Device for preparing magnetic nanoparticles through parallel high-temperature pyrolysis and application

A magnetic nanoparticle, high-temperature pyrolysis technology, applied in nanotechnology, ferrous oxides, inorganic chemistry, etc., can solve problems such as poor batch consistency, uneven heat and mass transfer, and uneven nanoparticle size. , to achieve uniform size, good product consistency, and ensure the consistency of reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

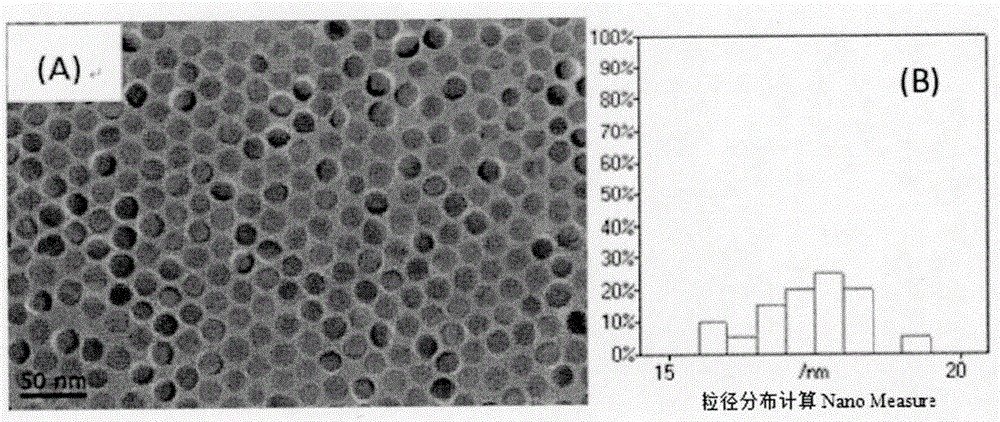

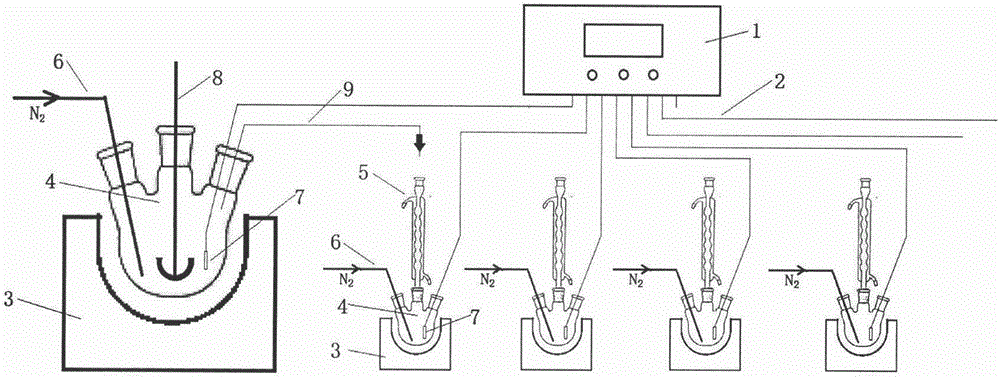

[0026] Example 1, five 100mL parallel electric heating reactor devices to prepare manganese zinc ferrite magnetic nanoparticles

[0027] The preparation device consists of a 0.5L material mixing pretreatment electric heating reactor, 5 parallel electric heating programmed temperature reactors (0.1L) and a programmed temperature controller. The preparation process is as follows:

[0028] (1) Add 0.2L dioctyl ether to the material mixing pretreatment reactor, and continuously feed nitrogen to remove oxygen in the system; add 20mmol of iron acetylacetonate, 6mmol of manganese acetylacetonate, 4mmol of zinc acetylacetonate, and The ratio of oleic acid and oleylamine (respectively 10:2, 7:5, 5:7, the total amount is 120mmol) was heated to 110°C at a heating rate of 3°C / min by a programmed temperature control device under nitrogen gas feed conditions. ℃, to fully remove the lower boiling water and impurities in the solution, and at the same time make the acetylacetonate complex, ol...

Embodiment 2

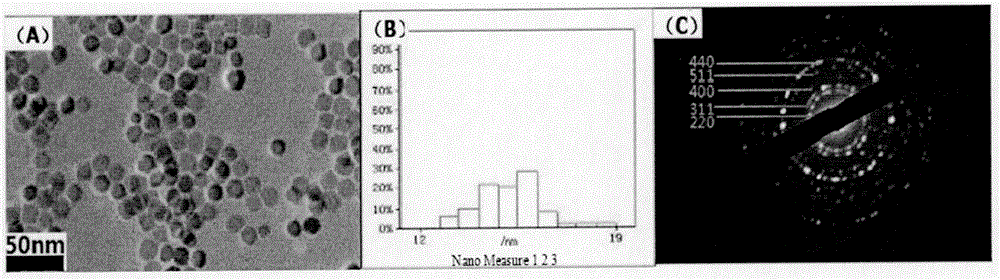

[0032] Example 2, five 250mL parallel electric heating reactor devices to prepare zinc ferrite magnetic nanoparticles

[0033] The preparation device consists of a 1L material mixing pretreatment electric heating reactor, 5 parallel electric heating programmed temperature reactors (0.25L) and a programmed temperature rise controller. The preparation process is as follows:

[0034](1) Add 0.5L dibenzyl ether in the material mixing pretreatment reactor, and continuously feed nitrogen to remove oxygen in the system; add 180mmol iron acetylacetonate, 90mmol zinc acetylacetonate and 700mmol oleic acid, Under the conditions, the heating rate of 8°C / min is heated to 120°C by the program temperature control device to fully remove the water and impurities with lower boiling points in the solution, and at the same time, the acetylacetone complex, oleic acid, and oleylamine are completely mixed and kept The temperature is 1h.

[0035] (2) The materials that come out of the material mix...

Embodiment 3、10

[0038] Example 3, Ten 500mL Parallel Electric Heating Reactor Devices Prepare Ferroferric Oxide Magnetic Nanoparticles

[0039] The preparation device consists of a 5L material mixing pretreatment electric heating reactor, 10 parallel electric heating programmed temperature reactors (0.5L) and a programmed temperature rise controller. The preparation process is as follows:

[0040] (1) Add 2L dibenzyl ether in the material mixing pretreatment reactor, continue feeding nitrogen to remove the oxygen in the system; Add 300mmol of iron acetylacetonate and oleic acid and oleylamine of 10:2 molar ratio (total amount is 1200mmol), under the condition of feeding nitrogen, heated to 110°C by a programmed temperature control device at a heating rate of 3.3°C / min, so as to fully remove water and impurities with lower boiling points in the solution, and simultaneously make the acetylacetone complex and oleic acid, The oleylamine was mixed completely and kept at this temperature for 1h. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com