Polystyrene abrasion-resistant integrated ultra-hydrophobic coating and preparation method thereof

A technology of polystyrene and polystyrene emulsion, applied in coatings, anti-corrosion coatings, etc., can solve the problems of high polystyrene super double coating process requirements, difficulty in integrated preparation, poor wear resistance, etc. Achieve strong binding force, high hardness and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

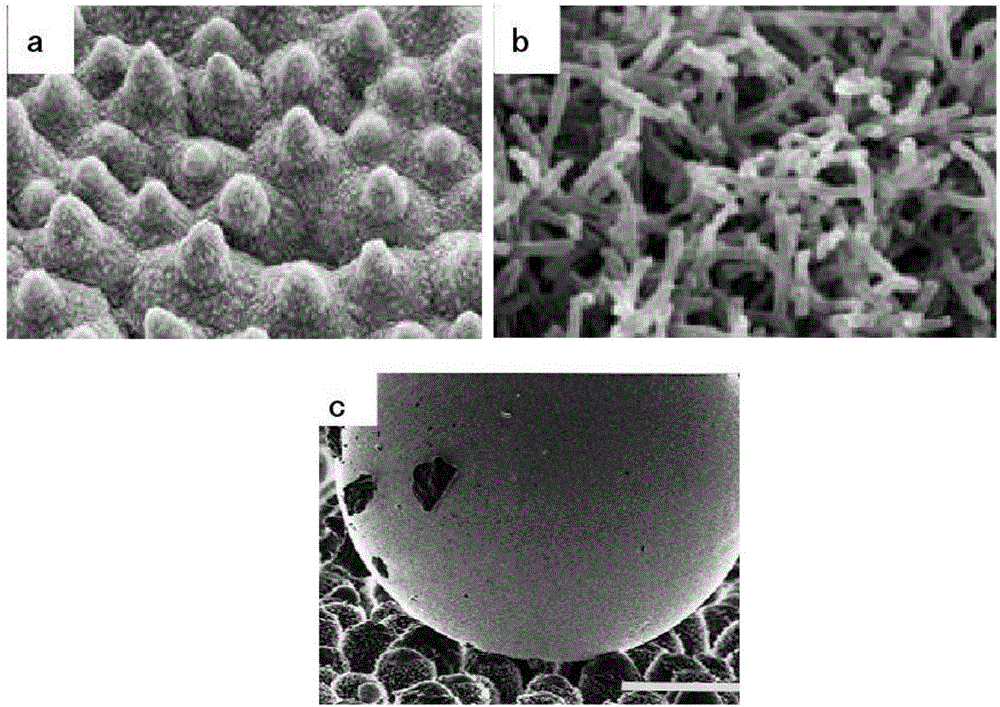

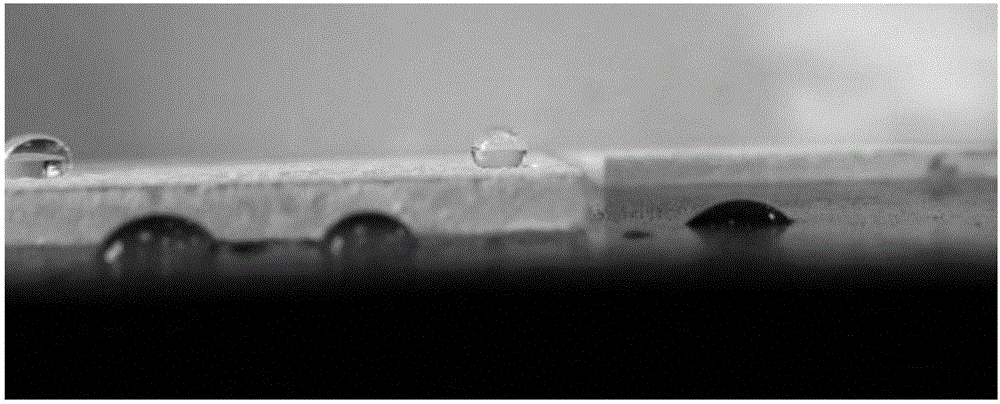

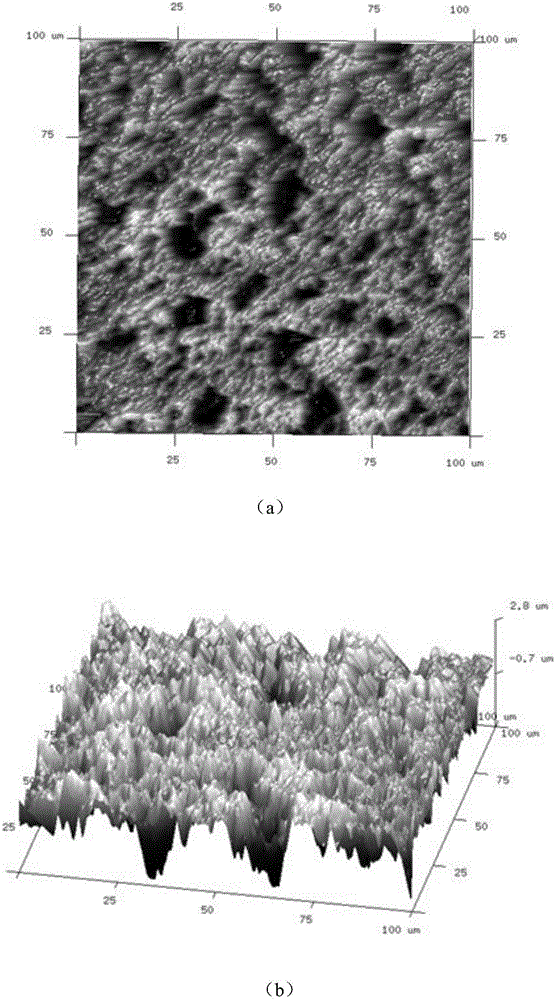

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: Polystyrene wear-resistant integrated super-hydrophobic coating, the steps are as follows:

[0052] 1. Stir the polystyrene emulsion with magnetic force, the heating temperature is 120°C, the stirring rate is 1000r / min, the stirring time is 0.5h, and then stand still for 5h to fully open the molecular chain of the emulsion;

[0053] 2. Add 30% (mass percent) n-butanol and 45% (mass percent) N,N-dimethylacetamide to the polystyrene emulsion for modification to obtain a polystyrene diluted emulsion, adding 15% by mass PTFE (solid content 15%, mass percentage), stirring, mixing, stirring rate 800r / min, stirring time 1.5h, to obtain mixture 1; wherein the percentage is the mass percentage of polystyrene dilute emulsion;

[0054] 3. Mix the mixture 1 obtained in step 2 with dimethyl sulfone in a mass ratio of 1:2, add methanol to dissolve into a jelly, and disperse it ultrasonically for 15 minutes;

[0055] 4. Add nano-silica particles to the colloid prepared ...

Embodiment 2

[0063] Embodiment 2: Polystyrene wear-resistant integrated superhydrophobic coating, the steps are as follows:

[0064] 1) Stir the polystyrene emulsion with magnetic force at a heating temperature of 60°C and a speed of 1400r / min, stir for 2 hours, and then let it stand for 5 hours to fully open the molecular chain of the emulsion;

[0065] 2) Add 30% (mass percent) n-butanol and 65% (weight percent) N,N-dimethylacetamide to the polystyrene emulsion for modification to obtain a polystyrene diluted emulsion, adding 15% by mass polytetrafluoroethylene (solid content 15%, mass percent), stirring, mixing, stirring rate 1400r / min, stirring time 4h, to obtain mixture 1; wherein the percentage is the mass percentage of polystyrene dilute emulsion;

[0066] 3) Mix the mixture 1 obtained in step 2 with dimethyl sulfone in a mass ratio of 1:4, add methanol to dissolve into a jelly, and disperse ultrasonically for 35 minutes;

[0067] 4) adding nano-silica particles to the colloid prep...

Embodiment 3

[0073] Embodiment 3: Polystyrene wear-resistant integrated superhydrophobic coating, the steps are as follows:

[0074] 1) Magnetically stir the polystyrene emulsion at a heating temperature of 100°C and a speed of 1200r / min, stir for 1.2 hours, and then let it stand for 5 hours to fully open the molecular chain of the emulsion;

[0075] 2) Add 30% (mass percent) n-butanol and 55% (weight percent) N,N-dimethylacetamide to the polystyrene emulsion for modification to obtain a polystyrene diluted emulsion, and then add 20% by mass polytetrafluoroethylene (solid content 15%, mass percent), stirring, mixing, stirring rate 1000r / min, stirring time 3h, to obtain mixture 1; wherein the percentage is all accounted for the mass percentage of polystyrene dilute emulsion;

[0076] 3) Mix the mixture 1 obtained in step 2 with dimethyl sulfone in a ratio of 1:3, add methanol to dissolve into a jelly, and disperse ultrasonically for 25 minutes;

[0077] 4) adding the nano-silica particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com