Glue based on graphene modification

A graphene modification and graphene technology, applied in adhesives, chloroprene adhesives, adhesive types, etc., can solve the problems of anti-stripping, anti-cracking and impact resistance, long curing time, etc., to achieve High bonding strength at room temperature, convenient operation, and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

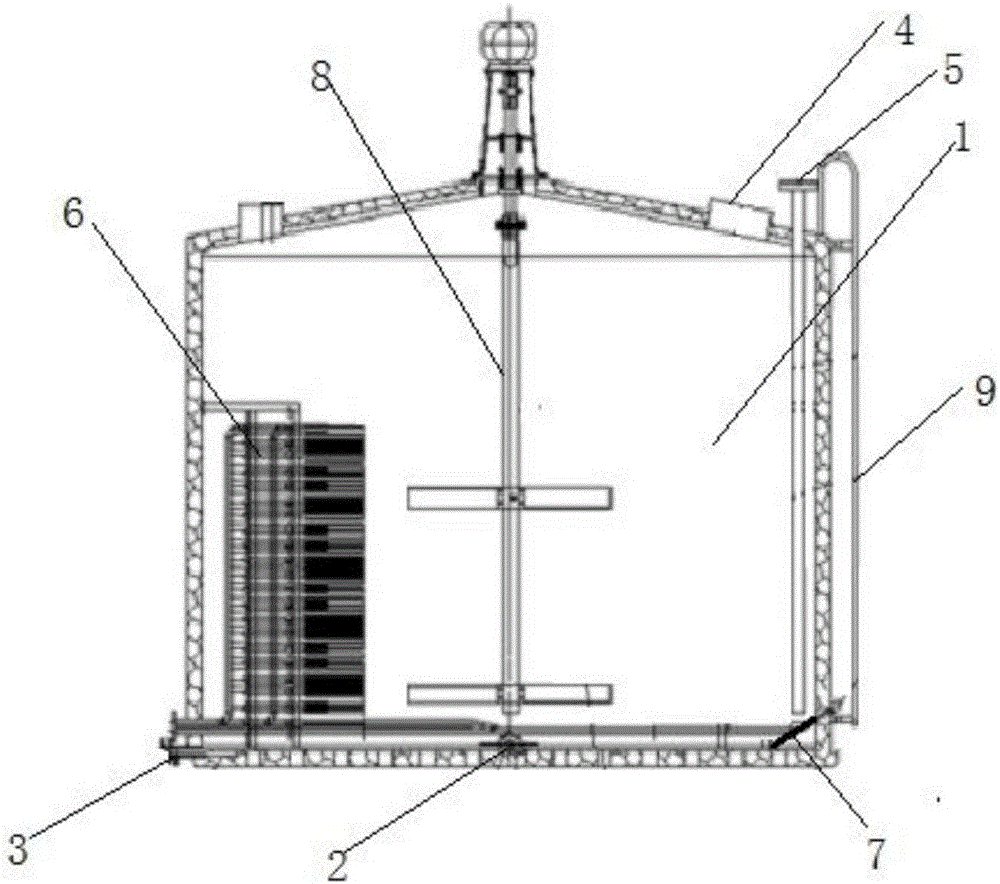

Image

Examples

Embodiment 1

[0028] A kind of glue based on graphene modification comprises by weight parts:

[0029] 30 parts of polyurethane, 15 parts of neoprene, 30 parts of polyacrylate, 2 parts of graphene, 1.6 parts of triallyl isocyanurate, 1 part of ethylenediamine, 10 parts of n-butanol, 2 parts of toluene, hard 3 parts of potassium fatty acid, 2 parts of polyvinylpyrrolidone, 5 parts of N-phenyl-β-naphthylamine;

[0030] The preparation method based on the graphene-modified glue is as follows:

[0031] Step (1): Add graphene into n-butanol and toluene, and disperse evenly by ultrasonic to obtain mixed solution A;

[0032] Step (2): Add polyurethane, neoprene and polyacrylate into the reactor, raise the temperature to 80°C, and react for 3 hours, then add the mixed solution A, triallyl isocyanurate in step (1) Ester, potassium stearate, polyvinylpyrrolidone and N-phenyl-β-naphthylamine were sequentially added to the reactor, the reaction temperature was adjusted to 150°C, and the reaction was ...

Embodiment 2

[0040] A kind of glue based on graphene modification comprises by weight parts:

[0041] 12 parts of polyurethane, 30 parts of neoprene, 15 parts of polyacrylate, 12 parts of graphene, 0.8 parts of triallyl isocyanurate, 6 parts of ethylenediamine, 2 parts of n-butanol, 8 parts of toluene, hard 0.8 parts of potassium fatty acid, 8 parts of polyvinylpyrrolidone, 1 part of N-phenyl-β-naphthylamine;

[0042] The preparation method based on the graphene-modified glue is as follows:

[0043] Step (1): Add graphene into n-butanol and toluene, and disperse evenly by ultrasonic to obtain mixed solution A;

[0044] Step (2): Add polyurethane, neoprene and polyacrylate into the reactor, raise the temperature to 105°C, and react for 1 hour, then add the mixed solution A, triallyl isocyanurate in step (1) Ester, potassium stearate, polyvinylpyrrolidone and N-phenyl-β-naphthylamine were sequentially added to the reactor, the reaction temperature was adjusted to 360°C, and the reaction wa...

Embodiment 3

[0052] A kind of glue based on graphene modification comprises by weight parts:

[0053] 16 parts of polyurethane, 25 parts of neoprene, 16 parts of polyacrylate, 10 parts of graphene, 1 part of triallyl isocyanurate, 5 parts of ethylenediamine, 4 parts of n-butanol, 6 parts of toluene, hard 1 part of potassium fatty acid, 6 parts of polyvinylpyrrolidone, 2 parts of N-phenyl-β-naphthylamine;

[0054] The preparation method based on the graphene-modified glue is as follows:

[0055] Step (1): Add graphene into n-butanol and toluene, and disperse evenly by ultrasonic to obtain mixed solution A;

[0056]Step (2): Add polyurethane, neoprene and polyacrylate into the reactor, raise the temperature to 100°C, and react for 2 hours, then add the mixed solution A, triallyl isocyanurate in step (1) Ester, potassium stearate, polyvinylpyrrolidone and N-phenyl-β-naphthylamine were sequentially added to the reactor, the reaction temperature was adjusted to 200°C, and the reaction was car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com