel is formed Glue solution, keep warm at 55°C after preparation;

[0057] (2) Composite liquid preparation: Dissolve 45kg of calcium chloride powder with 90kg of water, then add 15kg of fructose syrup and mix evenly for subsequent use;

[0058] (3) Barley pretreatment: put 30kg of barley into the compound solution prepared in step (2), and heat at 80°C for 30 minutes;

[0059] (4) Granulation reaction: filter the pretreated barley in step (3) to remove the compound solution, then disperse it, and put it into the compound hydrophilic polysaccharide colloid prepared in step (1) to carry out gel reaction, and react for 10 minutes;

[0060...

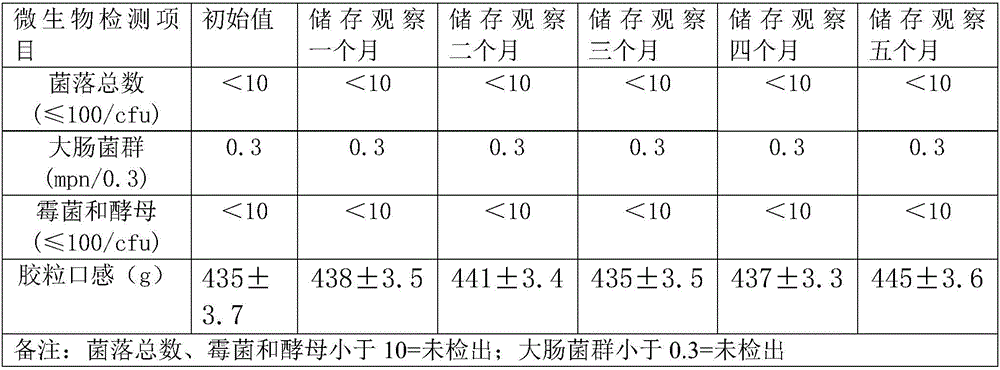

Embodiment 3

[0070] Embodiment 3 Edible composite hydrophilic polysaccharide oatmeal product

[0071] (1) Compound hydrophilic polysaccharide colloid preparation: Mix 3kg sodium alginate, 3kg i-carrageenan, 6kg gelatin, and 60kg denatured starch, add 528kg warm water (55°C) quantitatively, and carry out cyclic shearing through a colloid mill until a uniform gel is formed Glue solution, keep warm at 55°C after preparation;

[0072] (2) Composite liquid preparation: Dissolve 7.5kg calcium chloride powder with 97.5kg water, then add 45kg fructose syrup and mix evenly for subsequent use;

[0073] (3) Oat pretreatment: put 30kg of oat into the composite solution prepared in step (2), and heat at 85°C for 20 minutes;

[0074] (4) Granulation reaction: filter the oat after step (3) pretreatment to remove the composite liquid, then disperse, and drop into the composite hydrophilic polysaccharide colloid prepared in step (1) to carry out gel reaction, and react for 10 minutes;

[0075] (5) Cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com