Cyclic utilization and treatment method of fracturing backflow liquid

A fracturing flowback fluid and treatment method technology, applied in mining wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. The effect of reducing dosage, eliminating adverse effects, and wide sterilization range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

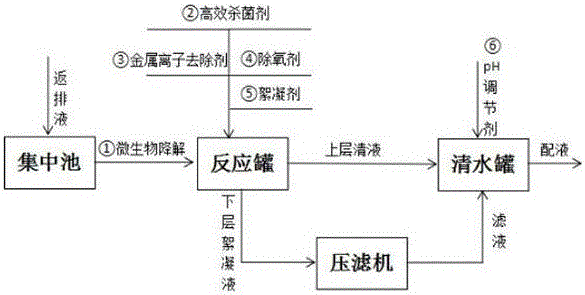

Method used

Image

Examples

Embodiment 1

[0036] Example 1: 300m of flowback fluid in Block Su 59 3 , the water quality is black and smelly, 170s -1 The lower initial viscosity is 7mPa·s. Add 0.45% microorganisms and let stand for 3 days, 170s -1 The lower initial viscosity is 1.2mPa·s; Add 0.15% high-efficiency fungicide into the reaction tank and stir for 20 minutes; Add 0.1% metal ion remover and stir for 5 minutes until pH = 8; Add 0.1% oxygen scavenger and stir for 10 minutes; Add 60ppm of flocculant and stir for 10 minutes, flocculate and settle for 25 minutes, the supernatant liquid is transferred to the clean water tank, the lower layer of flocculant liquid enters the filter press for filtration, and the filtrate is transferred to the clean water tank; Add 0.01% pH adjuster to the supernatant to inhibit cross-linking.

[0037]The microorganisms are obtained by mixing 40-50% of the fracturing flowback fluid, 35-45% of the guar gum solution, and 5-25% of domestic sewage; Methyl benzyl ammonium chlor...

Embodiment 2

[0039] Example 2: 500m of flowback fluid in Tao 7 block 3 , the water quality is black and smelly, 170s -1 The lower initial viscosity is 6mPa·s. Add 0.8% microorganisms and let stand for 2 days, 170s -1 The lower initial viscosity is 1mPa·s; Add 0.12% high-efficiency fungicide into the reaction tank and stir for 25 minutes; Add 0.05% metal ion remover, stir for 5 minutes, until pH = 8.5; Add 0.1% oxygen scavenger and stir for 5 minutes; Add 10ppm flocculant and stir for 15 minutes, flocculate and settle for 30 minutes, the supernatant liquid is transferred to the clean water tank, the lower layer flocculant is filtered into the filter press, and the filtrate is transferred to the clean water tank; Add 0.02% pH adjuster to the supernatant to inhibit cross-linking.

[0040] The microorganisms are obtained by culturing the fracturing flowback fluid, and the high-efficiency fungicide is composed of hydrogen peroxide and dodecyldimethylbenzyl ammonium chloride; hydroge...

Embodiment 3

[0042] Example 3: 430m of flowback fluid in Block Su 5 3 , the water quality is black, smelly and turbid, 170s -1 The lower initial viscosity is 8mPa·s. Add 0.1% microorganisms and let stand for 5 days, 170s -1 The lower initial viscosity is 1.1mPa·s; Add 0.3% high-efficiency fungicide into the reaction tank and stir for 15 minutes; Add 0.5% metal ion remover and stir for 10 minutes until pH = 9; Add 0.2% oxygen scavenger and stir for 10 minutes; Add 100ppm flocculant and stir for 15 minutes, flocculate and settle for 25 minutes, the supernatant liquid is transferred to the clean water tank, the lower layer flocculated liquid enters the filter press for filtration, and the filtrate is transferred to the clean water tank; Add 0.03% pH adjuster to the supernatant to inhibit cross-linking.

[0043] Described microorganism is cultivated after mixing 50% of guar gum solution and 50% of river water, and described high-efficiency bactericide is made up of hydrogen peroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com