Preparation method for ceramic shell for nickel-based superalloy single crystal/directional solidification

A nickel-based high-temperature alloy, directional solidification technology, applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problem of chemical reaction between the surface of the mold shell and the molten alloy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

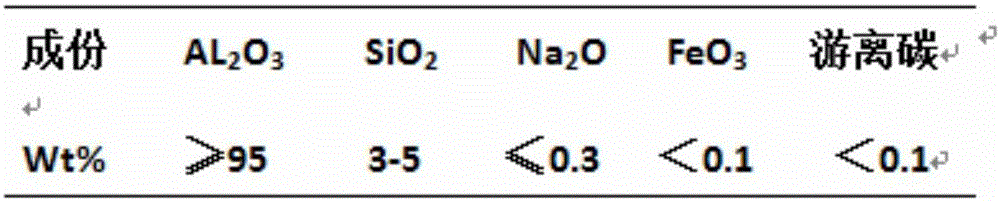

[0028] 1. Prepare the surface coating, prepare EC95 (320 mesh) chemical composition as shown in Table 1, silica sol (830), wetting agent (JFC), defoamer (n-octanol); the preparation ratio is silica sol and The weight ratio of EC95 (320 mesh) is 1:4, the volume of wetting agent and defoaming agent is 0.12% of silica sol; pour a certain amount of silica sol into the paint bucket, and then add wetting agent and defoaming agent in proportion, At the same time, start the mixer and slowly add EC95 (320 mesh) while stirring. After the stirring time is more than 2 hours, measure the viscosity once or twice during the stirring (the viscosity should be slightly higher than the specified viscosity), and then pour it into the L-shaped mixer and continue stirring for 24 hours before use. . The viscosity requirement is 35-40s.

[0029] 2. Prepare the reinforcement layer coating. The ratio of reinforcement layer preparation is about 1:1.60 between silica sol (1430) and EC95 (320 mesh). The ...

Embodiment 2

[0039]1. Prepare the surface coating, prepare the chemical composition of corundum (320 mesh) powder as shown in Table 1, silica sol (830), wetting agent (JFC), defoamer (n-octanol); the preparation ratio is silica sol The weight ratio to corundum powder (320 mesh) is 1:4, and the wetting agent and defoaming agent are both 0.12% by volume of silica sol; pour a certain amount of silica sol into the paint bucket, and then add wetting agent and defoaming agent in proportion At the same time, start the mixer and slowly add corundum powder (320 mesh) while stirring. After stirring for more than 2 hours, measure the viscosity once or twice during stirring (the viscosity should be slightly greater than the specified viscosity) and then pour it into the L-shaped mixer and continue stirring for 24 hours. available later. The viscosity requirement is 35-40s.

[0040] 2. Prepare the reinforcement layer coating. The ratio of reinforcement layer preparation is about 1:1.6 between silica s...

Embodiment 3

[0050] 1. Prepare the surface coating and prepare the chemical composition of corundum (320 mesh) powder as shown in Table 1, aluminum sol, wetting agent (JFC), defoamer (n-octanol); the preparation ratio is aluminum sol and corundum powder (320 mesh) The weight ratio is 1:3.8, the wetting agent and defoaming agent are both aluminum sol volume 0.15%; pour a certain amount of aluminum sol into the paint bucket, and then add wetting agent and defoaming agent in proportion, at the same time Start the mixer and add corundum powder (320 mesh) slowly while stirring. After stirring for more than 2 hours, measure the viscosity once or twice during stirring (the viscosity should be slightly higher than the specified viscosity), then pour it into the L-shaped mixer and continue stirring for 24 hours before use. . The viscosity requirement is 35-40s.

[0051] 2. Prepare the reinforcement layer coating. The ratio of reinforcement layer preparation is about 1:1.7 between silica sol (1430)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com