Polysilicon waste gas treatment and waste heat utilization device and process

A waste gas treatment and polysilicon technology, applied in the direction of halosilane, silicon compound, heat exchanger type, etc., can solve the problems of polysilicon output and product quality, consumption of large lye, waste of chlorosilane materials, etc., to prevent fire and Explosion accidents, consumption reduction, and stability assurance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

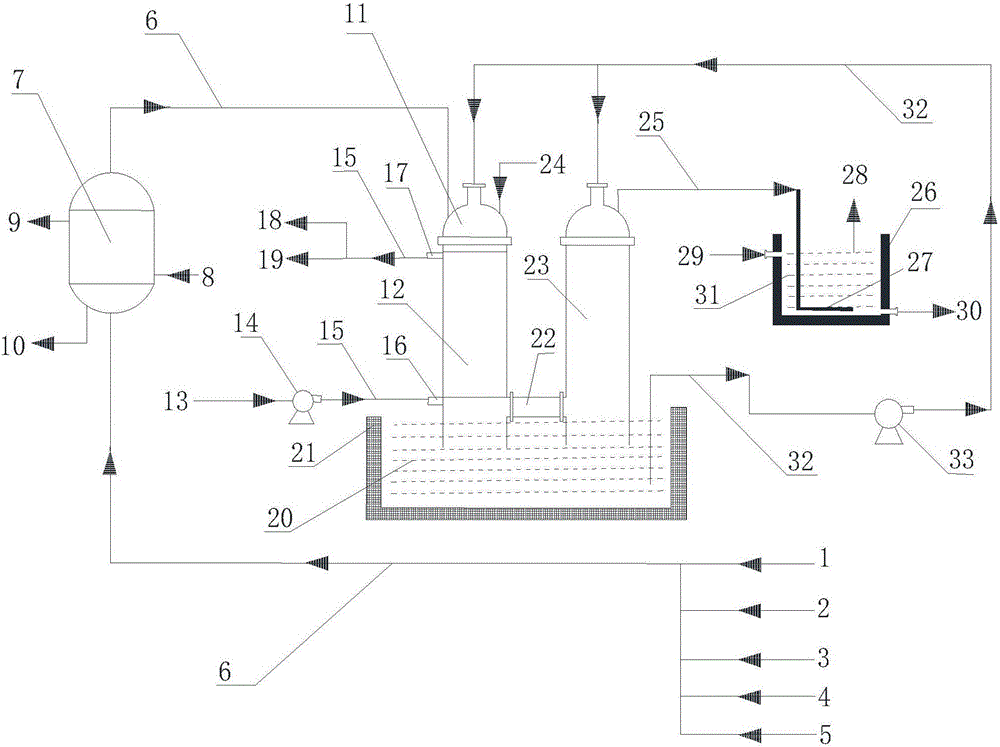

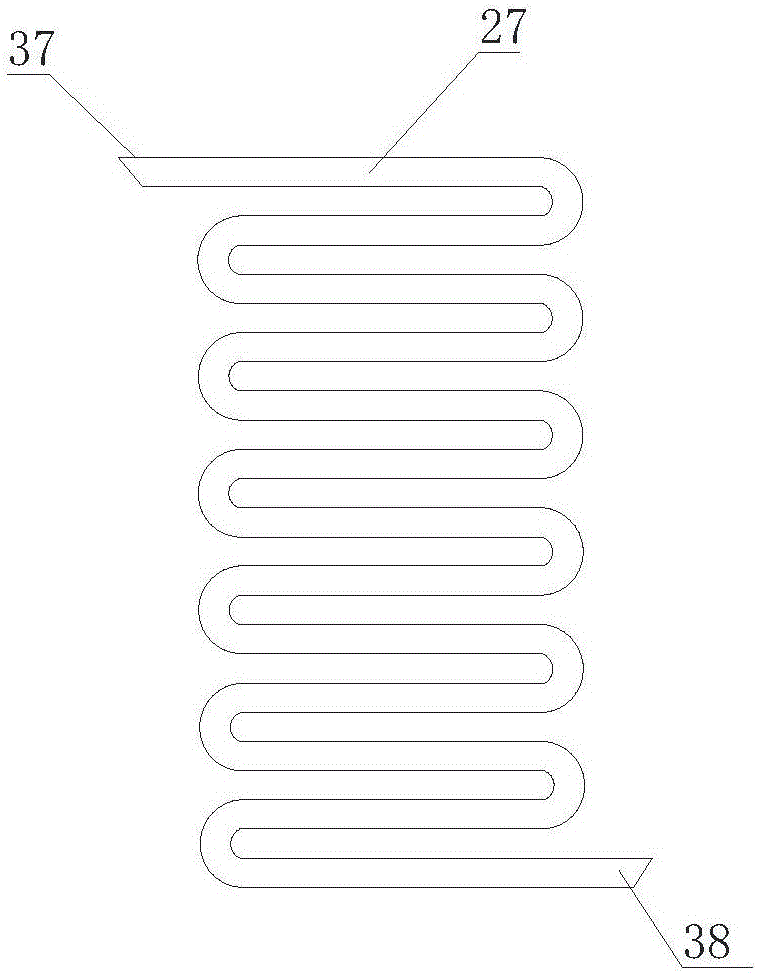

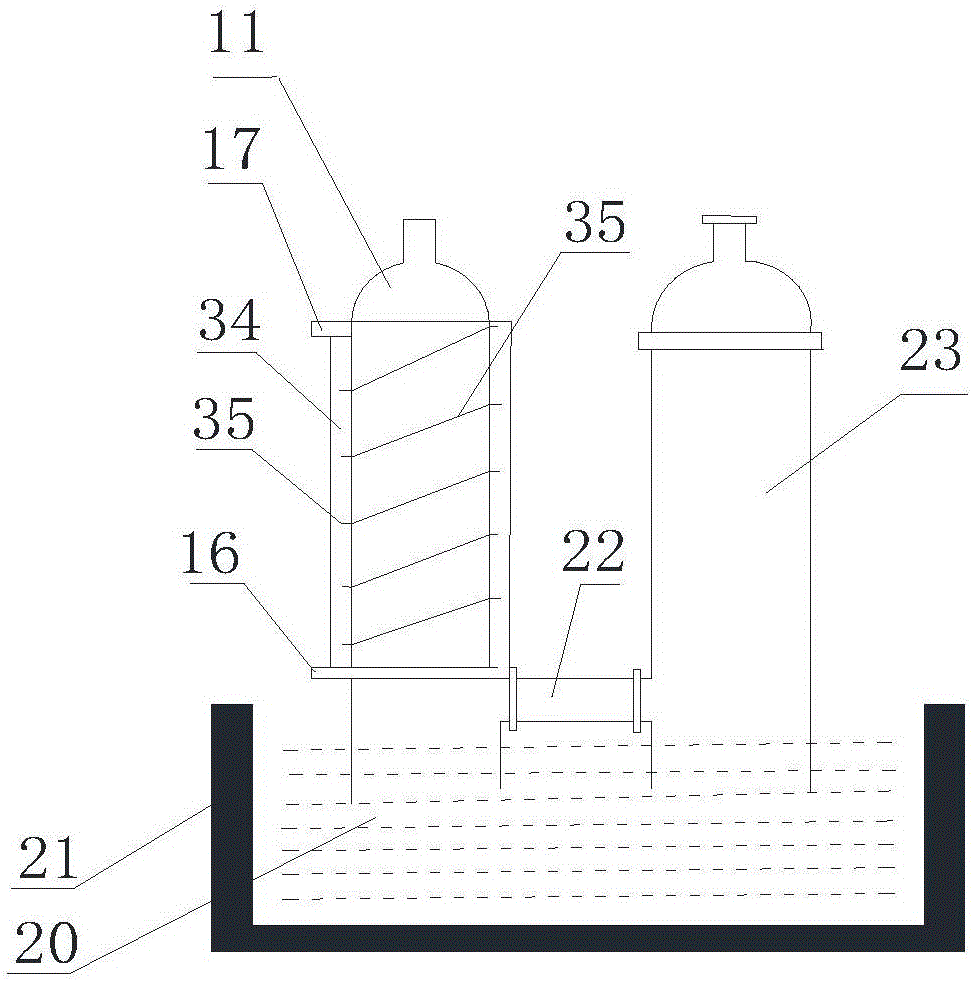

[0038] Reference Figure 1-4 , A polysilicon waste gas treatment and waste heat utilization device, including waste gas condensation recovery tank 7, waste gas leaching tower A11, waste gas leaching tower B23, lye tank 21 and liquid sealed water tank 26, said waste gas condensation recovery tank 7 is connected in series In the exhaust gas pipe 6 used for exhaust gas collection, the end of the exhaust pipe 6 is connected to the exhaust gas washing tower A11, the bottom of the exhaust gas washing tower A11 is set in the lye tank 21, and the exhaust gas washing tower A11 is connected by a connecting pipe 22 The exhaust gas leaching tower B23, the bottom of the exhaust gas leaching tower B23 is arranged in the lye pool 21, the exhaust gas leaching tower B23 is connected to the vent pipe 27 arranged in the liquid-sealed water tank 26 through the exhaust pipe 25; the lye pool 21 is also connected to the bottom of the waste gas leaching tower A11 and the waste gas leaching tower B23 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| autoignition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com