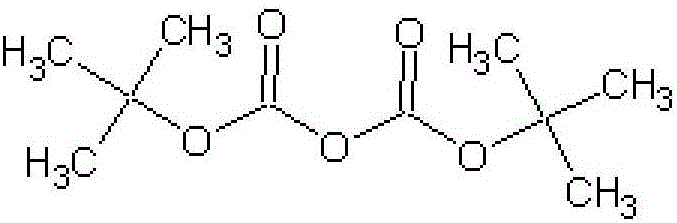

Synthetic method of di-tert-butyl dicarbonate

A technique for the synthesis of di-tert-butyl ester, which is applied in the preparation of carbon dioxide or inorganic carbonate, organic chemistry, reagents, etc., can solve the problems of cumbersome production steps, high risk factor, difficult product purification, etc., and achieve convenient solvent recovery and treatment , Simplify the experimental steps, and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The synthetic method of di-tert-butyl dicarbonate is as follows:

[0021] (1) use N 2 Empty the autoclave with a capacity of 2L, add 85g of tert-butanol, 650g of n-hexane, and 25g of sodium metal successively, heat to 110°C, and stir rapidly. At this time, the pressure in the autoclave is about 0.2MPa. React for 5-6 hours, and when there is no change in the pressure in the kettle for 15 minutes, the preparation of sodium tert-butoxide is completed;

[0022] (2) Cool down to -5 ~ 5 ℃, open the vent valve, and introduce CO 2 , until CO 2 No more absorption, continue to stir for 20 minutes after ventilation, keep the temperature constant, add 1g of pyridine, dissolve triphosgene with 65g of n-hexane, and then add it dropwise into the reaction kettle for about 3 to 4 hours, keep the temperature constant, - Insulate at 5-5°C for 1 hour, raise the temperature to 25-30°C and hold for 2 hours, remove the solvent at 80-90°C under normal pressure (whether it refers to distilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com