Special semi-steel radial tire for microvan and preparation method of special semi-steel radial tire

A technology for radial tires and vans, applied to special tires, tire parts, vehicle parts, etc., can solve the problems of high manufacturing requirements, poor lateral stability, and large sidewall deformation of radial tires, and achieve thermal and oxygen aging resistance and anti-aging Good ozone aging performance, good lateral stability, and small sidewall deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

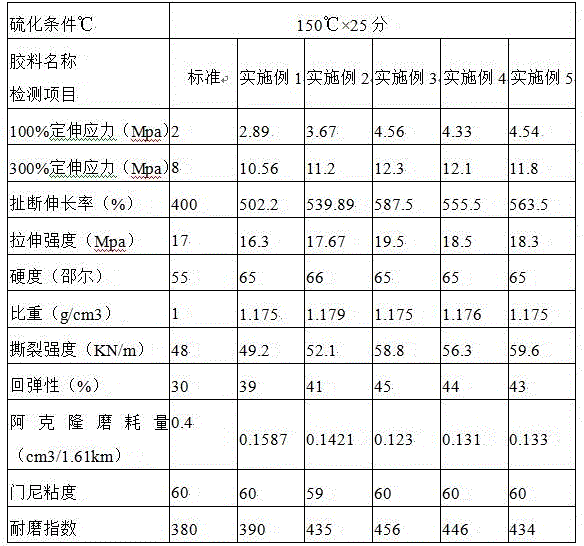

Examples

Embodiment 1

[0022] Embodiment 1, a special tire for miniature vans, calculated in parts by weight, including 40 parts of natural rubber, 20 parts of solution-polymerized styrene-butadiene rubber, 15 parts of butadiene rubber, 35 parts of nitrile rubber, 1.5 parts of glass fiber, white carbon black 20 parts, 2 parts of silane coupling agent, 35 parts of carbon black, 5 parts of aromatic oil, 4 parts of zinc oxide, 1.5 parts of stearic acid, 1 part of anti-aging agent, 1 part of microcrystalline wax, 10 parts of functional resin, carbon black dispersion 2 parts of agent, 1.5 parts of sulfur, 1 part of accelerator, 0.1 part of anti-scorch agent, 1.5 parts of benzoic acid, 7.8 parts of phenolic resin, C 5 5.5 parts of petroleum resin, 5.5 parts of a mixture of Rhine new TT 100, Rhine plastic PP, and phosphate plasticizer.

[0023] The glass fiber is a mixture of glass fibers with a diameter of 20-25 μm and a diameter of 60-65 μm, and the weight ratio of the glass fibers with a diameter of 20-...

Embodiment 2

[0038] Embodiment 2, a special tire for miniature vans, calculated in parts by weight, including 60 parts of natural rubber, 30 parts of solution-polymerized styrene-butadiene rubber, 20 parts of butadiene rubber, 40 parts of nitrile rubber, 2.5 parts of glass fiber, white carbon black 40 parts, 4 parts of silane coupling agent, 45 parts of carbon black, 8 parts of aromatic oil, 8 parts of zinc oxide, 4.5 parts of stearic acid, 5 parts of anti-aging agent, 3 parts of microcrystalline wax, 20 parts of functional resin, carbon black dispersion 5 parts of agent, 3.5 parts of sulfur, 3 parts of accelerator, 0.3 parts of anti-scorch agent, 3.5 parts of benzoic acid, 12.4 parts of phenolic resin, C 5 8.3 parts of petroleum resin, 8.5 parts of a mixture of Rhine new TT 100, Rhine plastic PP, and phosphate plasticizer.

[0039] The glass fiber is a mixture of glass fibers with a diameter of 20-25 μm and a diameter of 60-65 μm, and the weight ratio of the glass fibers with a diameter o...

Embodiment 3

[0054] Embodiment 3, a special tire for miniature vans, calculated by weight, including 50 parts of natural rubber, 25 parts of solution-polymerized styrene-butadiene rubber, 17.5 parts of butadiene rubber, 37.5 parts of nitrile rubber, 2 parts of glass fiber, white carbon black 30 parts, 3 parts of silane coupling agent, 40 parts of carbon black, 6.5 parts of aromatic oil, 6 parts of zinc oxide, 3 parts of stearic acid, 3 parts of anti-aging agent, 2 parts of microcrystalline wax, 15 parts of functional resin, carbon black dispersion 3.5 parts of agent, 2.5 parts of sulfur, 2 parts of accelerator, 0.2 parts of anti-scorch agent, 2.5 parts of benzoic acid, 10.1 parts of phenolic resin, C 5 5.5-8.3 parts of petroleum resin, 7 parts of a mixture of Rhine New TT 100, Rhine Plastic PP, and phosphate plasticizer.

[0055] The glass fiber is a mixture of glass fibers with a diameter of 20-25 μm and a diameter of 60-65 μm, and the weight ratio of the glass fibers with a diameter of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com