MoS2/In2S3 composite catalyst serving as photoelectrocatalytic dehydrogenation material and preparation method of MoS2/In2S3 composite catalyst

A composite catalyst, photoelectric catalysis technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of rare and widespread application, high price, reduced photoelectric hydrogen evolution performance, etc., and achieve wide application prospects , the process is simple, the effect of excellent photoelectric catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

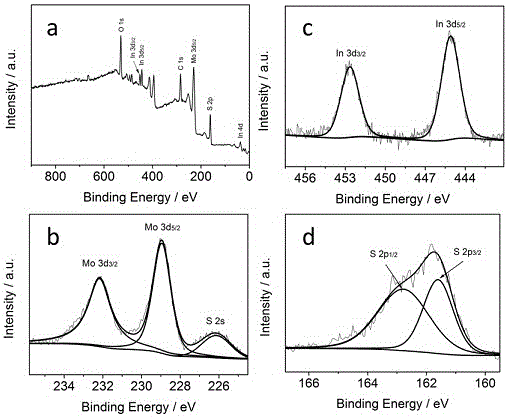

Method used

Image

Examples

Embodiment 1

[0035] (1) Weigh 0.015g of sodium molybdate dihydrate and 0.0266g of indium chloride (molar ratio 1:2) and dissolve them in 20ml of deionized water;

[0036] (2) Weigh 0.03g of thioacetamide into the solution of step (1), stir well and then sonicate for 30min;

[0037] (3) Transfer the solution prepared in step (2) to the polytetrafluoroethylene lining of a 25ml hydrothermal kettle, place the pretreated ITO glass in the inner tank with the conductive side facing down, and put the hydrothermal kettle and inner tank After the lining is sealed, the temperature of the hydrothermal kettle is controlled at 220ºC, and the hydrothermal time is controlled at 20h to obtain MoS with good adhesion 2 / In 2 S 3 Composite catalyst;

[0038] (4) Take out the ITO glass and soak it in absolute ethanol and deionized water for 15 minutes, then dry it to obtain MoS 2 / In 2 S 3 Composite catalyst.

[0039] Simple MoS 2 Preparation: Weigh 0.015g of sodium molybdate dihydrate and 0.03g of thi...

Embodiment 2

[0042] (1) Weigh 0.015g of sodium molybdate dihydrate and 0.0665g of indium chloride (molar ratio 1:5) and dissolve them in 20ml of deionized water;

[0043] (2) Weigh 0.03g of thioacetamide and add it to the solution of step 1), stir it evenly and then sonicate for 30min;

[0044] (3) Transfer the solution prepared in step 2) to the polytetrafluoroethylene lining of the hydrothermal kettle, place the pretreated ITO glass in the liner with the conductive side facing down, and seal the hydrothermal kettle and the inner lining Finally, the temperature of the hydrothermal kettle was controlled at 220ºC, and the hydrothermal time was controlled at 20h to obtain MoS with good adhesion. 2 / In 2 S 3 Composite catalyst;

[0045] (4) Take out the ITO glass and soak it in absolute ethanol and deionized water for 15 minutes, then dry it to obtain MoS 2 / In 2 S 3 Composite catalyst.

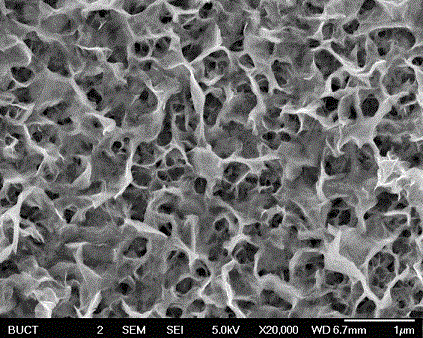

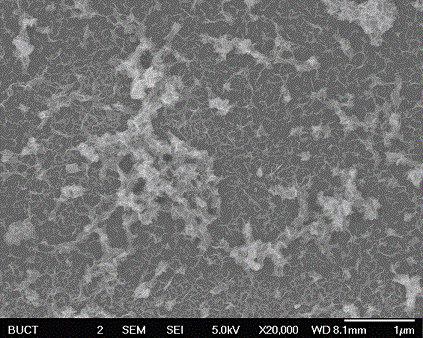

[0046] MoS 2 / In 2 S 3 Scanning electron micrographs of composite catalysts ( Figure 5 ) show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com