Preparation method of chitosan gel bead

A chitosan gel, chitosan technology, applied in the direction of organic dyes, etc., can solve the problems of poor mechanical strength of drugs, uncertain gel shape, damage to the encapsulation structure, etc., achieving less leakage, reducing manufacturing difficulty, Good package stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

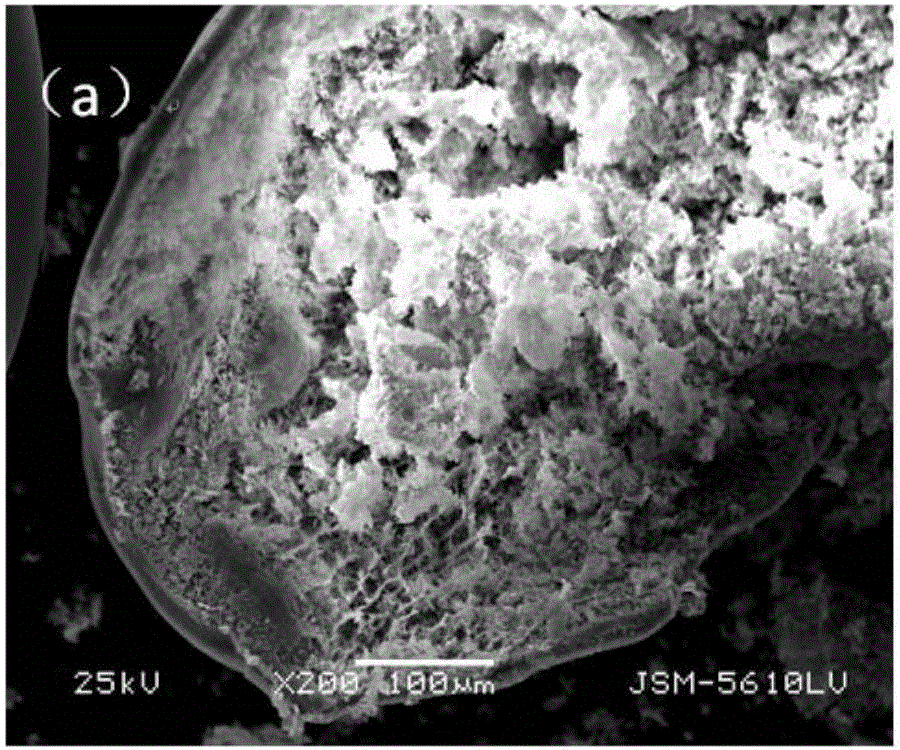

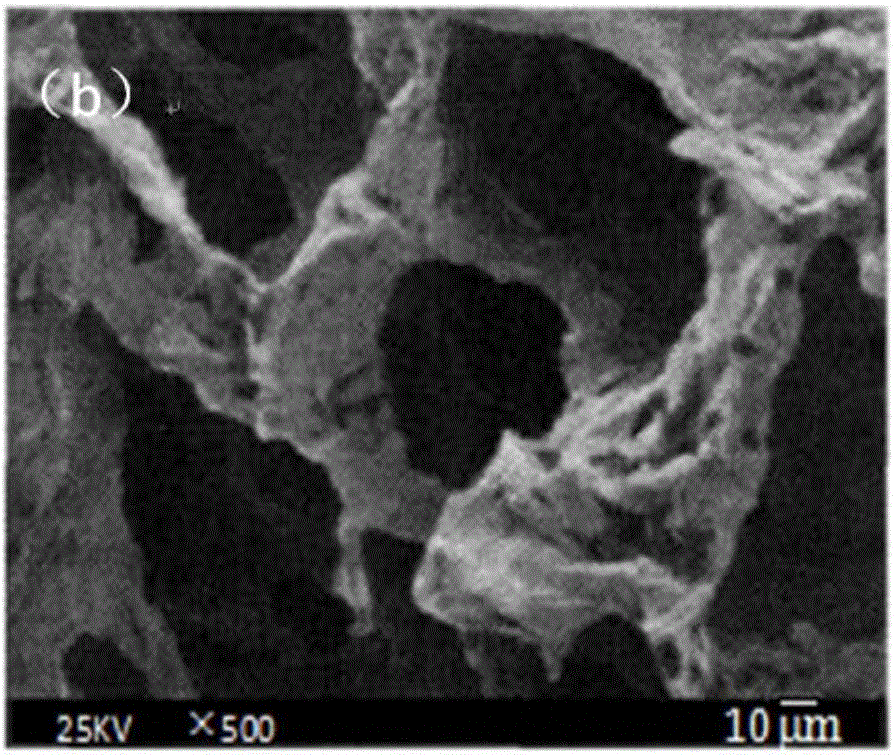

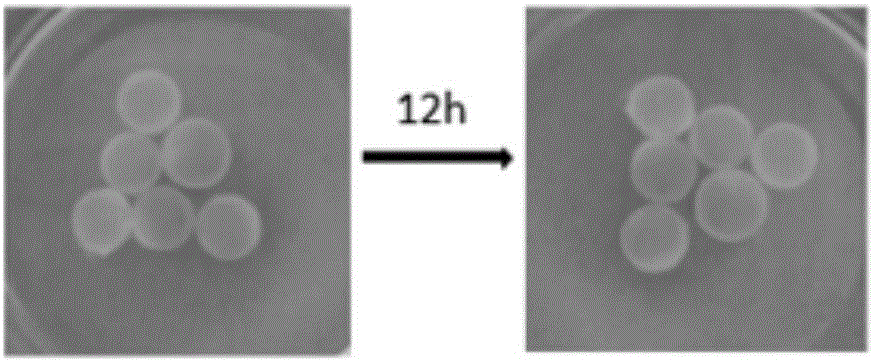

Image

Examples

Embodiment 1

[0038] Dissolve 1.4g of β-glycerophosphate sodium pentahydrate in 2mL of water, and dissolve 0.4g of medium-viscosity chitosan with a viscosity of 200-400mPa.s in 0.1mol / L acetic acid solution. Stirring is accelerated for rapid dissolution. After dissolving, let stand to make the air bubbles in the chitosan solution disperse completely. Weigh 25g of disodium hydrogen phosphate solid and dissolve it in 100ml of water to obtain a saturated disodium hydrogen phosphate solution. Under the ice-water bath, slowly add β-glycerophosphate sodium pentahydrate solution dropwise to the dissolved chitosan solution, after the dropwise addition is completed, adjust the pH value to between 6.9-7.1 with saturated disodium hydrogen phosphate solution, A chitosan / β-sodium glycerophosphate mixed solution (CS / β-GP mixed solution) was obtained. Weigh 0.2g-0.8g of sodium lauryl sulfate solid and dissolve it in 20mL of water to prepare a 2% sodium lauryl sulfate solution as a receiving solution. U...

Embodiment 2

[0040] According to embodiment 1 formula, change curing time is 50min, and its condition is constant. Prepare the capsule-shaped chitosan gel beads that this case implements according to the step of Example 1. The dosage of β-glycerophosphate sodium pentahydrate is 1.4g, the dosage of medium viscosity chitosan is 0.4g, the concentration of acetic acid is 0.1mol / L, the pH value is adjusted between 6.9-7.1, the dosage of sodium lauryl sulfate 0.2g, the water bath temperature is 42°C, and the water bath time is 5min. Chitosan gel beads with excellent gel effect can also be obtained.

Embodiment 3

[0042] According to the formula of Example 1, changing the aging time is 60min, and its condition is constant. Prepare the capsule-shaped chitosan gel beads that this case implements according to the step of Example 1. The dosage of β-glycerophosphate sodium pentahydrate is 1.4g, the dosage of medium viscosity chitosan is 0.4g, the concentration of acetic acid is 0.1mol / L, the pH value is adjusted between 6.9-7.1, the dosage of sodium lauryl sulfate 0.2g, the water bath temperature is 42°C, and the water bath time is 5min. Chitosan gel beads with excellent gel effect can also be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com