Roof energy-saving waterproof coating with fireproof function and preparation method thereof

A waterproof coating and functional technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of low fire ratings, achieve the effects of reduced heat absorption capacity, improved flame-retardant effect, and improved hemispherical emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

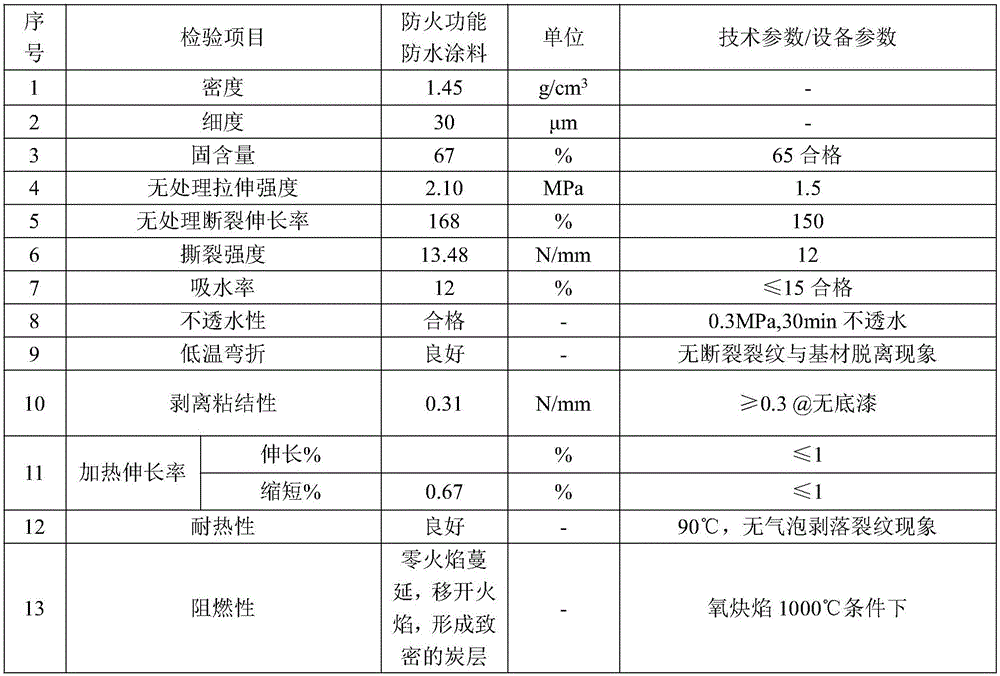

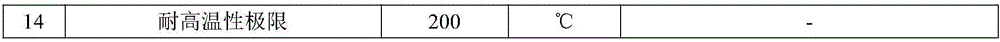

Examples

specific Embodiment approach 1

[0019] A roof energy-saving waterproof coating with fireproof function, the parts by weight of each component in the roof energy-saving waterproof paint with fireproof function are: 25 parts of solvent deionized water, 0.7 parts of dispersant, 0.3 parts of defoamer A 0.1 part of KH550 silane coupling agent, 17 parts of flame retardant filler, 8 parts of nano powder, 2 parts of alcohol ester twelve A, 0.1 part of thickener premix, 30 parts of acrylic emulsion, 0.3 part of defoamer B , 0.2 parts of alcohol ester twelve B, 0.2 parts of anti-mold additives, 0.2 parts of DMAE, and 1.5 parts of liquid thickener.

[0020] The dispersant described in this embodiment is formed by mixing Rohm and Haas OrotanTM 1850E and potassium tripolyphosphate according to a mass ratio of 5:1; Ammonium polyphosphate is mixed according to the mass ratio of 1:1:3; the nano-powder is rutile nano-TiO 2 and nano-ZnO, in which rutile nano-TiO 2 The mass ratio to nano ZnO is 15:1, rutile nano TiO 2 The p...

specific Embodiment approach 2

[0023] A roof energy-saving waterproof coating with fireproof function, the parts by weight of each component in the raw material of the roof energy-saving waterproof coating with fireproof function are: the weight of each component in the ceramic heat pipe thermal insulation coating raw material The parts are: 35 parts of solvent deionized water, 1 part of dispersant, 0.8 parts of defoamer A, 0.3 parts of KH550 silane coupling agent, 22 parts of flame retardant filler, 10 parts of nano powder, 3 parts of alcohol ester twelve A , 0.3 parts of thickener premix, 35 parts of acrylic emulsion, 0.8 parts of defoamer B, 0.5 parts of alcohol ester twelve B, 0.4 parts of anti-mold additives, 0.4 parts of DMAE, 3 parts of liquid thickener .

[0024] The dispersant described in this embodiment is formed by mixing Rohm and Haas OrotanTM 1850E and potassium tripolyphosphate according to a mass ratio of 5:1; Ammonium polyphosphate is mixed according to the mass ratio of 1:1:3; the nano-po...

specific Embodiment approach 3

[0027] A roof energy-saving waterproof coating with fireproof function, the parts by weight of the components in the raw materials of the roof energy-saving waterproof paint with fireproof function are: 22 parts of solvent deionized water, 0.7 parts of dispersant, and defoamer A0. 5 parts, 0.15 parts of KH550 silane coupling agent, 17 parts of flame retardant filler, 9 parts of nano powder, 2 parts of alcohol ester twelve A, 0.2 parts of thickener premix, 32 parts of acrylic emulsion, defoamer B0.5 part, 0.4 part of alcohol ester twelve B, 0.2 part of anti-mildew additive, 0.2 part of DMAE, and 2.5 parts of liquid thickener.

[0028]The dispersant described in this embodiment is formed by mixing Rohm and Haas OrotanTM 1850E and potassium tripolyphosphate according to a mass ratio of 5:1; Ammonium polyphosphate is mixed according to the mass ratio of 1:1:3; the nano-powder is rutile nano-TiO 2 and nano-ZnO, in which rutile nano-TiO 2 The mass ratio to nano ZnO is 15:2, rutile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com