Method using 5-hydroxymethylfurfural to prepare 2,5-furandicarboxylic acid

A technology of hydroxymethyl furfural and furandicarboxylic acid is applied in the field of preparation of 2,5-furandicarboxylic acid and achieves the effects of good stability, high yield and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

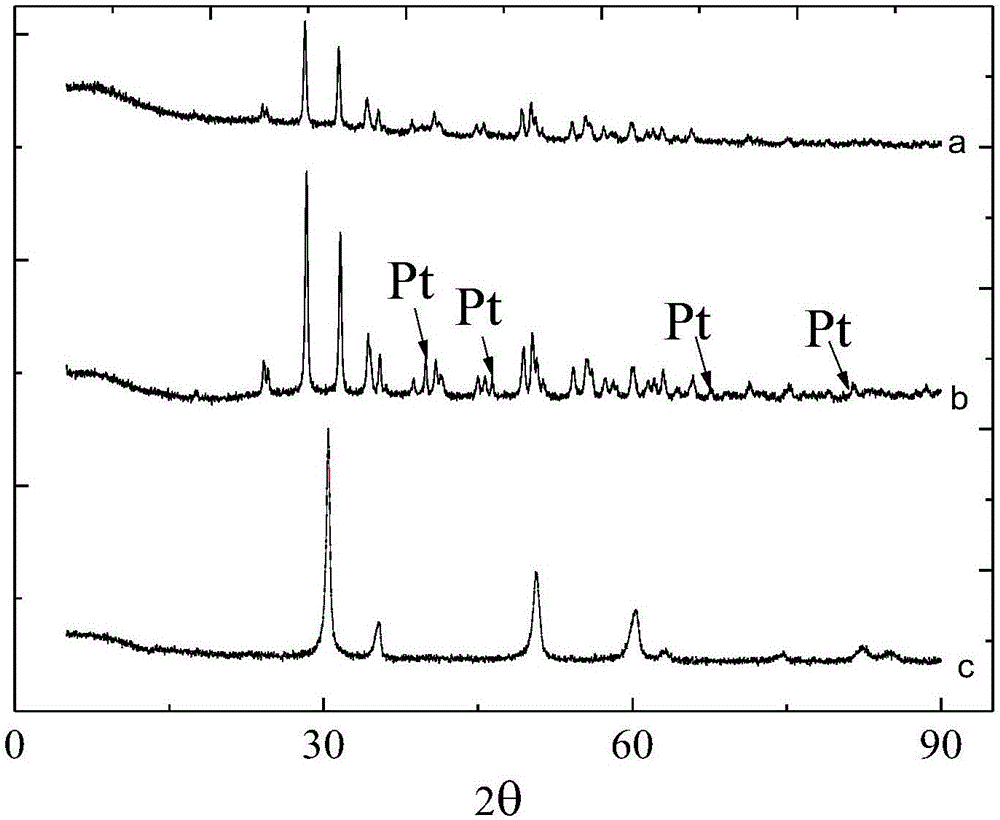

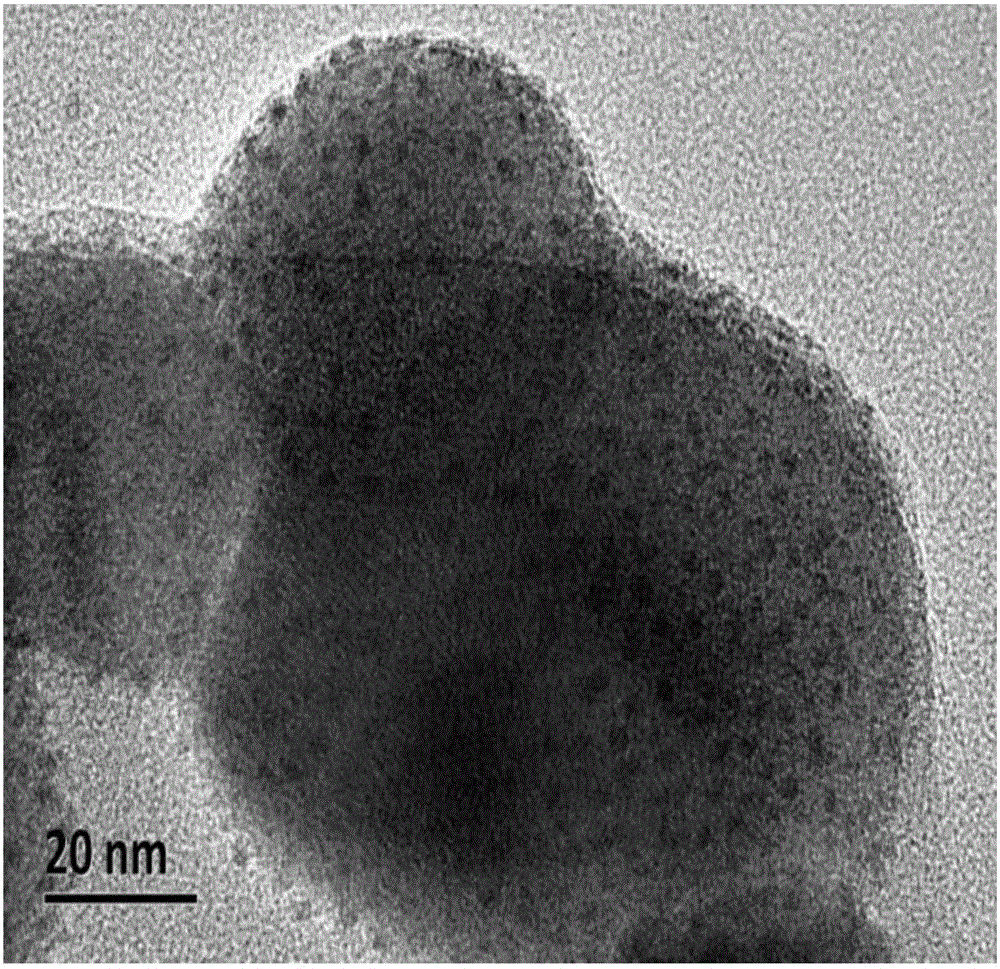

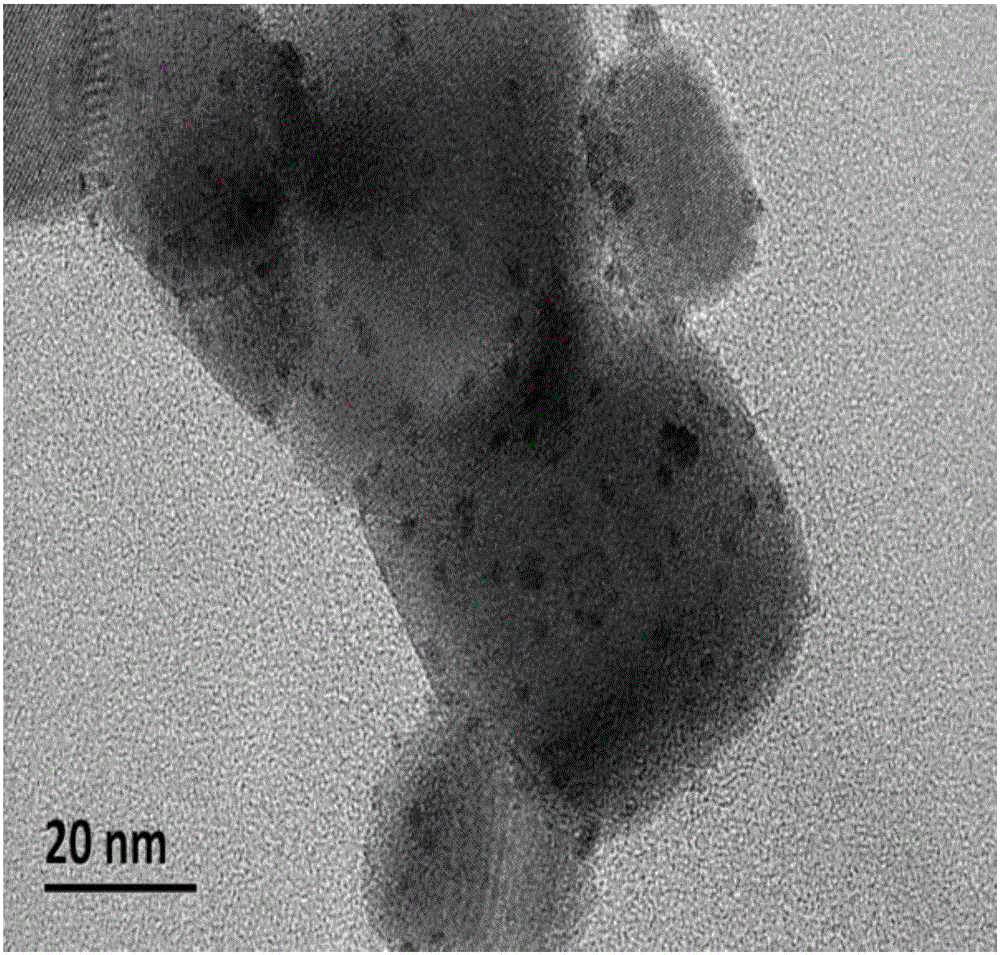

[0027] Take an appropriate amount of zirconia and add it to ethanol for ultrasonic dispersion, evenly spread it on the quartz plate with a dropper, and heat it with an infrared lamp to remove the ethanol. Put the quartz wafer into the deposition chamber, the temperature of the deposition chamber is set at 280 ° C, the platinum source is trimethylcyclopentadiene platinum, the temperature of the platinum source is set at 75 ° C, nitrogen is used as the carrier gas and purification gas, and ozone is the precursor , depositing Pt with different numbers of circles (5, 10, 20, 30 and 50 circles), the Pt content detected by ICP-MS is 0.75-6.10wt%.

[0028] The catalyzed oxidation reaction of 5-hydroxymethylfurfural is carried out in a 5mL stainless steel reactor, heated in an oil bath, and magnetically stirred, and sequentially added to a 5mL stainless steel high-temperature and high-pressure reactor Reaction conditions: catalyst 10mg, raw material 5-hydroxymethylfurfural 15mg , solv...

Embodiment 6~11

[0034] Take an appropriate amount of zirconia and add it to ethanol for ultrasonic dispersion, evenly spread it on the quartz plate with a dropper, and heat it with an infrared lamp to remove the ethanol. Put the quartz wafer into the deposition chamber, the temperature of the deposition chamber is set at 280 ° C, the platinum source is trimethylcyclopentadiene platinum, the temperature of the platinum source is set at 75 ° C, nitrogen is used as the carrier gas and purification gas, and ozone is the precursor , deposited for 30 laps, and the platinum content was determined to be 3.23wt% by ICP-MS.

[0035] Reaction conditions: 10 mg of catalyst, 15 mg of raw material 5-hydroxymethylfurfural, 3 mL of solvent water, different reaction temperatures (20, 40, 60, 80, 100 and 120 °C), oxygen The pressure is 0.4Mpa, the rotation speed is 600r / min, and the reaction time is 2h. The reaction results are shown in Table 2.

[0036] Table 2, the impact of different reaction temperatures ...

Embodiment 12~15

[0041] Take an appropriate amount of zirconia and add it to ethanol for ultrasonic dispersion, evenly spread it on the quartz plate with a dropper, and heat it with an infrared lamp to remove the ethanol. Put the quartz wafer into the deposition chamber, the temperature of the deposition chamber is set at 280 ° C, the platinum source is trimethylcyclopentadiene platinum, the temperature of the platinum source is set at 75 ° C, nitrogen is used as the carrier gas and purification gas, and ozone is the precursor , deposited for 30 laps, and the platinum content was determined to be 3.23wt% by ICP-MS.

[0042] Reaction conditions: 10 mg of catalyst, 15 mg of raw material 5-hydroxymethylfurfural, 3 mL of solvent water, 100 ° C reaction temperature, different oxygen pressures (0, 0.2, 0.4 and 0.6 MPa), The rotating speed is 600r / min, the reaction time is 2h, and the reaction results are shown in Table 3.

[0043] Table 3, the impact of different oxygen pressures on the reaction re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com