Regenerative natural gas boiler energy-saving denitration integrated system

A natural gas and heat storage technology, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of low denitrification efficiency, high exhaust gas temperature, and high nitrogen oxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

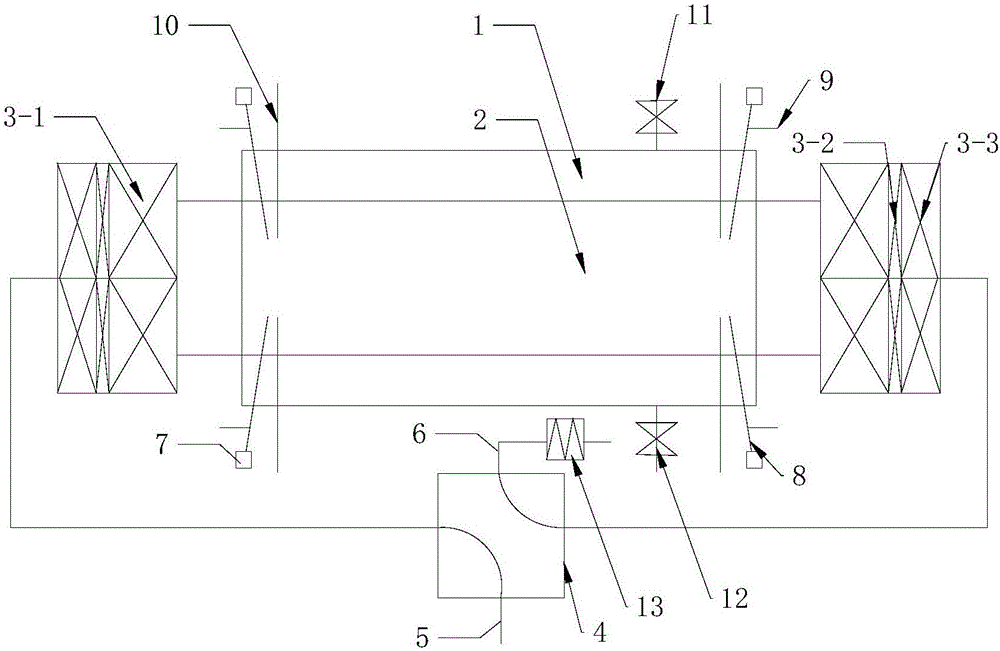

[0020] Such as figure 1 As shown, the regenerative natural gas boiler energy-saving and denitrification integrated system of the present invention includes:

[0021] Boiler body 1, I-shaped tube combustion chamber 2, two sets of regenerative natural gas burners, and condenser 13, of which:

[0022] The I-shaped tube combustion chamber 2 is located inside the boiler body 1, and the SNCR reaction occurs in the I-shaped tube combustion chamber 2;

[0023] Both ends of the boiler body 1 are respectively provided with two gas pipelines 10 extending into the I-shaped tube combustion chamber 2;

[0024] Both ends of the boiler body 1 are respectively provided with two reducing agent pipelines 8 extending into the I-shaped tube combustion chamber 2, which are connected with the reducing agent control valve 7 and the compressed air pipeline 9, and the reducing agent input from the reducing agent control valve 7 The reducing agent is injected into the I-shaped tube combustion chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com