Cement-based high-permeability crystalline masterbatch concrete and preparation method thereof

A high-permeability, cement-based technology, applied in the new production process of concrete, can solve the problems of inability to block capillary pores and poor permeability, achieve excellent secondary impermeability, strong permeability, and improve self-healing. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

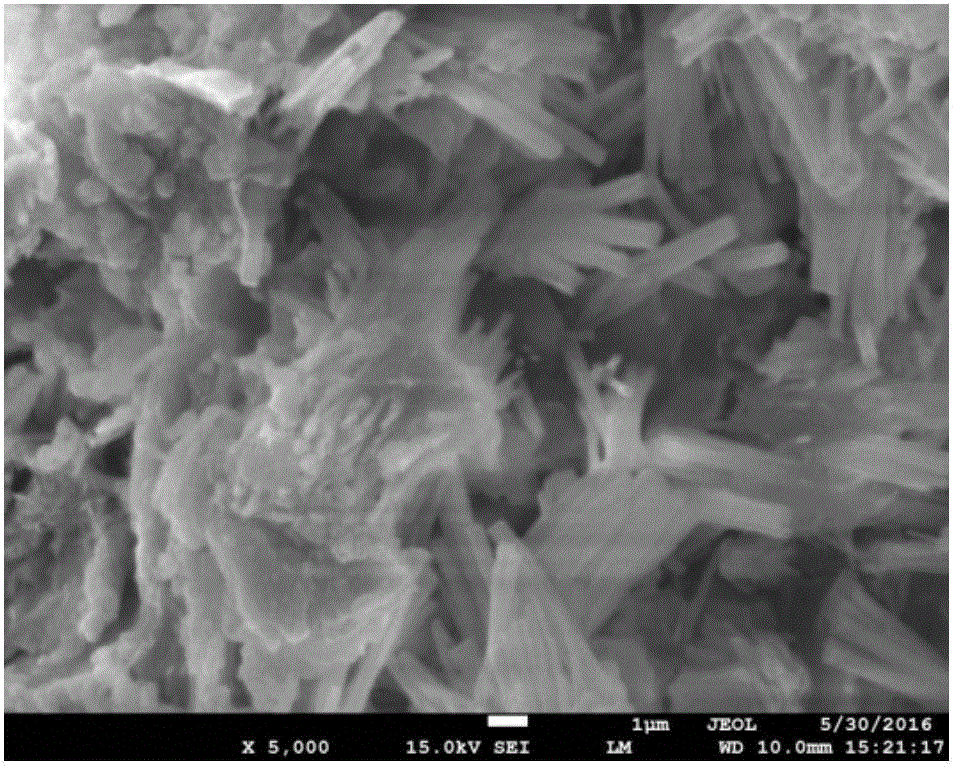

Image

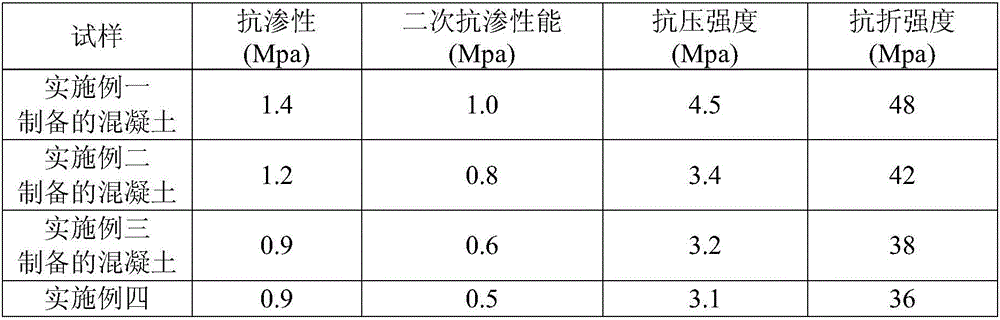

Examples

Embodiment 1

[0015] After fully mixing magnesium chloride powder and calcium chloride powder according to the mass ratio of 1:2, add water until the powder is completely dissolved, then add 2.2kg of ammonia water for each liter of mixed solution, stir thoroughly, filter and collect the precipitate, wash with distilled water, dry, and dry at 700 Calcined at ℃ for 4 hours to obtain high-activity nano-magnesia-calcium oxide composite powder; raise the temperature of 120g / L tetrasodium iminodisuccinate solution to 33℃, and add 280g of high-activity nano-sized magnesia-calcium oxide composite powder per liter of solution Stir at a temperature of 90°C for 30 minutes, cool to room temperature, and then dry to obtain high-activity nano-scale magnesium oxide calcium oxide composite powder and tetrasodium iminodisuccinate; Powdered sodium silicate, high-activity nano-scale magnesium oxide calcium oxide composite powder and tetrasodium iminodisuccinate are mixed according to the mass ratio of 40:60:50...

Embodiment 2

[0017] After fully mixing magnesium chloride powder and calcium chloride powder according to the mass ratio of 1:2.5, add water until the powder is completely dissolved, then add 2.5kg of ammonia water for each liter of mixed solution, stir well, filter and collect the precipitate, wash and dry with distilled water, and then dry it at 700 Calcined at ℃ for 4 hours to obtain high-activity nano-magnesia-calcium oxide composite powder; raise the temperature of 120g / L tetrasodium iminodisuccinate solution to 35℃, and add 300g of high-activity nano-sized magnesia-calcium oxide composite powder per liter of solution Stir at a temperature of 90°C for 30 minutes, cool to room temperature, and then dry to obtain high-activity nano-scale magnesium oxide calcium oxide composite powder and tetrasodium iminodisuccinate; Powdered sodium silicate, high-activity nano-scale magnesium oxide calcium oxide composite powder and tetrasodium iminodisuccinate are mixed according to the mass ratio of 4...

Embodiment 3

[0019] After fully mixing the magnesium chloride powder and calcium chloride powder according to the mass ratio of 1:2, add water until the powder is completely dissolved, add 1.8kg of ammonia water per liter of the mixed solution, stir thoroughly, filter and collect the precipitate, wash with distilled water, dry, and then dry at 650 Calcined at ℃ for 2 hours to obtain high-activity nano-magnesia-calcium oxide composite powder; raise the temperature of 120g / L tetrasodium iminodisuccinate solution to 33℃, and add 200g of high-activity nano-sized magnesia-calcium oxide composite powder per liter of solution Stir at a temperature of 80°C for 30 minutes, cool to room temperature and dry to obtain a high-activity nano-scale magnesium oxide calcium oxide composite powder and tetrasodium iminodisuccinate; Powdered sodium silicate, high-activity nano-sized magnesium oxide calcium oxide composite powder and tetrasodium iminodisuccinate are mixed according to the mass ratio of 40:55:50,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com