Production process for ampicillin sodium crystal

A technology of ampicillin sodium and production process, applied in the direction of organic chemistry, can solve the problems of long sublimation drying time, long freezing time, low freezing temperature, etc., and achieve the effect of shortening the sublimation drying time, facilitating sublimation, and increasing the sublimation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

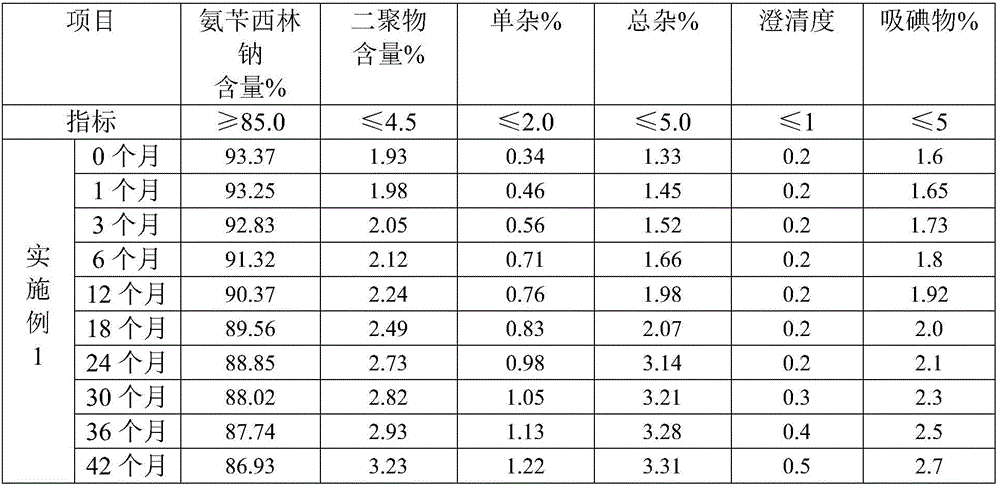

Embodiment 1

[0026] Prepare the following raw materials: Ampicillin 60g, 10% NaOH solution (density 1.1g / cm 3 ) 54ml, water for injection 55ml, tert-butanol (density 0.81g / ml) 13ml, vitamin C 2g, EDTA-disodium 0.2g.

[0027]Specific process operation steps: add 55ml of water for injection at 0-5°C and 13ml of tert-butanol into the reactor, start stirring, add 60g of ampicillin and 0.2g of EDTA-disodium in turn and stir to form a suspension solution, slowly add 10ml of water below 4°C % sodium hydroxide solution 54ml until the solution is translucent, the pH value at the end of the solution is controlled at 9.3 After the reaction is completed, add vitamin C2g and activated carbon with a total solution volume of 1-3‰ in the reactor and stir evenly. After decarburization and 0.2um precision filtration, the solution that has completed the reaction is evenly poured into the tray of the freeze-drying equipment, the freeze-drying process is started, the temperature of the solution is lowered to -...

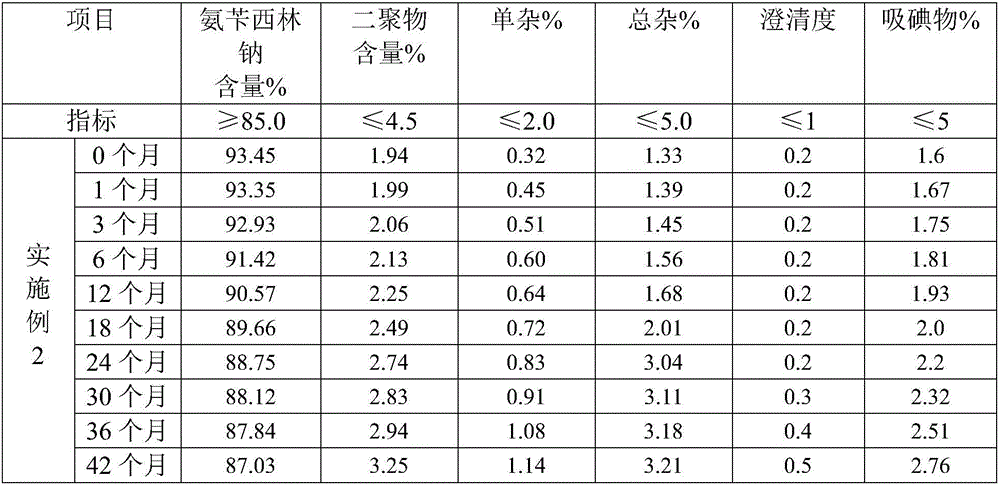

Embodiment 2

[0029] Prepare the following raw materials: Ampicillin 40g, 10% NaOH solution (density 1.1g / cm 3 ) 38ml, water for injection 35ml, tert-butanol (density 0.81g / ml) 12ml, vitamin C1g, EDTA-disodium 0.1g.

[0030] Specific process operation steps: add 35ml of water for injection at 1-4°C and 12ml of tert-butanol into the reactor, start stirring, add 40g of ampicillin and 0.4g of EDTA-disodium in turn and stir to form a suspension solution, slowly add 10ml of water below 3°C % sodium hydroxide solution 38ml until the solution is translucent, the pH value of the solution end point is controlled at 9.7 After the reaction is completed, add vitamin C1g and activated carbon with a total solution volume of 1-3‰ in the reactor and stir evenly. After decarburization and 0.2um precision filtration, the solution that has completed the reaction is evenly poured into the tray of the freeze-drying equipment, the freeze-drying process is started, the temperature of the solution is lowered to -3...

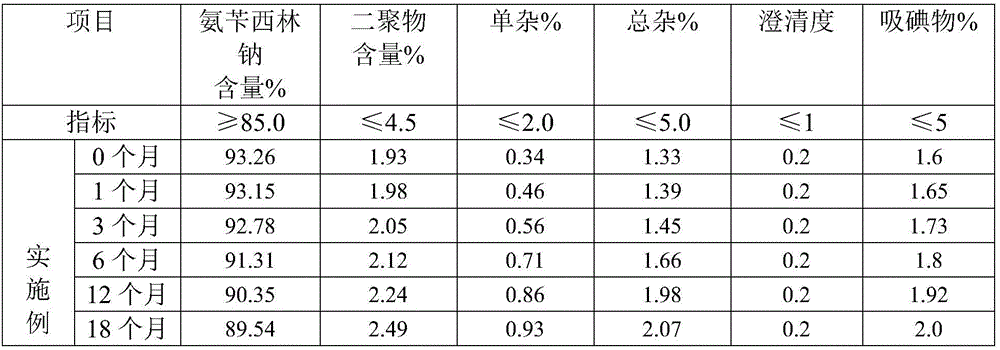

Embodiment 3

[0032] Prepare the following raw materials: Ampicillin 45g, 10% NaOH solution (density 1.1g / cm 3 ) 40ml, water for injection 40ml, tert-butanol (density 0.81g / ml) 14ml, vitamin C 1.3g, EDTA-disodium 0.13g.

[0033] Specific process steps: Add 40ml of water for injection at 2-3°C and 14ml of tert-butanol into the reactor, start stirring, add 45g of ampicillin and 0.13g of EDTA-disodium in turn and stir to form a suspension solution, slowly add 10 ml of water below 4°C 40ml of sodium hydroxide solution until the solution is translucent, and the pH value at the end of the solution is controlled at 9.6. After the reaction is completed, add 1.3g of vitamin C and activated carbon with a total volume of 1-3‰ of the solution in the reactor and stir evenly. After decarburization and 0.2um precision filtration, the solution that has completed the reaction is evenly poured into the tray of the freeze-drying equipment, the freeze-drying process is started, the temperature of the solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com