A kind of co-precursor method normal pressure drying method for preparing bulk silica airgel

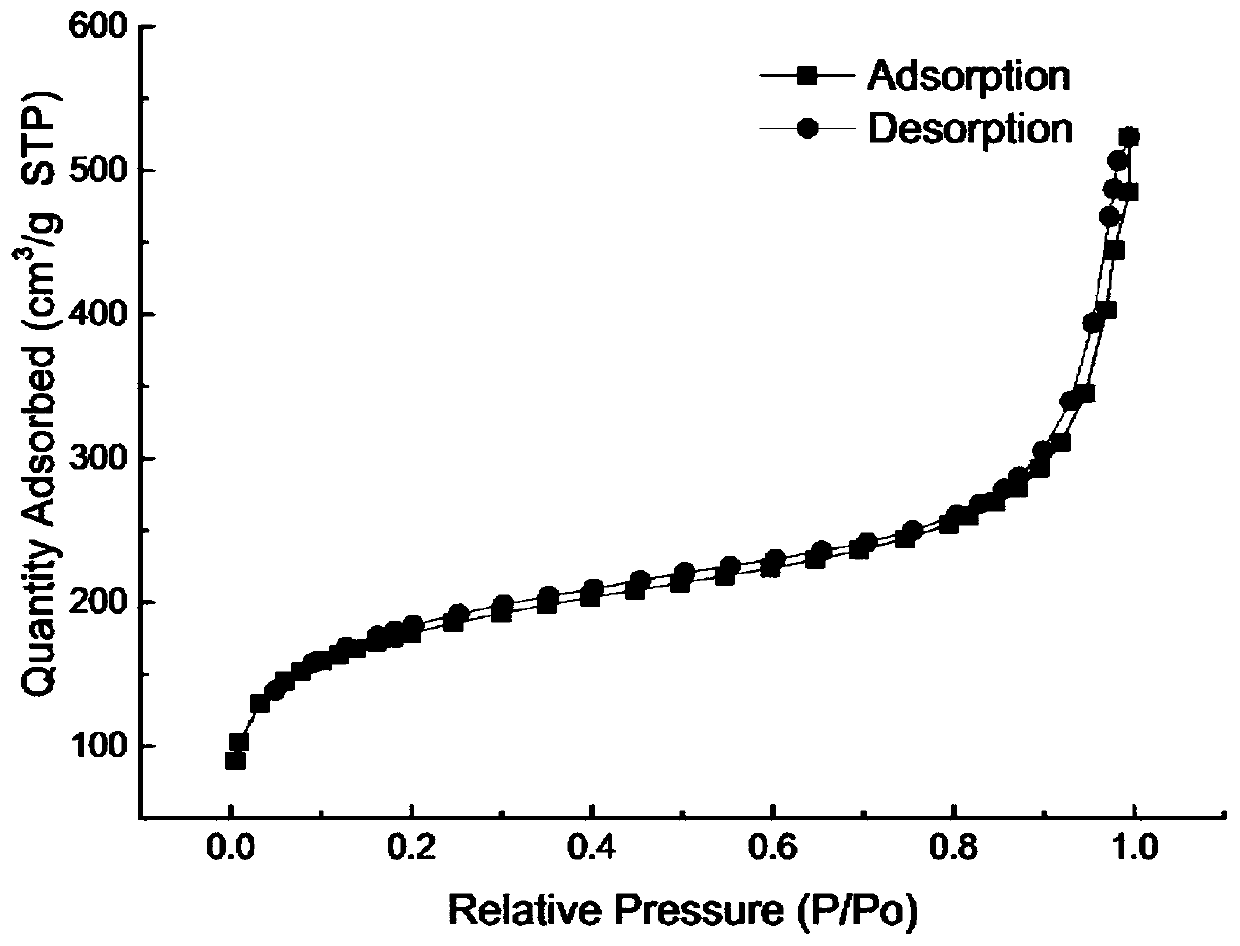

A technology of atmospheric drying and co-precursor, applied in the directions of silicon dioxide, silicon oxide, chemical instruments and methods, etc., can solve the problems of long preparation cycle, unfavorable industrial production, limited application and promotion of aerogel, and fragile network framework. , to achieve the effect of excellent hydrophobicity, good mechanical strength and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of co-precursor method atmospheric pressure drying that the present invention proposes prepares the method for bulk silica airgel, comprises the following steps:

[0044] S1. Preparation of silicon source solution: add 150ml ethanol solvent to 57.5ml tetraethyl orthosilicate, stir well, add 10ml deionized water, stir well to obtain A silicon source solution; add 98ml to 30ml methyltrimethoxysilane ethanol solvent, stir evenly, add 4ml deionized water, stir evenly to obtain B silicon source solution;

[0045] S2. Hydrolysis: Stir the A silicon source solution for 20 minutes and add 0.1mol / L hydrochloric acid during the stirring process, adjust the pH value to 3.5, and then place it in a water bath at 40°C for 5 hours to obtain the hydrolyzed solution of the A silicon source precursor; Stir the silicon source solution for 40 minutes and add 0.01mol / L hydrochloric acid during the stirring process, adjust the pH value to 4.0, and then place it in a water bath at 50°C...

Embodiment 2

[0054] A kind of co-precursor method atmospheric pressure drying that the present invention proposes prepares the method for bulk silica airgel, comprises the following steps:

[0055] S1. Silicon source solution preparation: add 120ml ethanol solvent to 57.5ml tetraethyl orthosilicate, stir well, add 10ml deionized water, stir well to get A silicon source solution; add 125ml to 30ml methyltrimethoxysilane ethanol solvent, stir evenly, add 4ml deionized water, stir evenly to obtain B silicon source solution;

[0056] S2. Hydrolysis: Stir the A silicon source solution for 40 minutes and add 0.1mol / L hydrochloric acid during the stirring process, adjust the pH value to 3.0, and then place it in a water bath at 50°C for 3 hours to obtain the hydrolyzed solution of the A silicon source precursor; Stir the silicon source solution for 20 minutes and add 0.01mol / L hydrochloric acid during the stirring process, adjust the pH value to 4.0, and then place it in a water bath at 40°C for ...

Embodiment 3

[0068] A kind of co-precursor method atmospheric pressure drying that the present invention proposes prepares the method for bulk silica airgel, comprises the following steps:

[0069] S1. Preparation of silicon source solution: add 180ml ethanol solvent to 57.5ml tetraethyl orthosilicate, stir well, add 10ml deionized water, stir well to obtain A silicon source solution; add 75ml to 30ml methyltrimethoxysilane ethanol solvent, stir evenly, add 4ml deionized water, stir evenly to obtain B silicon source solution;

[0070] S2. Hydrolysis: Stir the A silicon source solution for 25 minutes and add 0.1mol / L hydrochloric acid during the stirring process, adjust the pH value to 3.5, and then place it in a water bath at 45°C for 4 hours to obtain the hydrolyzed solution of the A silicon source precursor; Stir the silicon source solution for 25 minutes and add 0.01mol / L hydrochloric acid during the stirring process, adjust the pH value to 4.0, and then place it in a water bath at 48°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com