A kind of composite catalyst and its preparation method and application

A composite catalyst, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical elements of heterogeneous catalysts, etc., can solve the problems of lack and lack of heterogeneous supercritical water oxidation catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

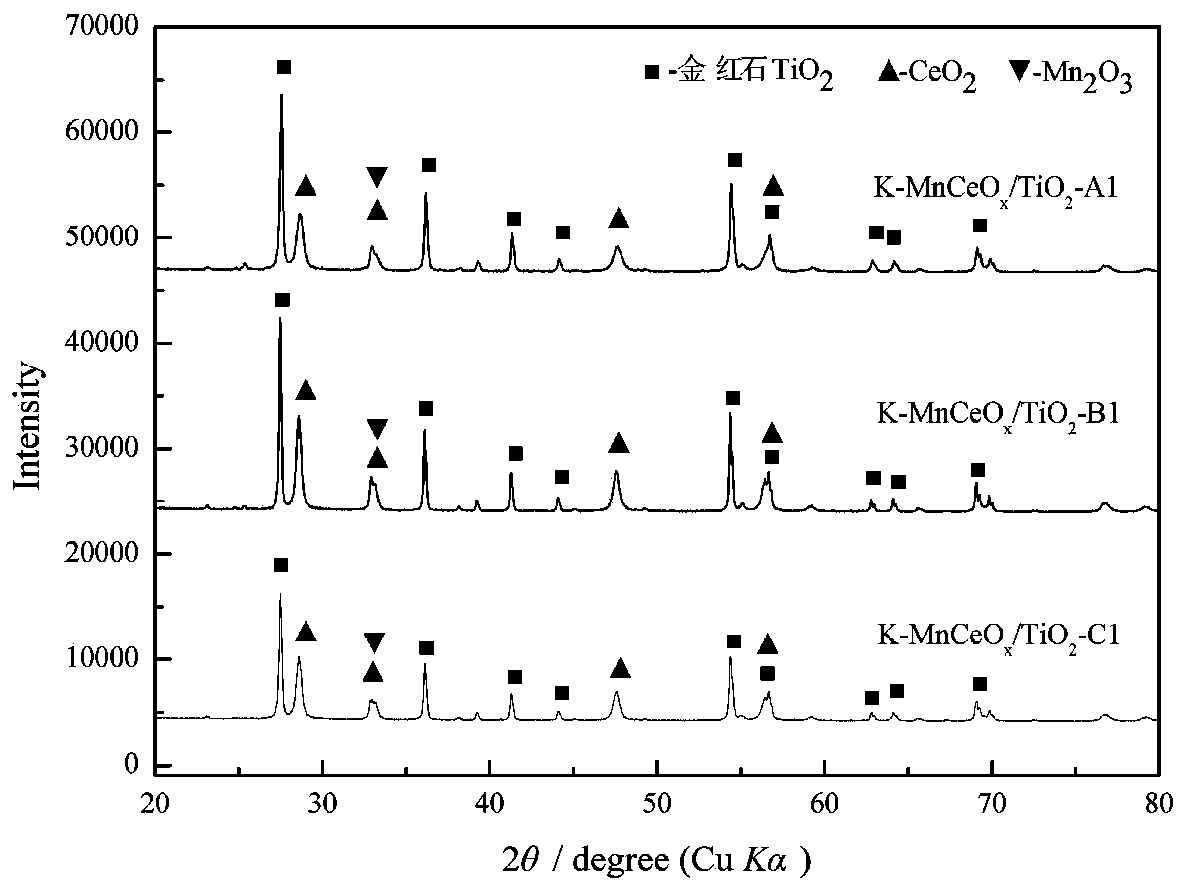

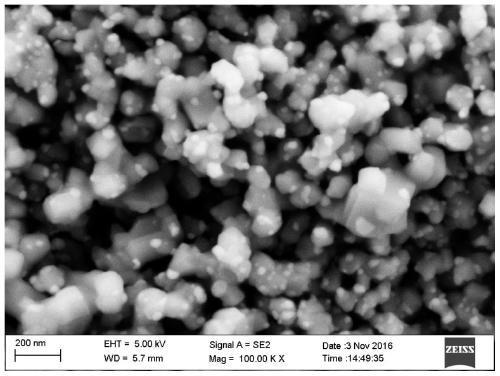

[0069] In this example, TiCl 4 , Ce(NO 3 ) 3 , Mn(NO 3 ) 2 、KNO 3 and ammonia water as raw materials, the composite catalyst is prepared by co-precipitation method, comprising the following steps:

[0070] (1) Formulated with Ce 3+ Ionic metal salts, Mn 2+ Ionic metal salts and K + Ion metal salt solution: add Ce(NO 3 ) 3 , Mn(NO 3 ) 2 、KNO 3 to deionized water;

[0071] (2) Under ice-water bath conditions, slowly drop analytical pure TiCl into the metal salt solution obtained in step (1) 4 Liquid, control (Mn+Ce) / Ti molar ratio 1:9, TiO 2 Concentration 0.05~0.5mol / L, TiCl 4 with H 2 O reacts to generate HCl and TiO 2 And release a lot of heat; the prepared aqueous solution was ultrasonically oscillated with 450W power for 60min, left to age for 24h; then vigorously stirred at a speed of 300r / min, and ammonia water was added to adjust the pH to 10.0. Shaking for 24 hours, standing and aging for 12 hours.

[0072] (3) After aging in step (2), filter and wash ...

Embodiment 2

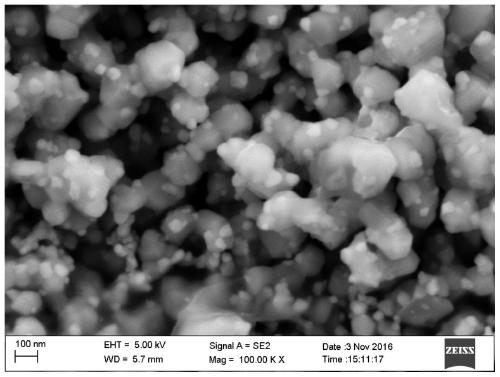

[0077] In this example, TiCl 4 , CeCl 3 , MnCl 2 , KCl and ammoniacal liquor are raw materials, and adopt co-precipitation method to prepare composite catalyst, comprise the following steps:

[0078] (1) Formulated with Ce 3+ Ionic metal salts, Mn 2+ Ionic metal salts and K + Ionic metal salt solution: add CeCl at the ratio of Ce / Mn molar ratio 2:3, K / Mn molar ratio 1:1 3 , MnCl 2 , KCl to deionized water;

[0079] (2) Under ice-water bath conditions, slowly drop analytical pure TiCl into the metal salt solution obtained in step (1) 4 Liquid, control (Mn+Ce) / Ti molar ratio 1:9, TiO 2 Concentration 0.05~0.5mol / L, TiCl 4 with H 2 O reacts to generate HCl and TiO 2 and release a lot of heat; the prepared aqueous solution was ultrasonically oscillated at 650W for 30min, and left to age for 12h; then vigorously stirred at a speed of 150r / min, and ammonia water was added to adjust the pH to 8.0. Shake at constant temperature for 48 hours, and stand and age for 24 hours. ...

Embodiment 3

[0085] In this example, TiCl 4 , Ce(NO 3 ) 3 , Mn(NO 3 ) 2 、KNO 3 And ammonia water is raw material, adopts impregnation method to prepare composite catalyst, comprises the following steps:

[0086] (1) Formulated with Ce 3+ Ionic metal salts, Mn 2+ Ionic metal salts and K + Metal salt solution of ions: Add Ce(NO 3 ) 3 , Mn(NO 3 ) 2 、KNO 3 to deionized water;

[0087] (2) Under ice-water bath conditions, the analytically pure TiCl 4 The liquid is slowly dropped into deionized water to generate TiO 2 , TiCl 4 with H 2 O reacts to generate HCl and TiO 2 And release a lot of heat, control TiO 2 Concentration 0.05~0.5mol / L, the prepared TiO 2 The aqueous solution was ultrasonically oscillated with a power of 650W for 30min, and left to age for 24h to obtain TiO 2 The clarified aqueous solution, and then add ammonia water, while stirring vigorously at a speed of 300r / min, until the pH is 8.0, to obtain a TiO-containing 2 The emulsion was filtered and washed, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com