Continuous photocatalysis method based on secondary-assembled graphene/P25 composite film

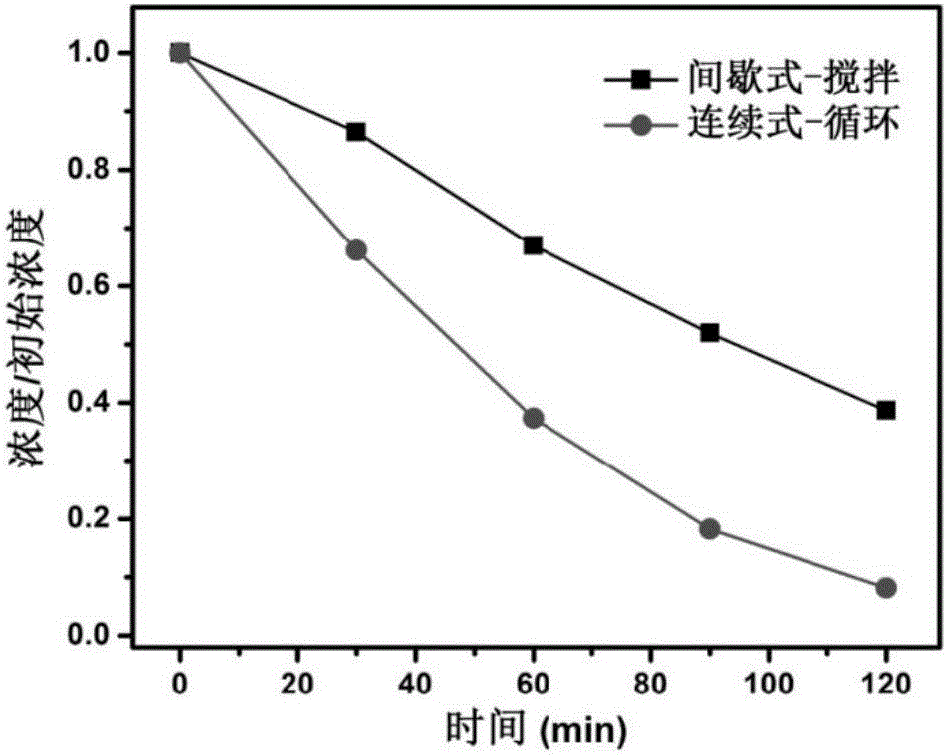

A composite film, two-level assembly technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of inability to meet large-scale industrial-scale treatment of waste liquid, and improve the photocatalytic degradation performance. , The effect of inhibiting agglomeration and facilitating operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

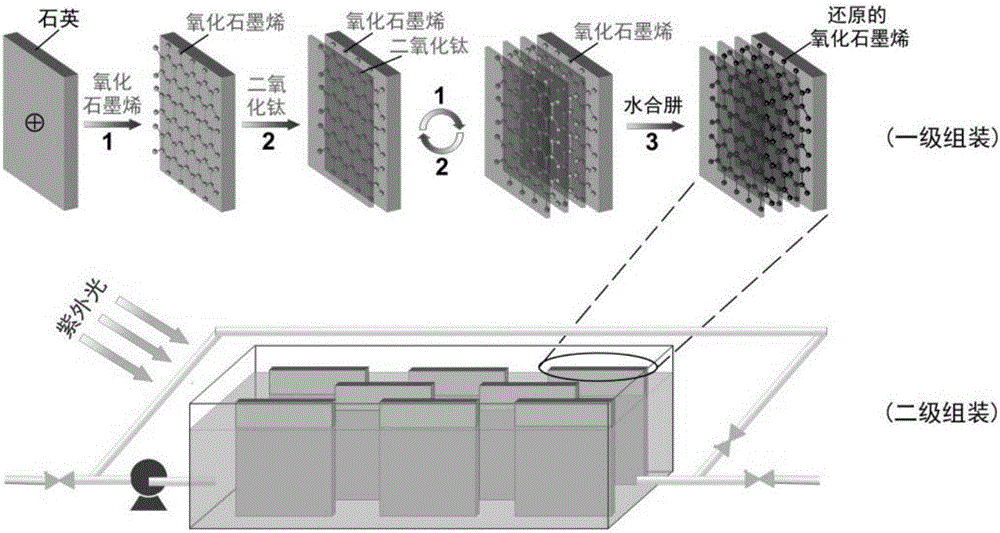

[0020] Specific embodiment one: a kind of continuous photocatalytic method based on secondary assembled graphene / P25 composite film of the present embodiment is specifically carried out according to the following steps:

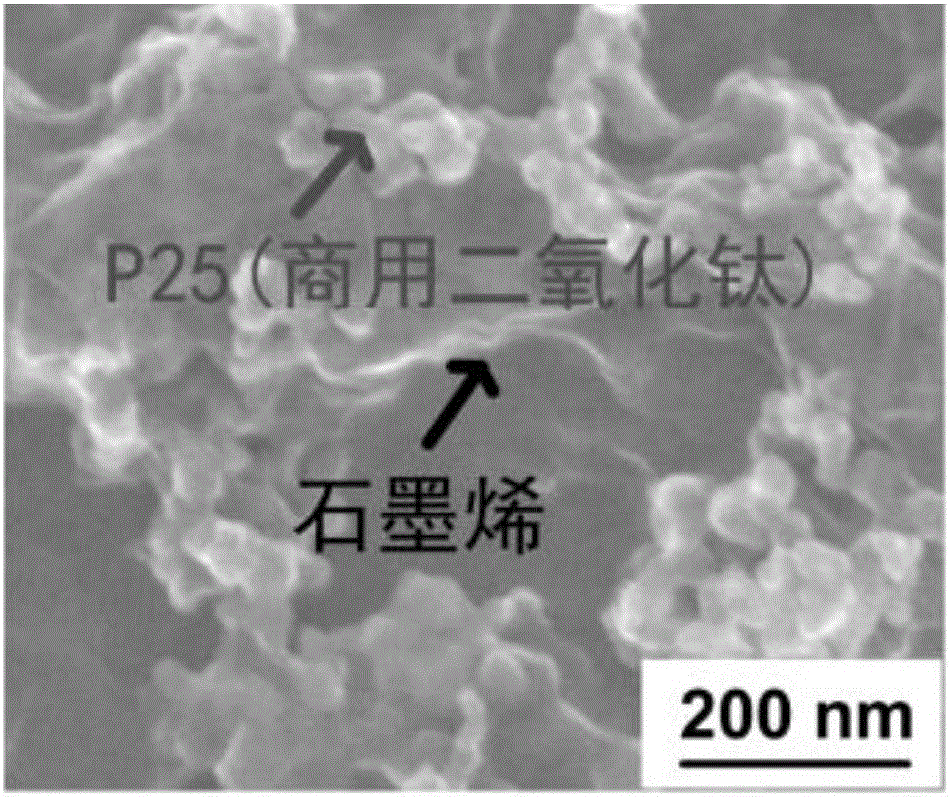

[0021] 1. Assemble the graphene / P25 multilayer film on the quartz sheet by layer-by-layer technology: disperse P25 in a hydrochloric acid solution with a pH of 2, and ultrasonically treat it for 20-60 minutes to obtain a positively charged P25 dispersion; it will be passed through Hummer's The graphene oxide prepared by the method was configured into a 2mg / mL solution by an ultrasonic-assisted method; the clean quartz substrate was immersed in the polyethyleneimine solution for 30min to 60min to obtain a positively charged quartz substrate; The positively charged quartz substrate is immersed in the graphene oxide solution and the P25 dispersion in turn, rinsed with deionized water and dried with nitrogen after each immersion, to obtain a quartz sheet loaded wi...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume ratio of the mass of P25 titanium dioxide described in step 1 to the hydrochloric acid solution with a pH of 2 is 1mg:2mL. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the above steps described in Step 1 are repeated to obtain a quartz plate loaded with a composite thin film with 5 layers. Other steps and parameters are the same as those in Embodiment 1 or 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com